Continuous distributed optical fiber temperature monitoring system

A distributed optical fiber and monitoring system technology, applied in the field of temperature measurement, can solve the problems of high temperature point distance and temperature measurement accuracy, difficulty in determining over-limit points, and complicated lines, so as to achieve more temperature measurement points, reduce external interference, and reduce line complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

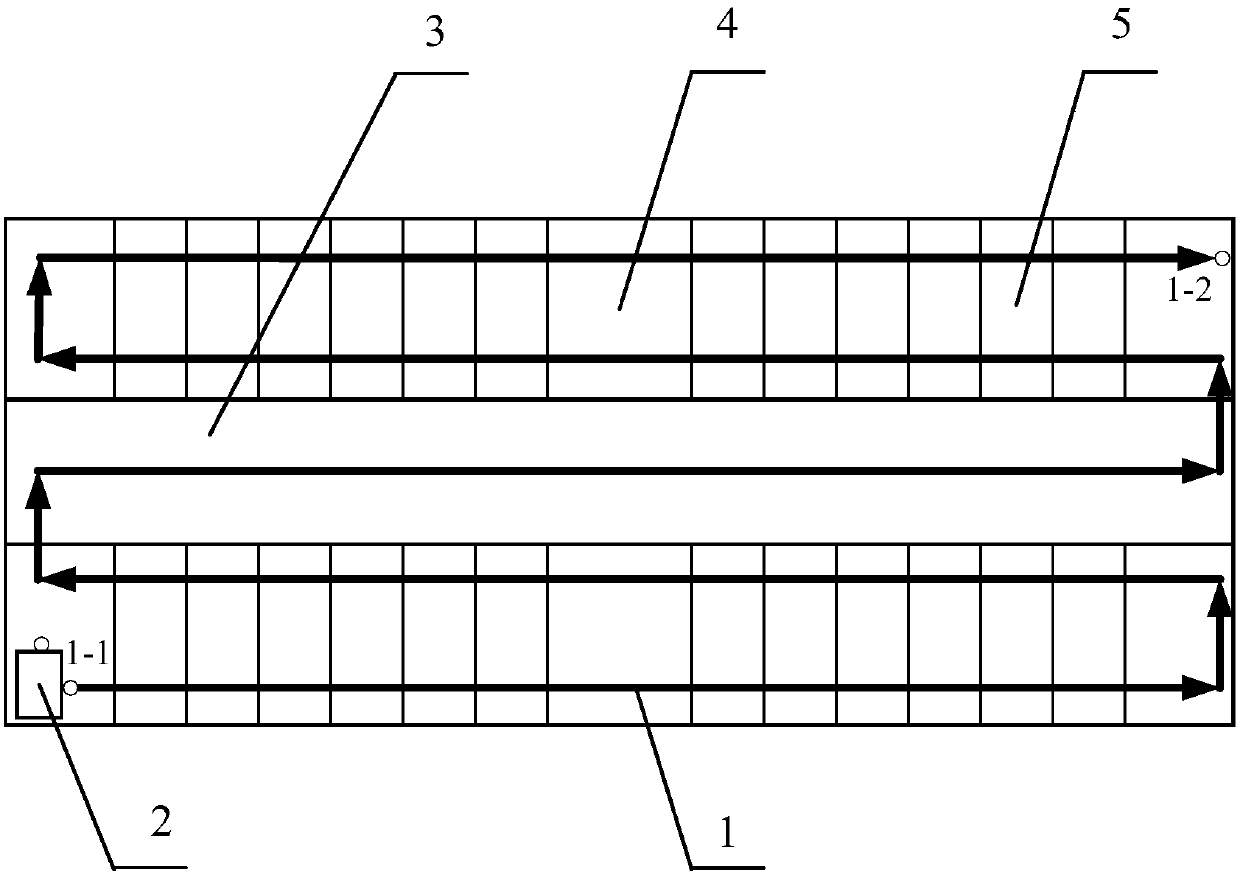

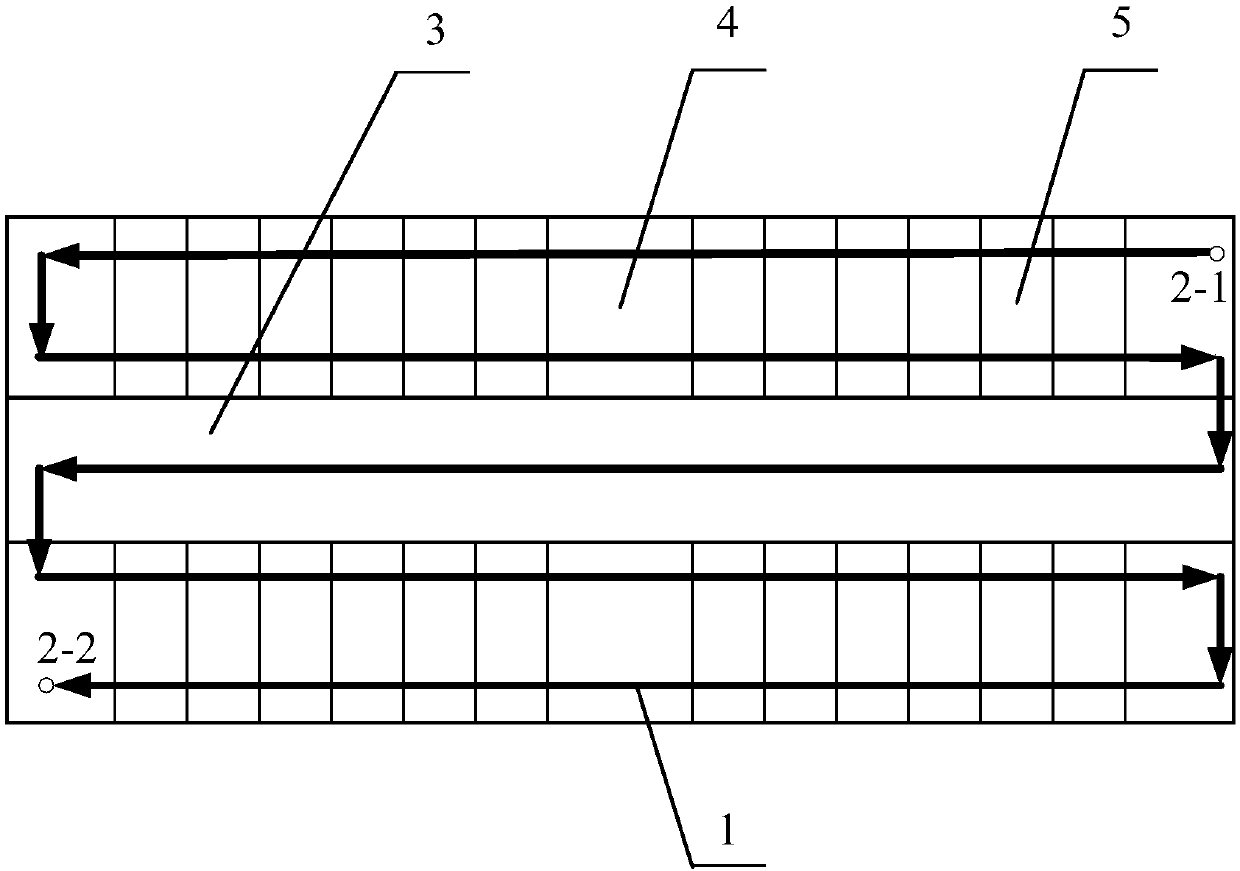

[0037] See figure 1 , Figure 7 , taking fiber optic monitoring of the temperature of a building as an example:

[0038] The continuous distributed optical fiber temperature monitoring system includes a temperature detector 2 and a temperature measuring optical fiber 1. The temperature measuring optical fiber 1 is one piece, which is continuously arranged at all positions to be monitored. The temperature measuring optical fiber 1 is connected to the temperature detector 2; The detector 2 includes a controller, a signal generator, a fiber laser, a preamplifier, a lock-in amplifier, a data acquisition card, an all-solid-state computer, and a GPRS / LTE module; 1 One end is connected to the fiber laser, and the other end is connected to the preampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com