Pipe barrel and bottom valve assembling machine

A technology for assembly machines and bottom valves, applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as low efficiency, high cost, human factors affecting assembly quality, etc., and achieve high work efficiency , improve the quality of assembly, and achieve the effect of standardized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

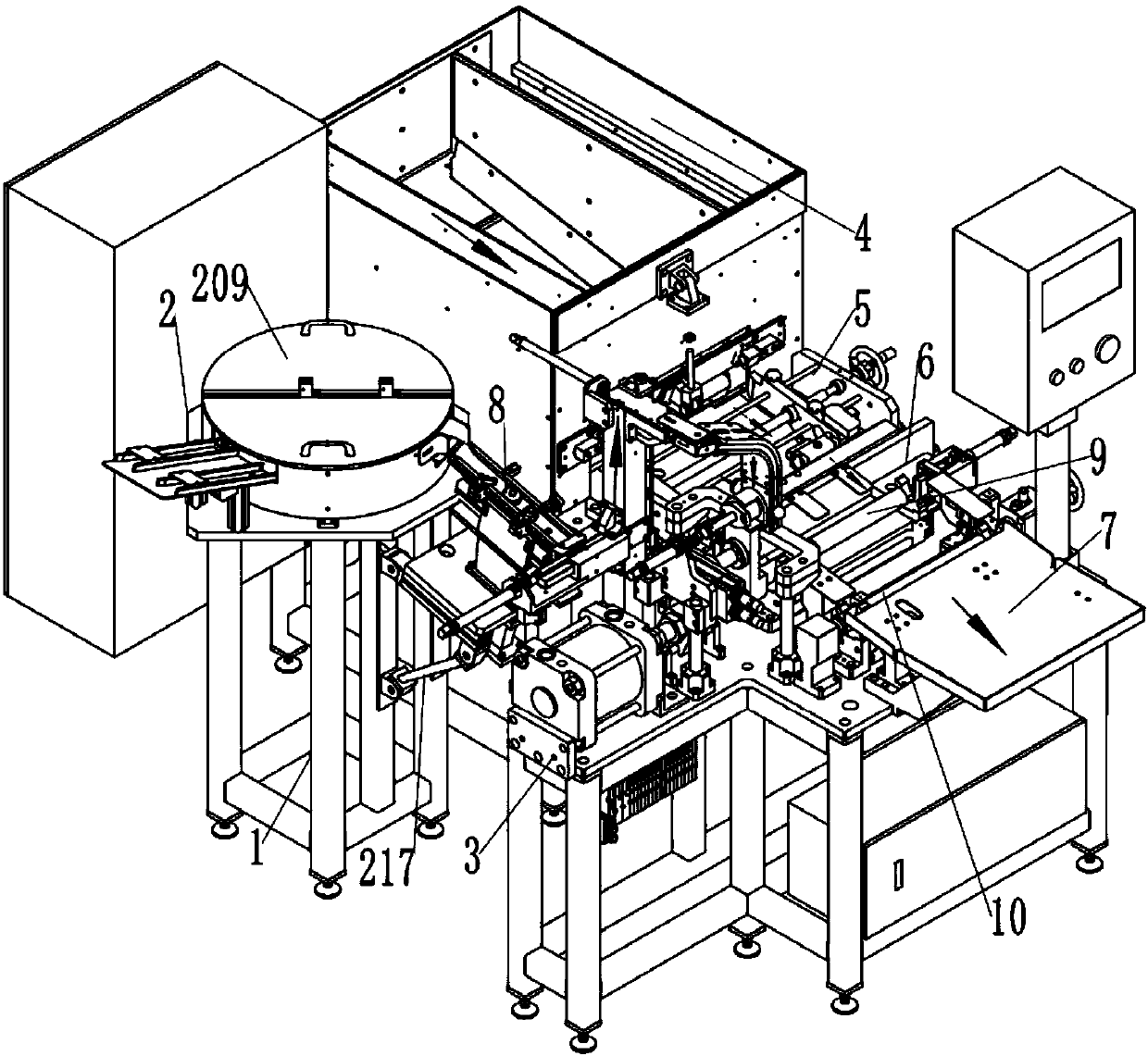

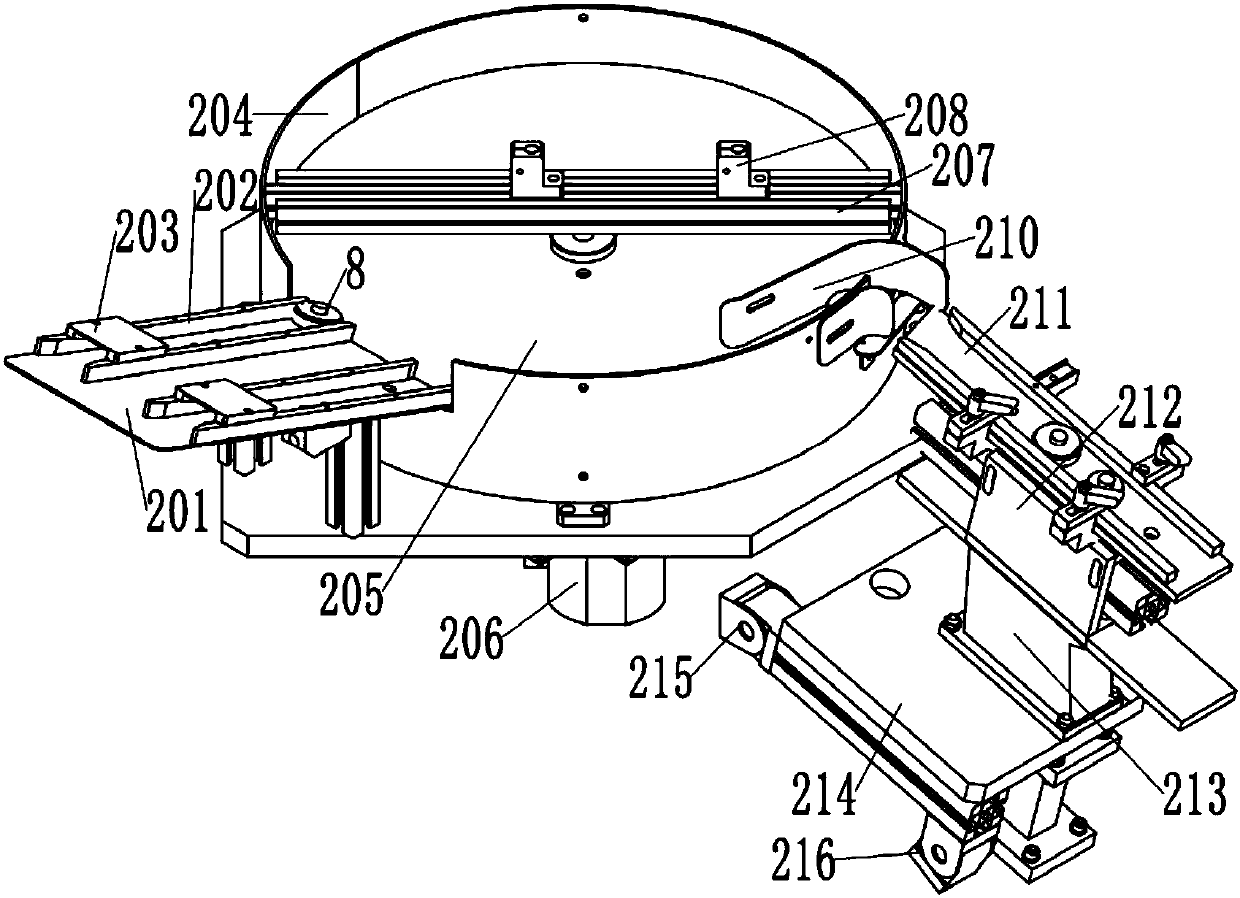

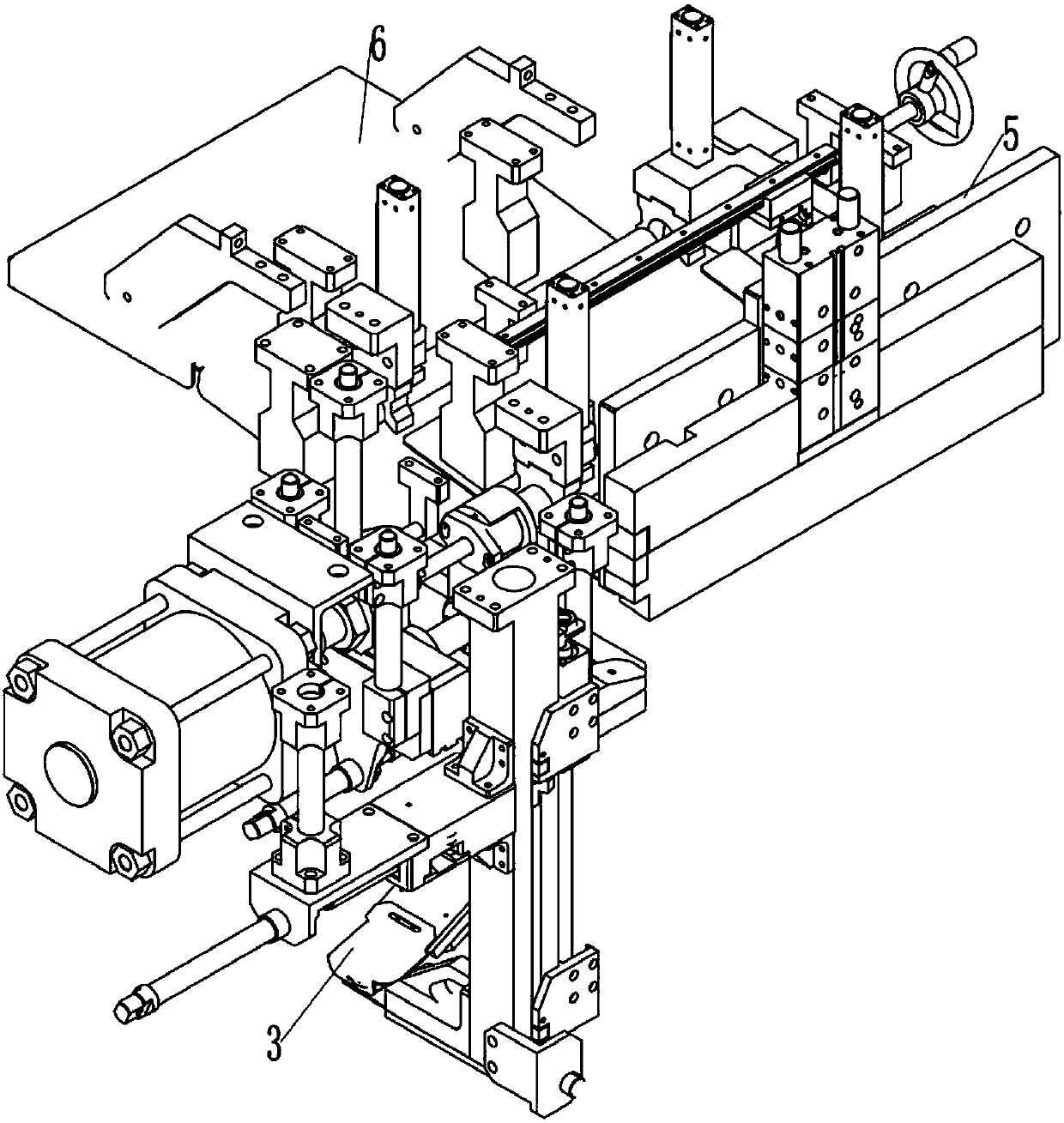

[0023] like Figure 1-11 As shown, the pipe barrel and bottom valve assembly machine of the present embodiment, such as figure 1 , including a frame 1, a bottom valve storage device 2 arranged on the frame 1 and used for storing and outputting the bottom valve 8 to be assembled, a tube tube storage device 4 for storing and outputting the tube tube 9 to be assembled, The tube conveying device 5 connected to the tube storage device 4 process, the bottom valve 8 to be assembled output by the bottom valve storage device 2 and the tube to be assembled 9 output by the tube conveying device 5 are assembled and pressure-holding tested The assembly center and the finished product output station 7 connected with the process of the assembly center;

[0024] The assembly center includes the bottom valve installation assembly 3 connected to the bottom valve storage device 2 process, and the assembly assembly 6 connected to the tube delivery device 5 process; the bottom valve 8 to be assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com