Multistage high-position heat extraction and high-efficiency waste heat evaporation and heat absorption combined heating and water heating integrated machine and operation method thereof

An evaporative and heat-absorbing, combined technology is applied in the field of multi-level high-level heat extraction and high-efficiency waste heat evaporating and heat-absorbing combined heating and hot water all-in-one machine, which can solve the problems of inability to promote the market, cumbersome installation, and inability to install and use. Save labor installation costs, increase heat absorption area, and achieve reliable return air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

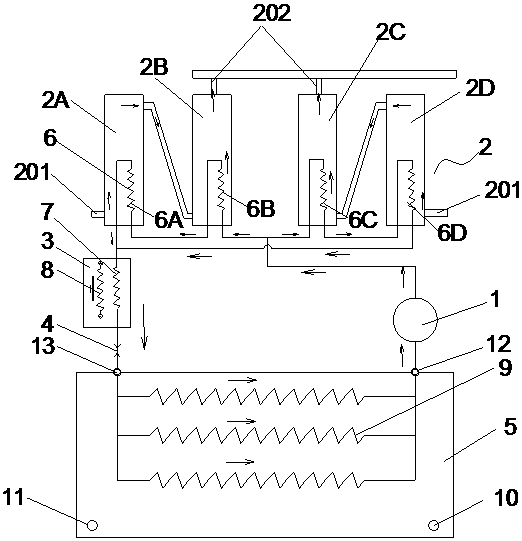

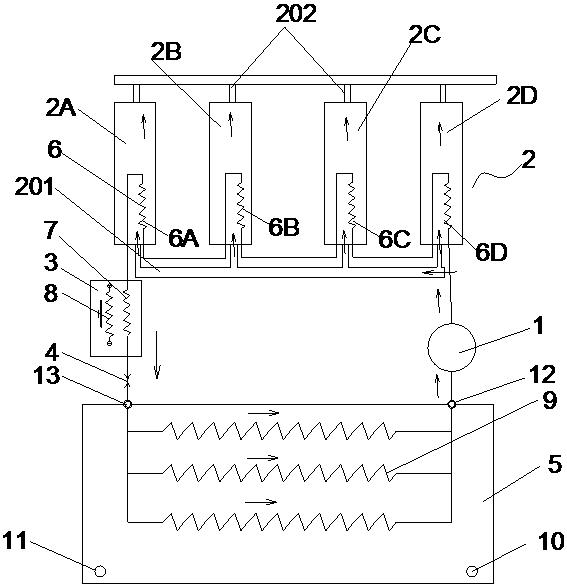

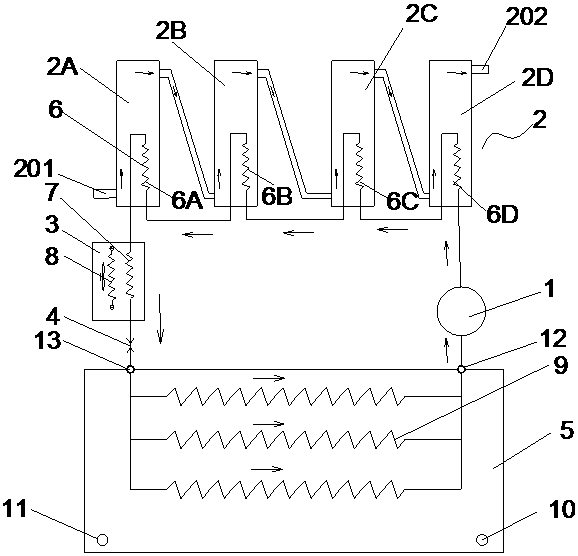

[0023] The multi-stage high-level heat extraction and high-efficiency waste heat evaporation and heat absorption combined heating and hot water integrated machine of the present invention includes a heat pump compressor 1, a multi-stage series-parallel water tank 2, a heater tank 3, a throttle valve 4 and a device connected in sequence. The waste heat accumulator 5 of the evaporator, the multi-stage series-parallel water tank 2 has a unified tap water inlet 201 and the hot water outlet 202, and a plurality of water tank condensers 6 are arranged in the multi-stage series-parallel water tank 2, and the heater tank 3 is provided with a heating condenser 7 and an electric auxiliary heater 8 for auxiliary heating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com