Low-cost solar thermal power generation sensible heat-latent heat composite heat storage ceramic and preparation method thereof

A solar thermal power generation, low-cost technology, applied in solar thermal power generation, solar thermal storage, solar thermal energy and other directions, can solve the problems of phase change material leakage, strong corrosion and low thermal conductivity of heat storage tanks, and improve thermal conductivity. performance, improve thermal shock resistance, and improve the effect of heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

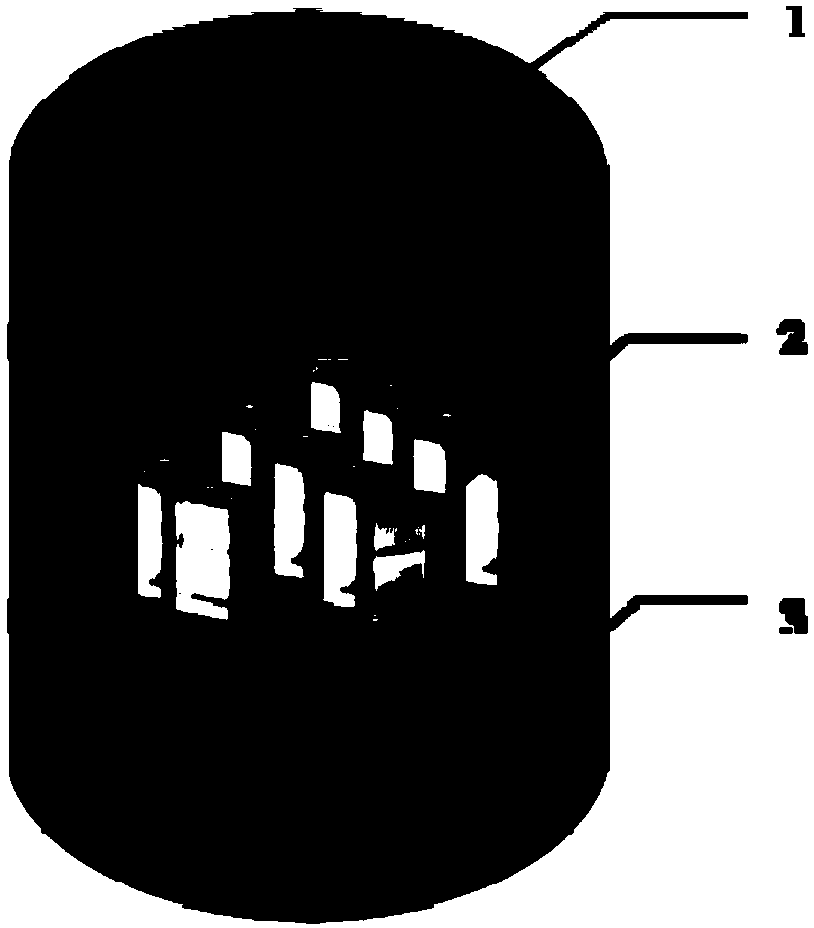

[0033] A low-cost solar thermal power generation sensible heat-latent heat composite heat storage ceramics (see attached figure 1 ), the preparation steps are as follows:

[0034] 1) Raw material treatment: ball mill the coal-series kaolin and aluminum powder for 1 hour respectively, and pass through a 250-mesh sieve.

[0035] 2) Raw material ratio: the mass percentage of each raw material is: 65% of coal series kaolin and 35% of aluminum powder.

[0036] 3) Mixing of raw materials: Coal-based kaolin and aluminum powder are mixed in a kneader for 2 hours to obtain a mixture; add binder, lubricant and water to the mixture and mix for 20 minutes, then use a vacuum mud mixer to refine the mud and age it for 24 hours. Get stale good mud.

[0037] The binding agent is a mixture of carboxymethyl cellulose and polyvinyl alcohol in a mass ratio of 1:1, and the addition is 3% of the weight of the mixture; the lubricant is tung oil, and the addition is 4% of the weight of the mixture;...

Embodiment 2

[0048] A low-cost solar thermal power generation sensible heat-latent heat composite heat storage ceramic, the preparation steps are as follows:

[0049] 1) Raw material treatment: ball mill the coal series kaolin and aluminum powder for 2 hours respectively, and pass through a 325-mesh sieve.

[0050] 2) Raw material ratio: the mass percentage of each raw material is: 70% of coal series kaolin and 30% of aluminum powder.

[0051] 3) Mixing of raw materials: Coal-based kaolin and aluminum powder are mixed in a kneader for 2 hours to obtain a mixture; binder, lubricant and water are added to the mixture and mixed for 30 minutes, and then the mud is refined with a vacuum mud mixer and aged for 30 hours. Get stale good mud.

[0052] The binding agent is a mixture of polyvinyl alcohol and water glass in a mass ratio of 1:1, and the add-on is 5% of the weight of the mix; the lubricant is soybean oil, and the add-on is 5% of the weight of the mix; the add-on of water is 20% by wei...

Embodiment 3

[0061] A low-cost solar thermal power generation sensible heat-latent heat composite heat storage ceramic, the preparation steps are as follows:

[0062] 1) Raw material treatment: ball mill coal series kaolin and aluminum powder for 2 hours respectively, and pass through a 250-mesh sieve.

[0063] 2) Raw material ratio: the mass percentage of each raw material is: 68% of coal series kaolin and 32% of aluminum powder.

[0064] 3) Mixing of raw materials: Mix coal-based kaolin and aluminum powder in a kneader for 1 hour to obtain a mixture; add binder, lubricant and water to the mixture and mix for 20 minutes. Get stale good mud.

[0065] The binding agent is polyvinyl alcohol, and the addition is 5% of the mixture weight; the lubricant is a mixture of tung oil and soybean oil in a mass ratio of 1:1, and the addition is 4% of the mixture weight; the addition of water is 22% by weight of the mix.

[0066] 4) Honeycomb body molding: Extrude the stale mud material through an ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Heat storage density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap