Wall surface processing device

A treatment device and adjustment device technology, which is applied in the direction of construction and building construction, can solve the problems of large waste, difficulty in realizing intelligent operation, and difficulty in ensuring uniform paint distribution, so as to achieve the goal of reducing waste, reducing processing difficulty, and perfect processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

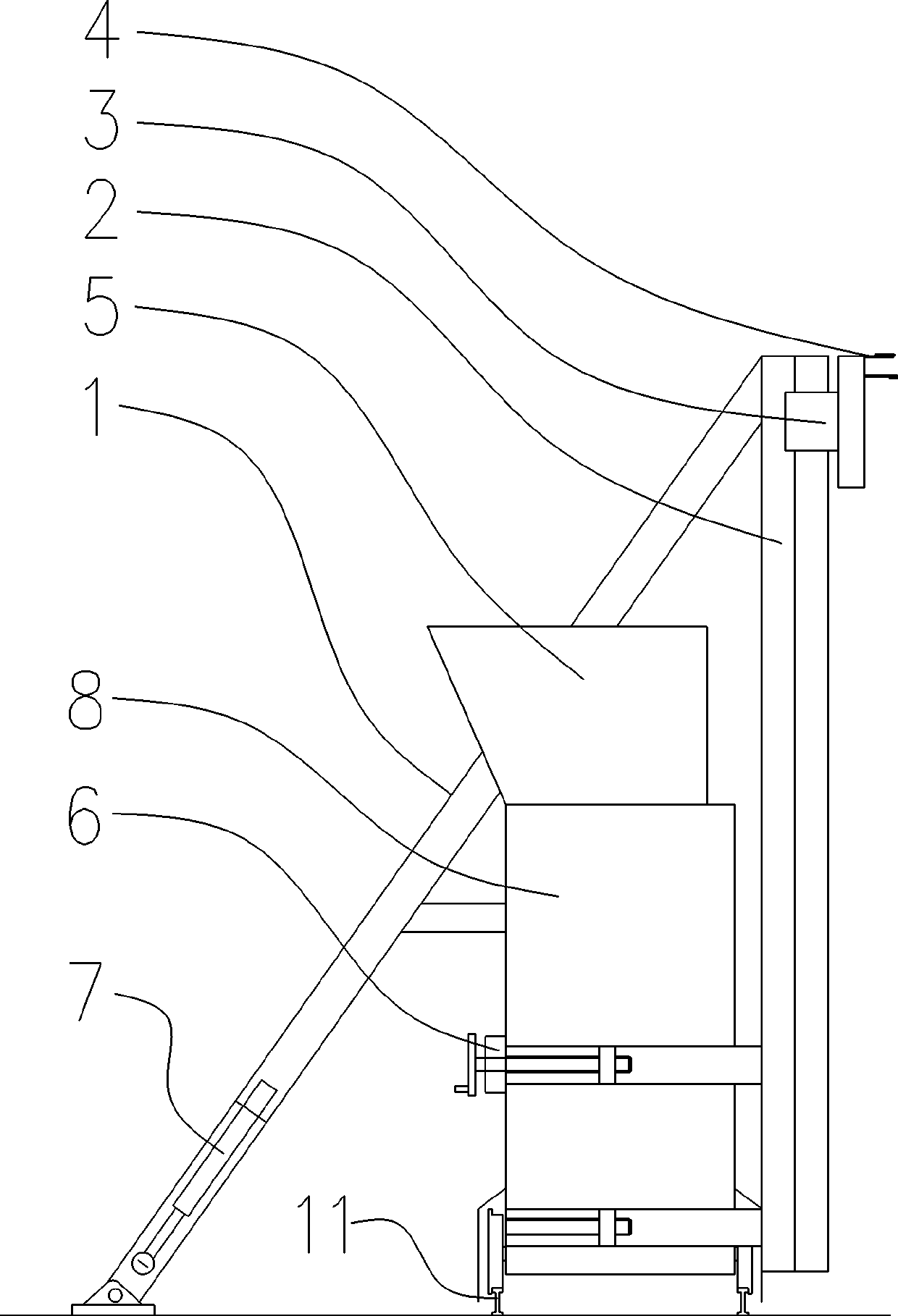

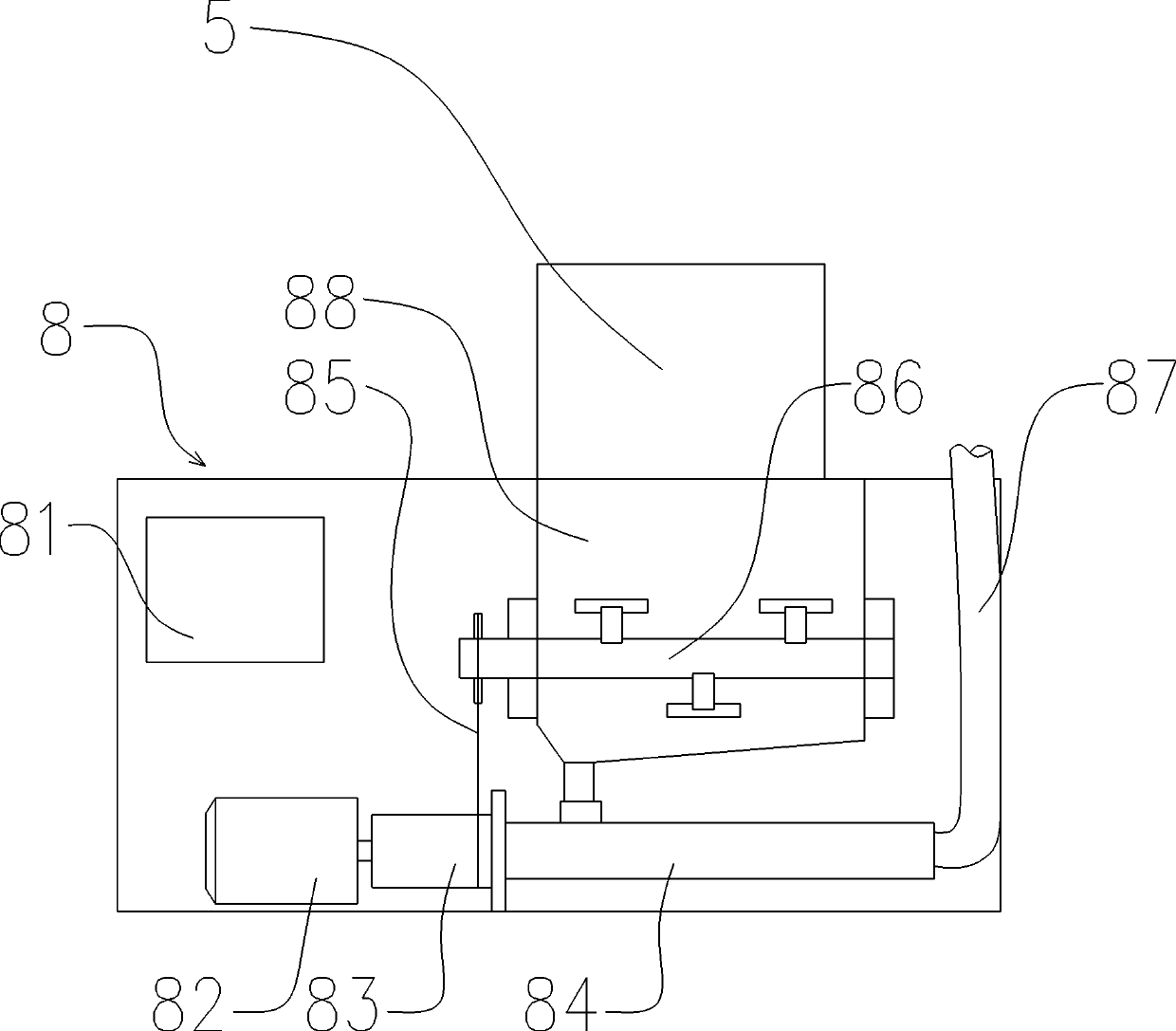

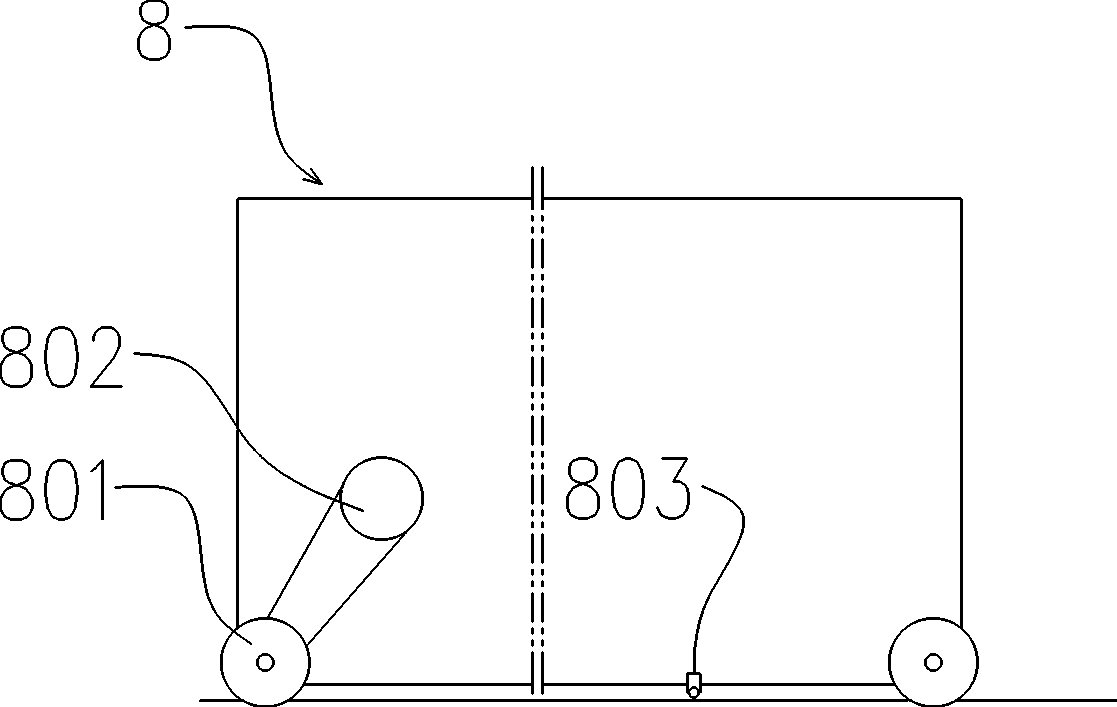

[0031] Such as Figure 1~4 Among them, a wall surface treatment device, which includes a car body 8 that walks along the track 11, and a walking drive device is arranged in the car body 8; 802 is connected with driving wheel 801, and a displacement detection device 803 is also provided at the bottom of vehicle body 8. The displacement detection device 803 in this example adopts a photoelectric displacement detection device, which is used to accurately detect the distance traveled by the car body 8 along the track 11, so as to ensure that the width of the paint 10 coated on each column is consistent during construction. In a preferred solution, a control device 81 is also provided, and the control device 81 is electrically connected with the traveling drive device, the first lifting drive device and the slurry supply device.

[0032] The control device 81 is preferably arranged in the car body 8. The control device 81 in this example adopts PLC, and the PLC controls the walkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com