Wall brick capable of building wall rapidly

A technology for laying wall bricks and laying walls, applied in the field of wall laying bricks, can solve the problems of size error, waste and slow efficiency of splicing, and achieve the effect of reducing air bubbles and reducing the probability of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

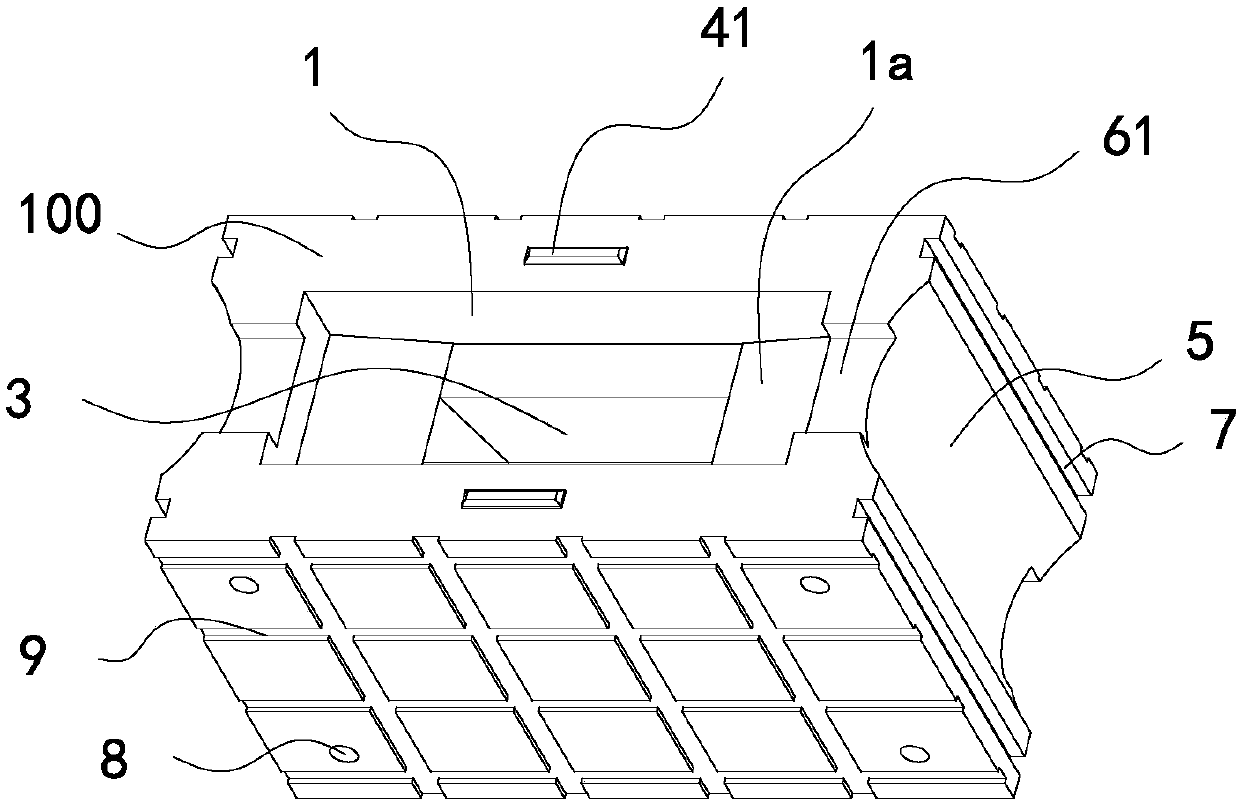

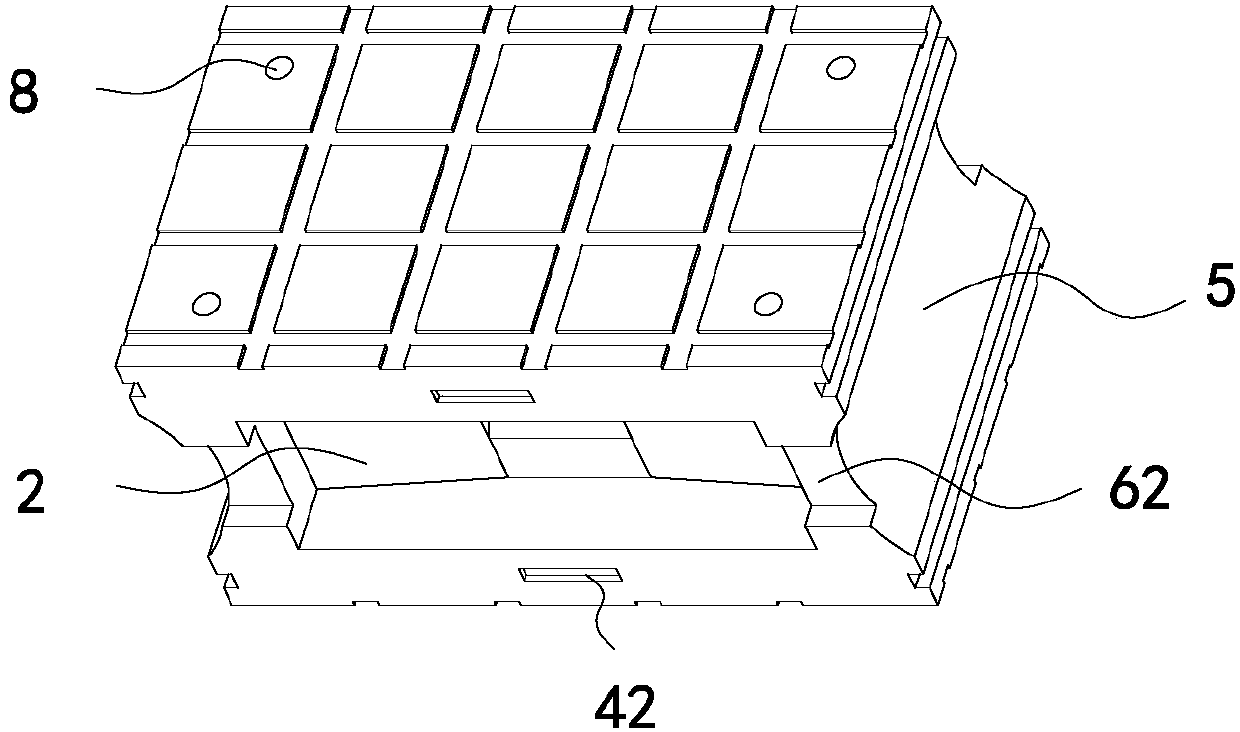

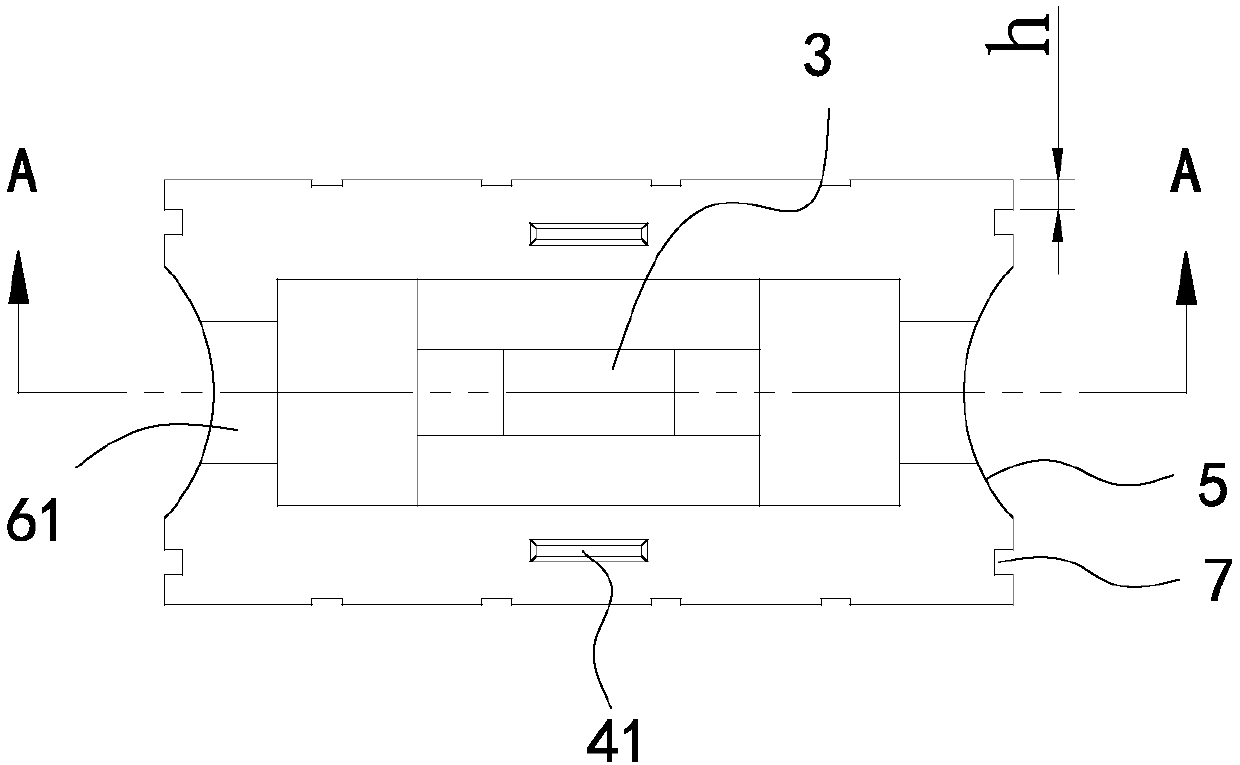

[0029] Such as Figure 1 to Figure 6 As shown, a wall brick that can be quickly built in this embodiment includes a brick body 100, the brick body 100 is a cube, the top surface of the brick body 100 is provided with a top groove 1, and the brick body The bottom surface of 100 is provided with a bottom groove 2, the projected area of the top groove 1 and the bottom groove 2 overlaps, and a through internal grouting channel 3 is provided between the top groove 1 and the bottom groove 2, and the internal grouting At least one inner wall of the channel 3 is inclined, and the cross-sectional area of the inner grouting channel 3 decreases gradually from top to bottom.

[0030] The internal grouting channel 3 includes a left inner wall, a right inner wall, a front inner wall, and a rear inner wall. The left inner wall and the right inner wall are all inclined. It should be noted that the front, rear, and left , right are based on figure 1 The direction of placement in is for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com