Large-flow gradual type gapless automatic limiting pilot valve for hydraulic device

A hydraulic device and automatic limit technology, applied in the field of hydraulic devices, can solve the problems of few functions, time-consuming and laborious operation, low pressure, etc., and achieve the effects of easy and labor-saving operation, good functional diversity and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

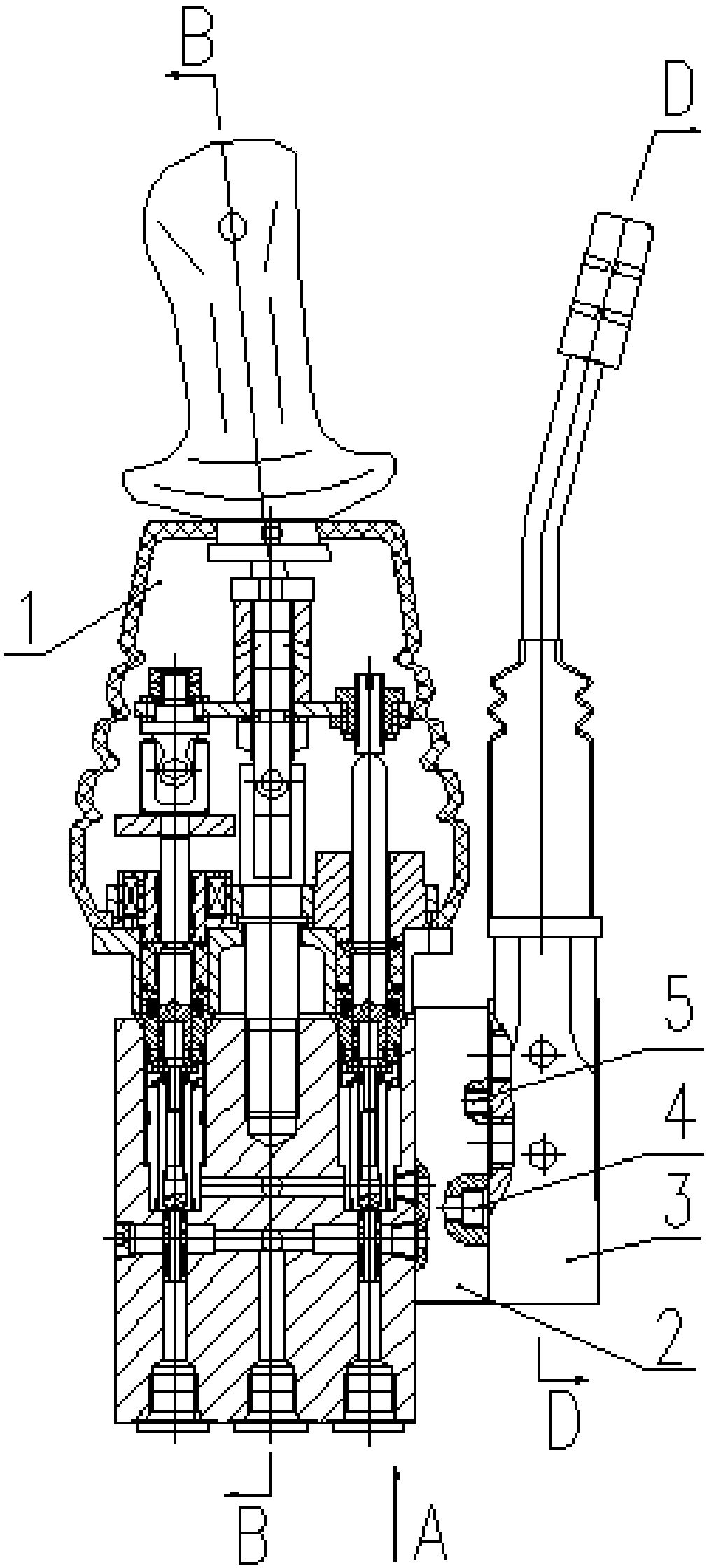

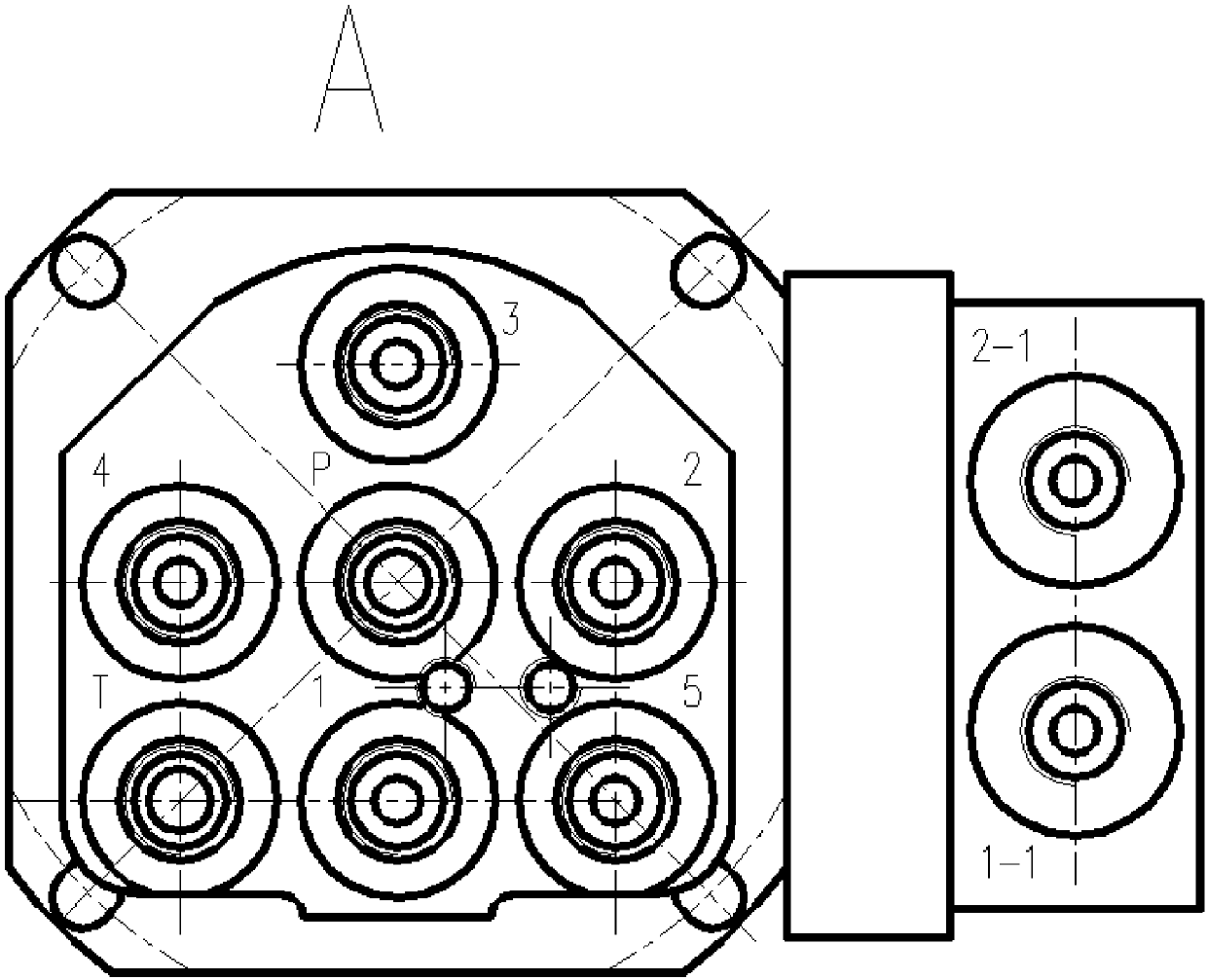

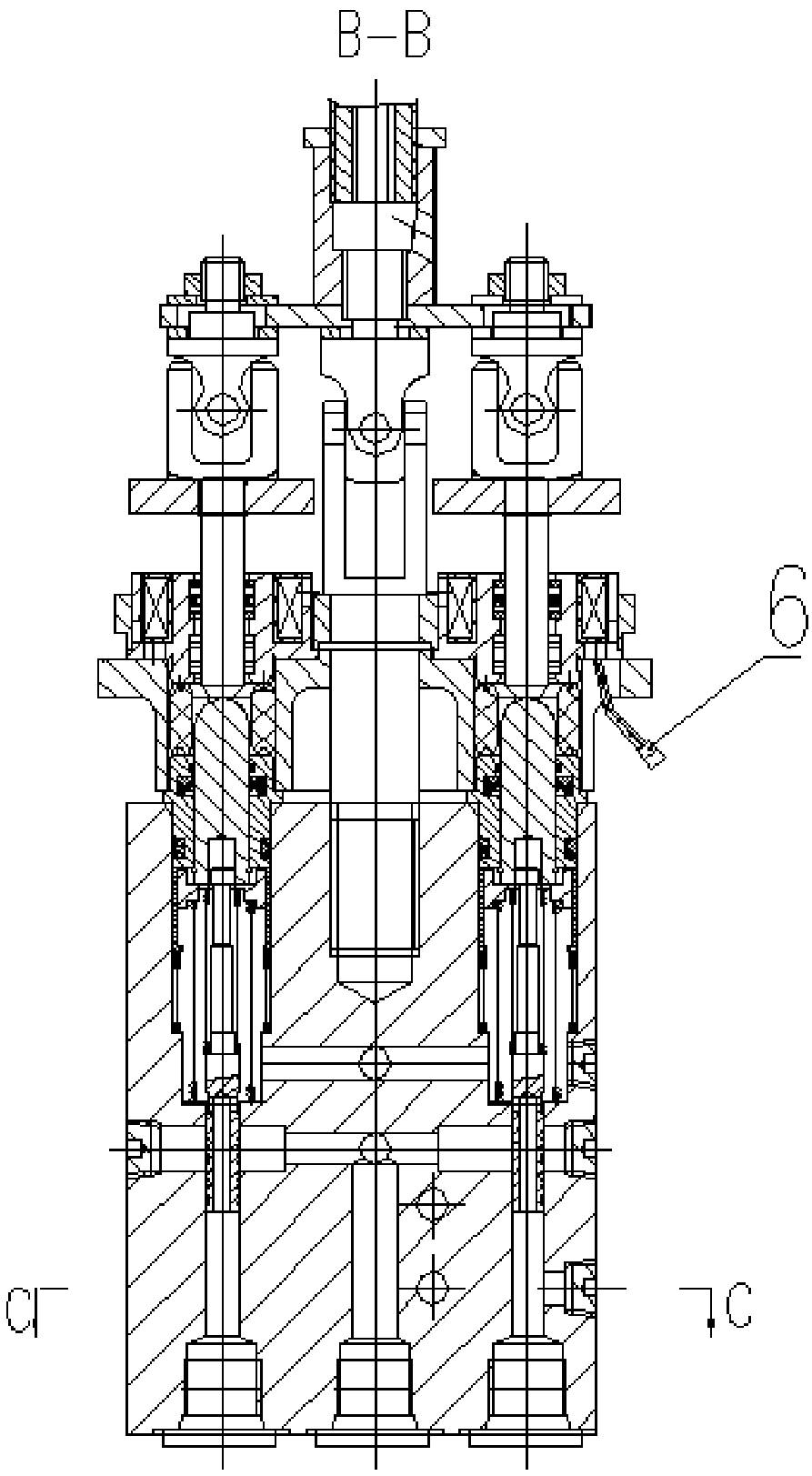

[0023] A large-flow progressive gapless automatic limit pilot valve for hydraulic devices. The pilot valve is composed of three parts: No. 1 valve 1, connecting plate 2, and No. 2 valve 3. The connecting plate 2 connects with The No. 1 valve 1 is connected, the No. 2 valve 3 is connected with the connection plate 2 through the second screw 5, and the No. 1 valve 1 is also equipped with an electromagnetic interface 6; the bottom of the No. 1 valve 1 is distributed with 7 oil passage interfaces in the shape of "you" , where the middle of the word "you" is the oil inlet port P, the left side of the bottom is the stop port T port, and the right side of the bottom is the additional stop port 5 port. The electromagnetic interface 6 in the No. 1 valve is connected to the built-in valve mechanism of the No. 1 valve; The bottom of No. 3 valve 3 is provided with two holes whose circle centers are parallel to ports 1-1 and 1-2 on the matching surface of connecting plate 2 and No. 2 valve ...

Embodiment 2

[0025] The whole is consistent with Example 1, the difference is:

[0026] Wherein the tightening torque of the first screw 4 is 12Nm; the tightening torque of the second screw 5 is 31Nm.

[0027] When using this embodiment, compared with Embodiment 1, the stability of the present invention will be slightly reduced, but it is still significantly better than the prior art.

Embodiment 3

[0029] The whole is consistent with Example 1, the difference is:

[0030] The tightening torque of the first screw 4 is 16Nm; the tightening torque of the second screw 5 is 39Nm.

[0031] When this embodiment is used, compared with Embodiment 1, the service life of the present invention will be slightly reduced, but it is still significantly better than the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com