A kind of preparation method of 4,4'-diaminodiphenylmethane

A technology of diaminodiphenylmethane and aniline, which is applied in the field of chemical production, can solve the problems of complex product post-processing, complex catalyst preparation, high reaction temperature, etc., achieve high catalytic activity and stability, and is suitable for wide application and synthesis The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

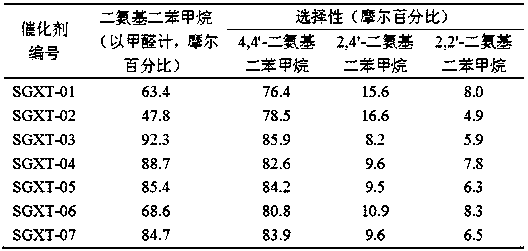

[0024] Prepare a mixed solution of inorganic strong acid and dichromate or chromate, and take 200mL of the mixed solution and 50g of activated carbon, and place them in a 500mL three-necked flask. Place the three-neck flask in a magnetic stirring heating mantle, heat and reflux at a certain temperature for a certain period of time, take out the modified activated carbon, filter, wash until neutral, and dry it in a vacuum oven at 105°C to constant weight to obtain the acid-modified Activated carbon, numbered uniformly and placed in a desiccator for later use. The acid-modified activated carbons prepared under different conditions are shown in Table 1.

[0025] Table 1 Acid-modified activated carbon prepared under different conditions

[0026]

Embodiment 2

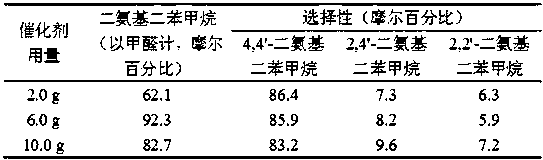

[0028] Place 6.0g of acid-modified activated carbon SGXT-01, SGXT-02, SGXT-03, SGXT-04, SGXT-05, SGXT-06, SGXT-07, and 168.3g of freshly distilled aniline in a 250mL reactor, Fully replace the air in the kettle. Add 48.9 g of 37% formaldehyde aqueous solution into the kettle dropwise through a metering pump, and stir thoroughly for 30 minutes after the addition is completed, during which the temperature is controlled at 30-50°C. After completing the above operations, set the reaction temperature to 120° C. and the reaction time to 6 hours to carry out the reaction. After the reaction is completed, the catalyst and the reaction product are separated through a sand core funnel, and the catalyst is recycled. The reaction product was purified by vacuum distillation, the unreacted aniline was recycled, and the bottom product was analyzed by liquid chromatography. The results are shown in Table 2.

[0029] Product liquid chromatography analysis under different catalysts in table 2...

Embodiment 3

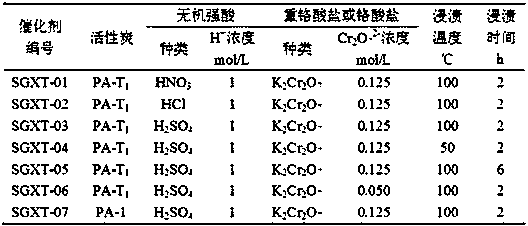

[0032] Put 6.0g of acid-modified activated carbon SGXT-03 and 168.3g of freshly distilled aniline in a 250mL reaction kettle, and fully replace the air in the kettle with nitrogen. Add 48.9 g of 37% formaldehyde aqueous solution into the kettle dropwise through a metering pump, and stir thoroughly for 30 minutes after the addition is completed, during which the temperature is controlled at 30-50°C. After completing the above operations, set the reaction temperature to 80°C, 120°C, and 160°C respectively, and the reaction time to 6h to carry out the reaction. After the reaction is completed, the catalyst and the reaction product are separated through a sand core funnel, and the catalyst is recycled. The reaction product was purified by vacuum rectification, the unreacted aniline was recycled, and the bottom product was analyzed by liquid chromatography. The results are shown in Table 3.

[0033] Product liquid chromatography analysis under table 3 different reaction temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com