A Modeling and Compensation Method for Spindle Radial Thermal Drift Error of Horizontal CNC Lathe

A technology of numerical control lathe and compensation method, which is applied in the direction of simulator, program control, computer control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107]In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific implementations of the testing, modeling and compensation of spindle radial thermal drift errors and with reference to the accompanying drawings. This embodiment provides detailed implementation and specific operation process on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

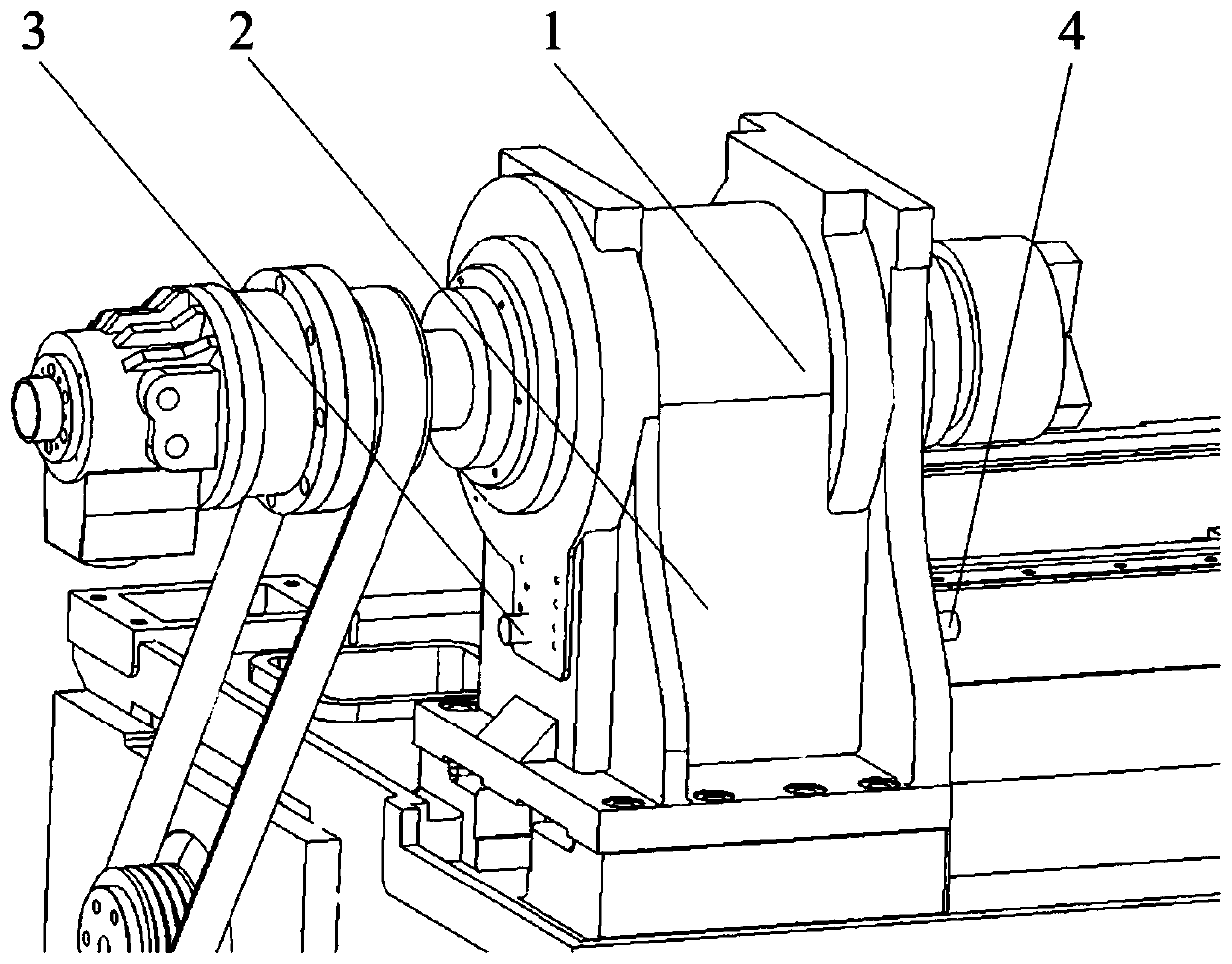

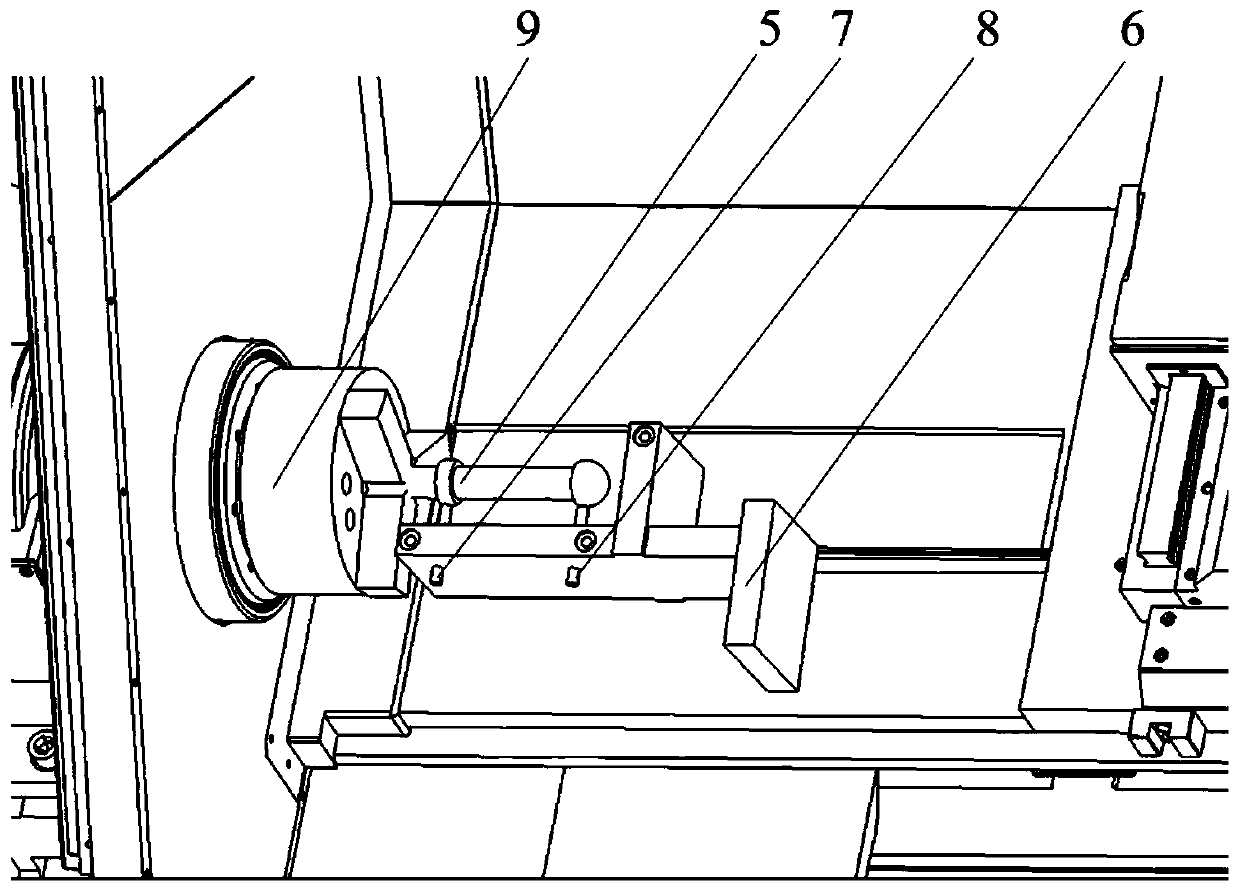

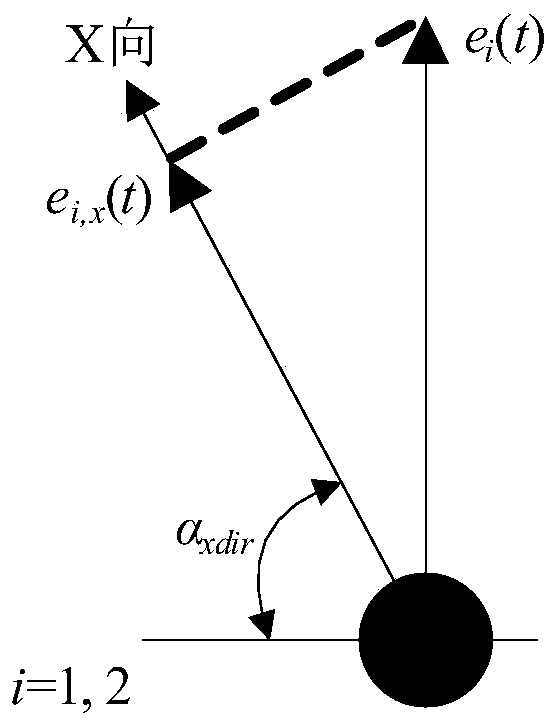

[0108] The inclination angle of the X-axis saddle of the horizontal CNC lathe is 60°, the mechanical spindle 1 is installed horizontally on the bed, and is driven by a belt with a maximum speed of 5000rpm. The distance between the two sides of the spindle box 2 is 356mm. During the test, the distance from the right side of the spindle box 2 to the left displacement sensor 7 is 251mm, and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com