Silicon controlled rectifier (SCR) for ESD (Electro Static Discharge) protection

A silicon rectifier and low-trigger technology, applied in the direction of diodes, etc., can solve the problems of increasing power consumption, reducing the advantages of SCR strong ESD robustness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

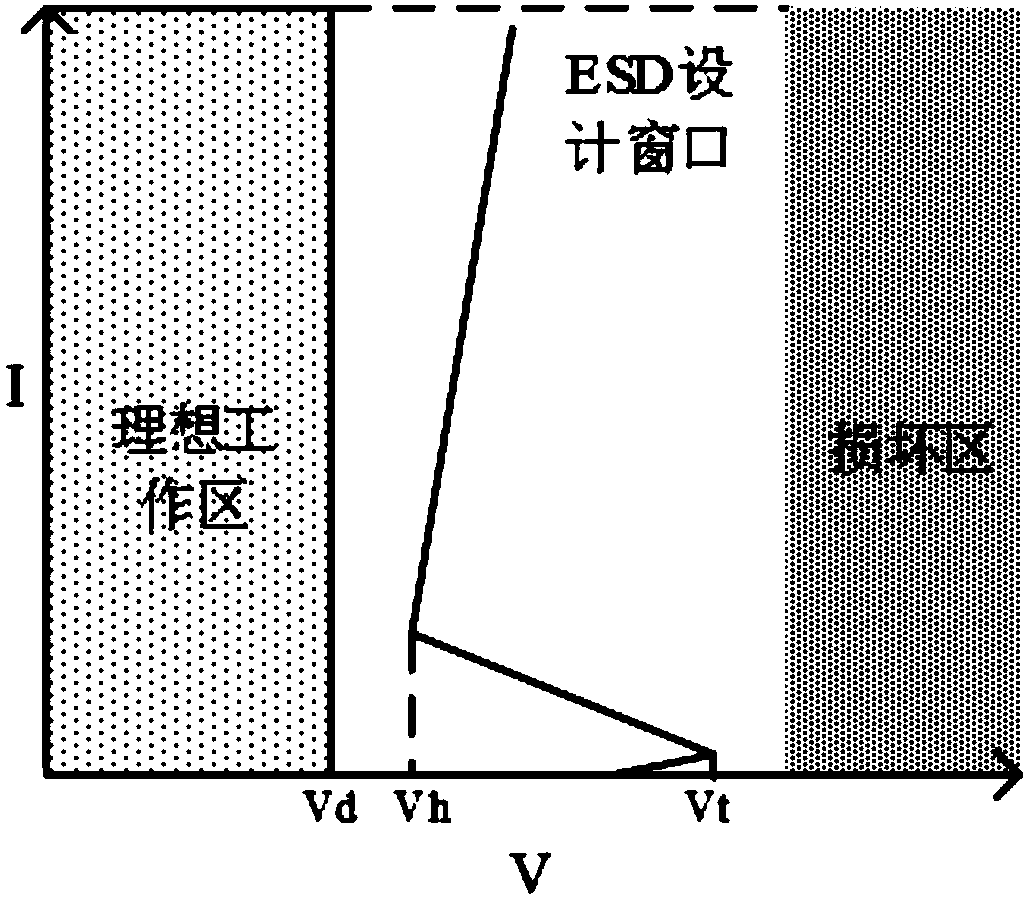

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

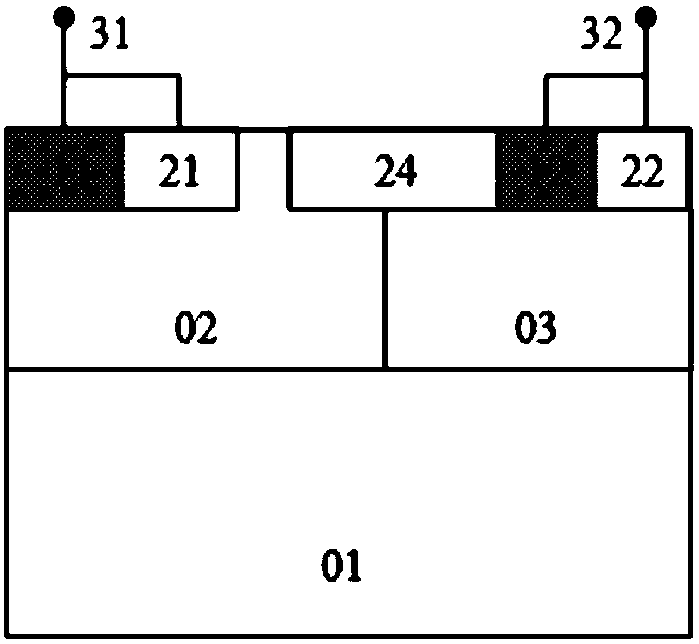

[0029] Such as figure 2 As shown, a silicon controlled rectifier for ESD protection includes: p-type substrate 01, nwell region 02 implanted on the p-type substrate, pwell region 03 tangent to the right edge of nwell region 02, and nwell region 03 The first N+ contact region 11 implanted on the surface of region 02, the first P+ region 21 tangent to the right edge of the first N+ contact region 11; the first N+ contact region 11 and the first P+ region 21 constitute an N+P+ region unit, The first N+ contact region 11 and the surface of the first P+ region 21 are short-circuited with metal to form the device anode 31; it also includes the second P+ region 22 implanted on the surface of the pwell region 03 and tangent to its right edge, and the second P+ region 22 The second N+ contact region 12 whose left edge is tangent, the adjacent second P+ region 22 and the second N+ contact region 12 form a P+N+ region unit, and the second N+ contact region 12 and the second P+ region 22...

Embodiment 2

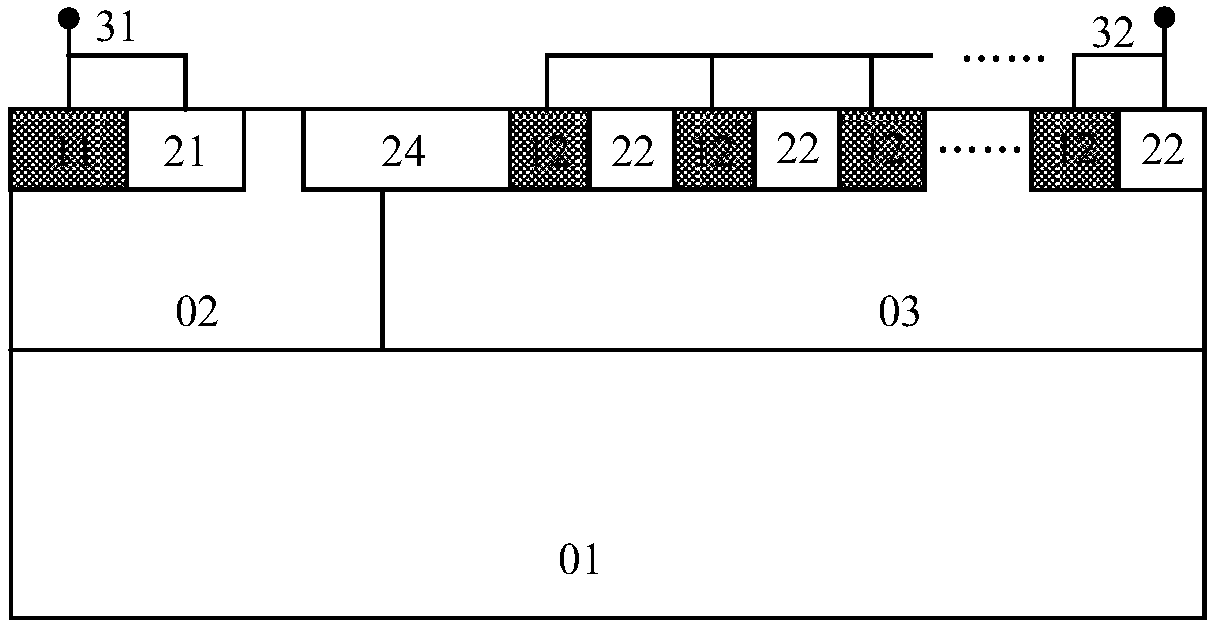

[0045] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: more than one P+N+ region unit is included in the pwell region 03 . The N+ area in any one of the P+N+ area units is tangent to the P+ area, and the two adjacent P+N+ area units are tangent; the second N+ contact area 12 and the rightmost The second P+ region 22 on the side is connected to form the cathode 32 of the device. By adding N+ / P+ repeating units, the vertical emission capability of the npn tube can be changed.

Embodiment 3

[0047] Such as Figure 4 As shown, the silicon controlled rectifier used for ESD protection in this embodiment includes a p-type substrate 01, an nwell region 02 formed by implantation on the p-type substrate, a pwell region 03 tangent to the right edge of the nwell region 02, The second P+ region 22 implanted on the surface of the pwell region 03 tangent to its right edge, the second N+ contact region 12 tangential to the left edge of the second P+ region 22, the adjacent second P+ region 22 and the second N+ contact The region 12 constitutes a P+N+ region unit, and the second N+ contact region 12 and the second P+ region 22 are connected to form a device cathode 32;

[0048] The first N+ contact region 11 implanted on the surface of the nwell region 02 is tangent to its left edge, the first P+ region 21 is tangent to the right edge of the first N+ contact region 11, the adjacent first N+ contact region 11 and the first The P+ area 21 constitutes an N+P+ area unit, and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com