Water inlet structure vortex control device based on fermat's spiral

A Fermat spiral and water inlet technology, which is applied to water supply devices, drainage structures, waterway systems, etc., can solve problems such as reducing the energy performance and cavitation performance of water pumps, affecting the safety and reliability of water pumps, and failing to work safely and stably. Easy to promote and implement, save materials, and ensure economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

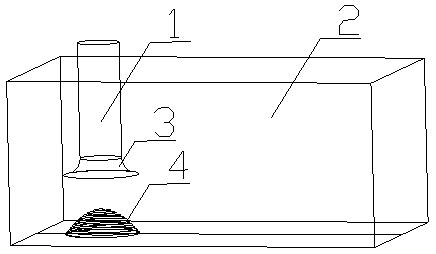

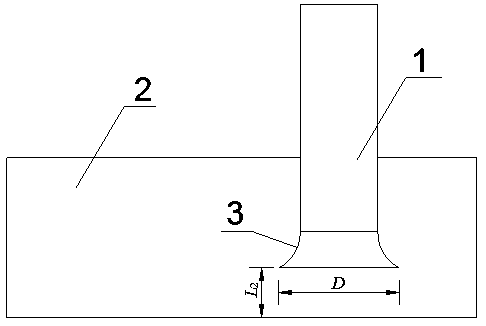

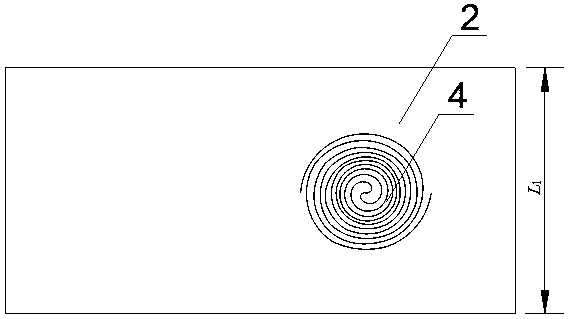

[0023] The present invention will be further described below in conjunction with the accompanying drawings and description of the accompanying drawings. In the figure, L 1 is the width of the inlet structure 2, D Be the trumpet mouth diameter of horn pipe 3, L 2 is the suspension height of the trumpet tube 3;

[0024] A water inlet structure vortex control device based on Fermat's spiral, comprising a vortex control device 4 arranged in the water inlet structure 2, a water suction pipe 1 and a trumpet pipe 3 connected with the water suction pipe 1 are arranged on the vortex control device 4, and The trumpet tube 3 is placed in the water inlet structure 2; when the vortex control device 4 is made, the following steps are included:

[0025] Step 1), take the width of the water inlet structure 2 L 1 and the horn mouth diameter of the horn tube 3 D As a constraint condition, the Fermat spiral equation is used to design the vortex control device, and the projection point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com