Bypass valve actuator for turbocharger

A turbocharger and actuator technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of vehicle false alarms, failure to maximize potential, false alarms, etc., to eliminate shocks, facilitate debugging and The effect of maintenance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

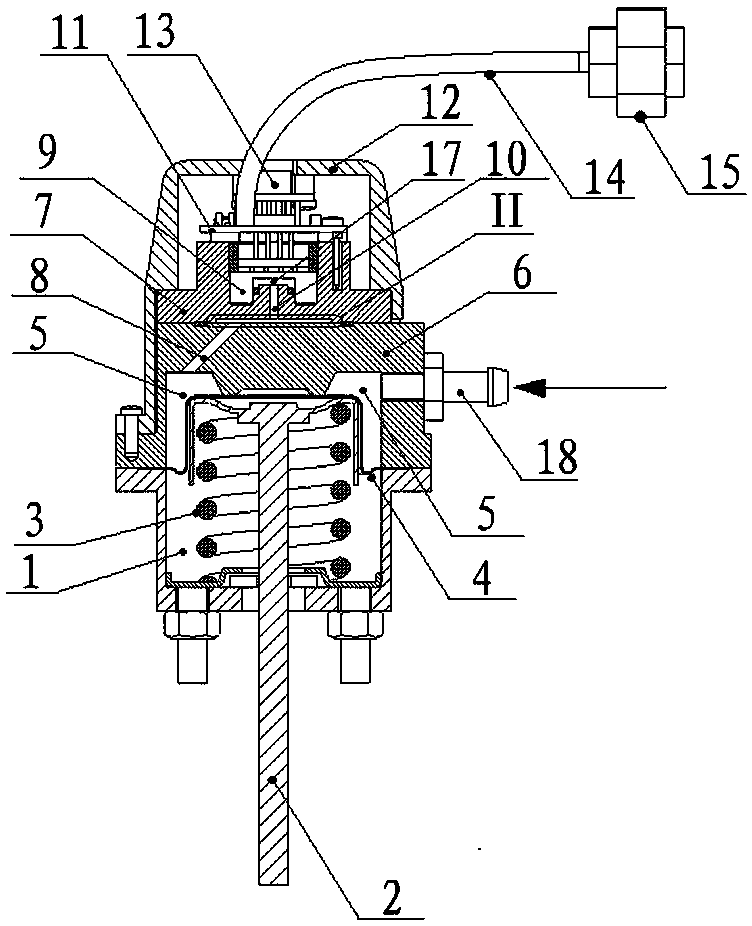

[0030] Combine below Figure 1~Figure 6 This program will be further described with specific examples.

[0031] Such as Figure 1~Figure 6 As shown, this embodiment relates to a turbocharger bypass valve actuator, which includes a push rod chamber 1, an actuator push rod 2 that passes through the push rod chamber 1, and is located in the push rod chamber 1 and sleeved on the actuator. The spring 3 on one end of the push rod 2; the upper part of the push rod chamber 1 is provided with at least 2 sealed cavities, and each of the sealed cavities is connected through a connecting channel in turn, and an air inlet nozzle is provided on one of the sealed cavities 18.

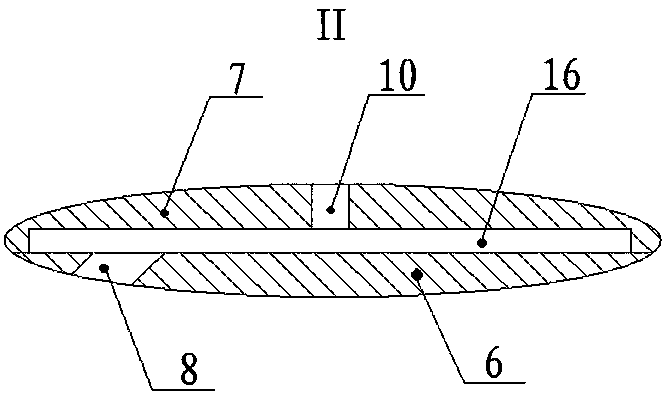

[0032] Further, when the number of the sealed cavities is equal to 2, the number of the connecting channels is equal to 1, which is used as the first connecting channel 8; the two sealed cavities are respectively the first sealed cavity 5 and the second sealed cavity 16, the first sealed cavity 5 and the second sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com