Novel sorting device for storing

A sorting device and warehousing technology, which is applied in the direction of storage device, transportation and packaging, conveyor objects, etc., can solve the problem of unstable clamping of the sorting device, and achieve the effect of easy sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

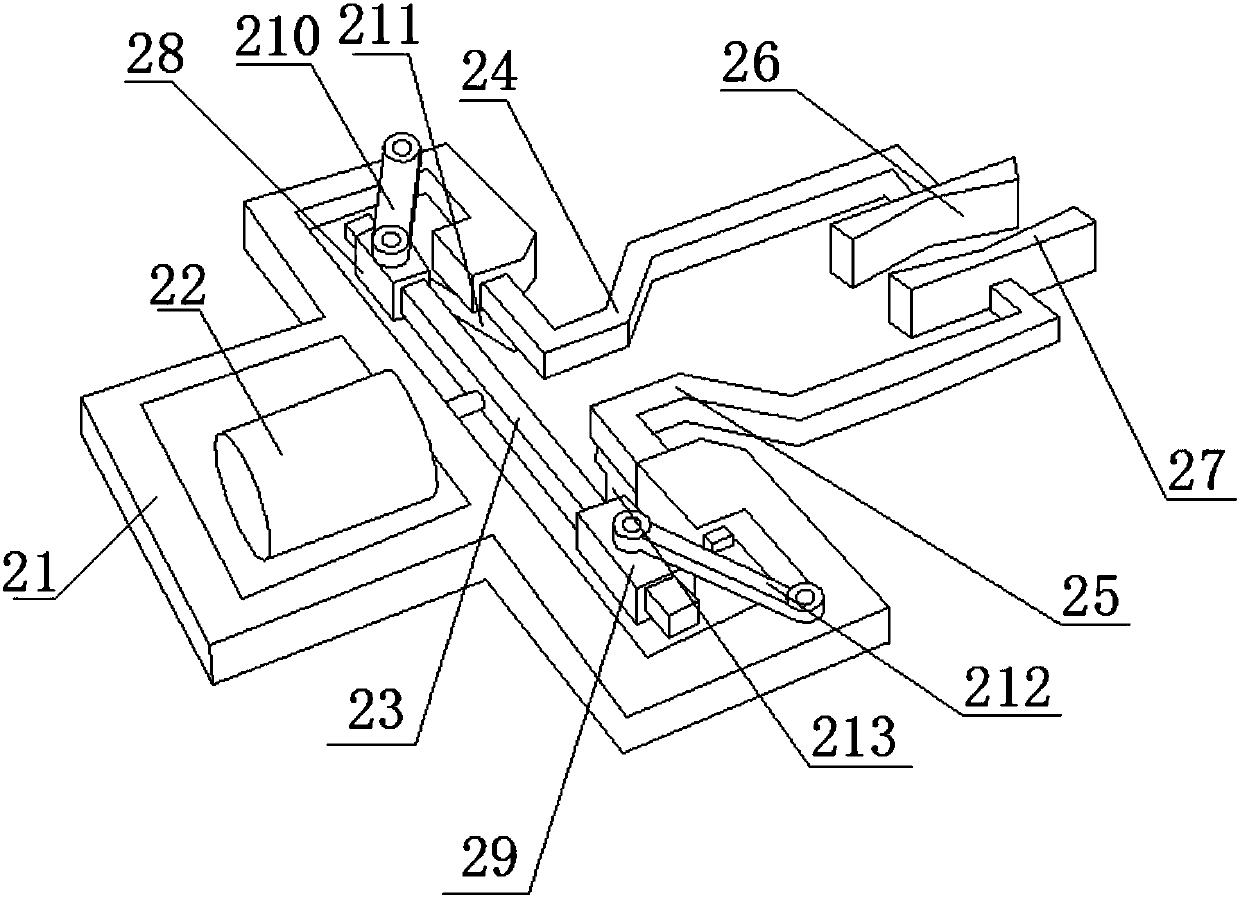

[0027] A new sorting device for storage, including a sorting manipulator and a universal moving mechanism, the sorting manipulator is connected to the universal moving mechanism, the sorting manipulator includes a frame, and a driving hydraulic cylinder is arranged on the frame , the output shaft of the drive hydraulic cylinder is connected with a connecting rod, the left and right ends of the frame are respectively provided with connecting holes, and the connecting holes are respectively provided with a clamping frame one, a clamping frame two, a clamping frame one, a clamping frame The second can move left and right along the connecting hole, the clamping frame 1 and the clamping frame 2 are respectively connected with the sorting handle 1 and the sorting handle 2, and the left and right sides of the connecting rod are provided with hollow sliders 1 and 2 , the hollow slider 1 and the hollow slider 2 can slide along the length direction of the connecting rod. The other end o...

Embodiment 2

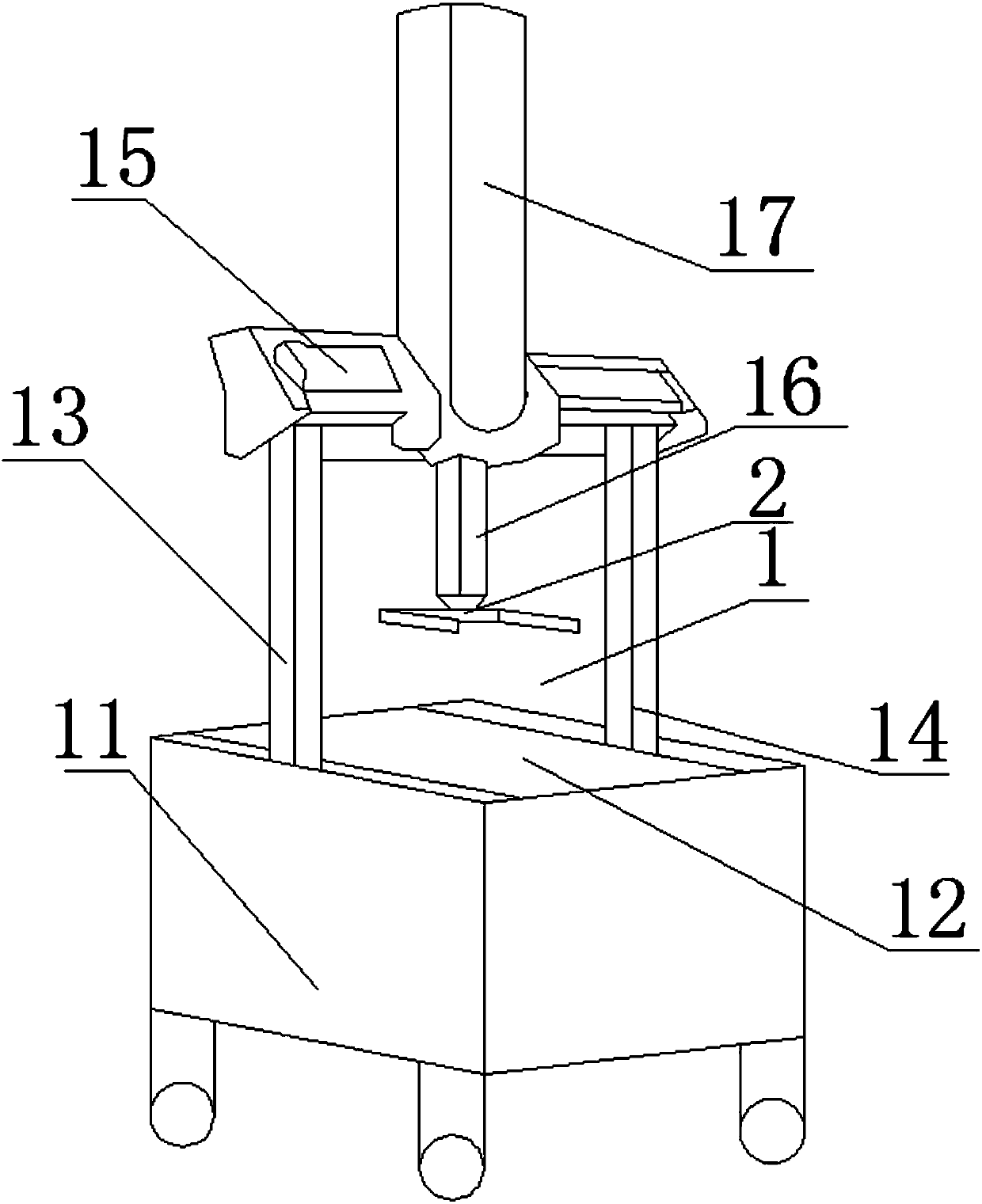

[0029] On the basis of Embodiment 1, the universal moving mechanism includes a base, a moving assembly is arranged under the base, a loading platform is arranged on the base, and chutes are respectively arranged on the left and right sides of the loading platform. The first moving column and the second moving column are arranged in the chute, a crossbeam is arranged between the first moving column and the second moving column, a guide rail is arranged on the crossbeam, a moving arm is set on the guide rail, and the moving arm Vertically arranged relative to the crossbeam and the moving arm can slide along the length direction of the guide rail, a driving cylinder is arranged in the moving arm, the output end of the driving cylinder can move in the vertical direction, and the output of the driving cylinder connected to the rack end. Through this setting, the moving component can drive the base to move freely, and the loading platform can be loaded with items. At the same time, ...

Embodiment 3

[0031] On the basis of the above-mentioned embodiments, the moving assembly includes four installation columns, the installation columns are connected to the base, universal wheels are connected under the installation columns, and a universal wheel for driving the universal wheels is also arranged under the installation columns. motor. Through this setting, it is convenient to move the base, so that the entire sorting device can move freely in the conveying space, and realize the flexible sorting of the sorting manipulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com