Extractor hood filter net structure and extractor hood

A range hood and filter technology, which is applied in the field of range hood filter structure, can solve the problems of bacterial odor, single method of oil filtration and interception, and affect the performance of the range hood, so as to achieve the effect of reducing oil fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

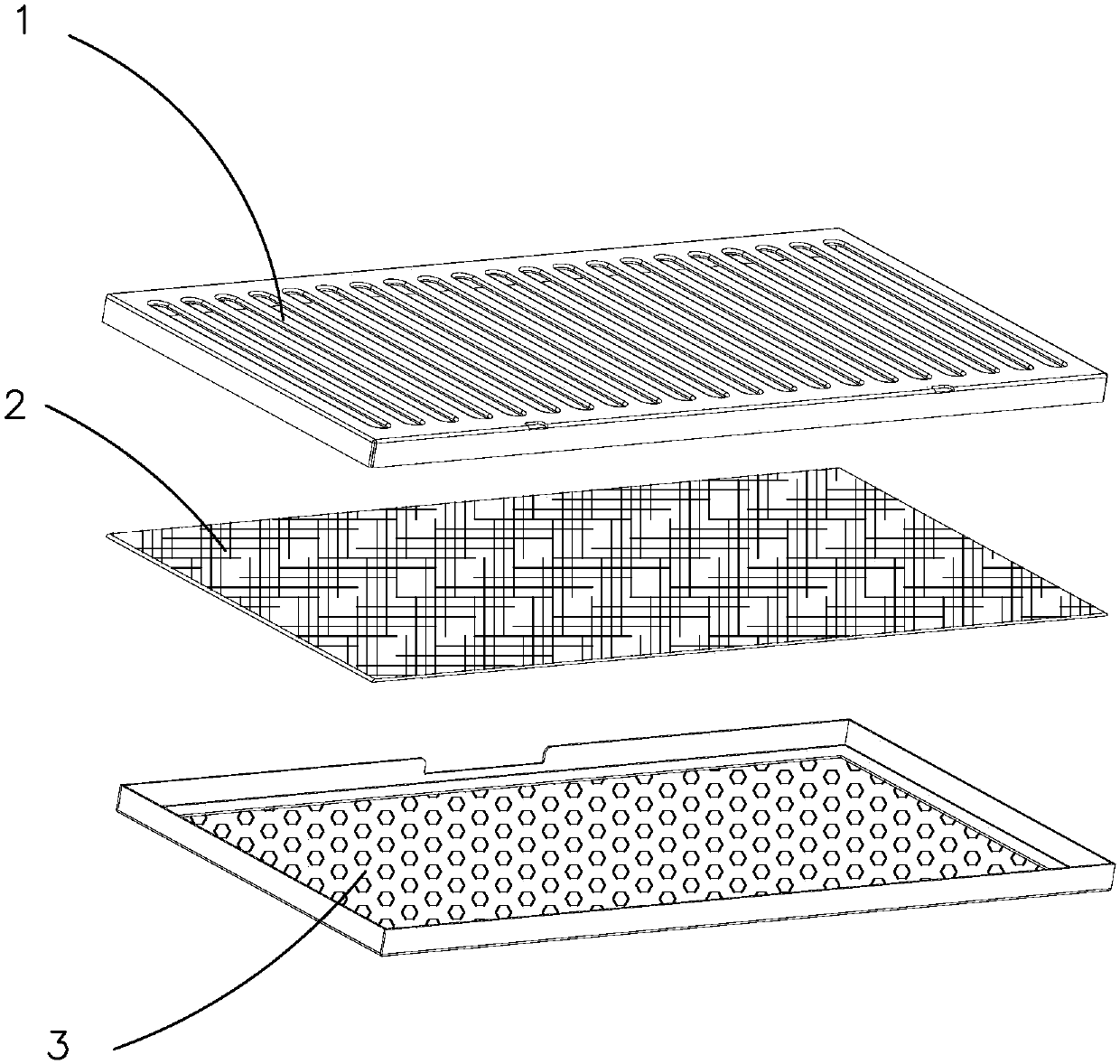

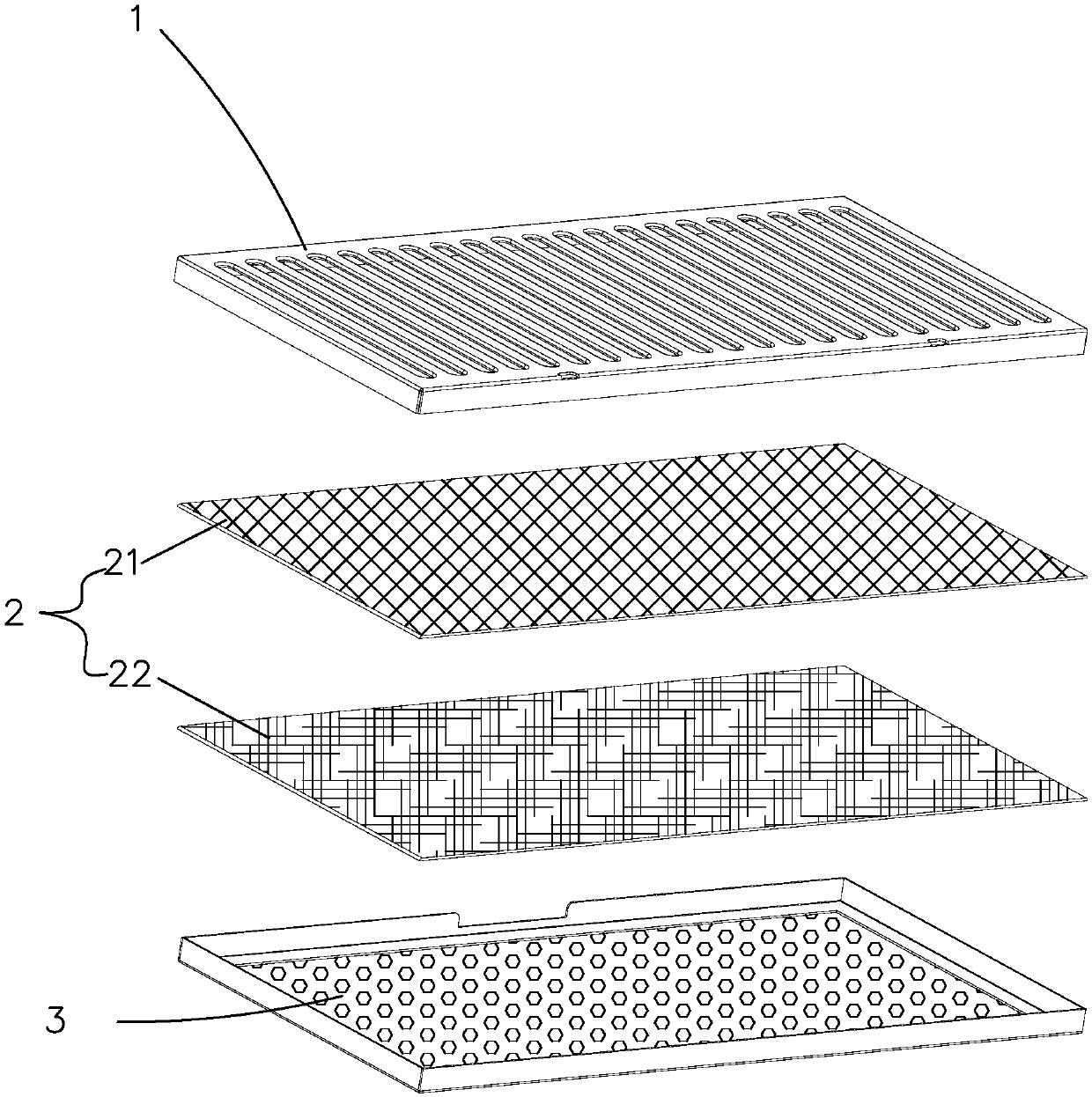

[0026] Such as Figure 1 to Figure 3 As shown, a filter screen structure for range hoods includes a first layer of filter screen 1, a second layer of filter screen 2 and a third layer of filter screen 3 arranged in sequence, the first layer of filter screen 1 and the third layer of filter screen The filter screen 3 is a sheet metal screen with through holes, and the second filter screen 2 includes a filter sponge 22 .

[0027] The first layer of filter screen plays the role of the first oil fume blocking and interception, and pre-treats the oil fume;

[0028] The second layer of filter has good air flow characteristics, low wind resistance and strong adsorption capacity, not only has little effect on air volume and wind pressure, but also fully absorbs the grease in the oil fume, which greatly improves the oil interception efficiency of the filter; I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com