Latch-free SCR for ESD protection

A latch and substrate technology, applied in the field of latch-free SCR, can solve the problems of reduced secondary breakdown current, increased power consumption, logic errors, etc., to achieve lower trigger voltage, better ESD protection, and anti-Latch-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

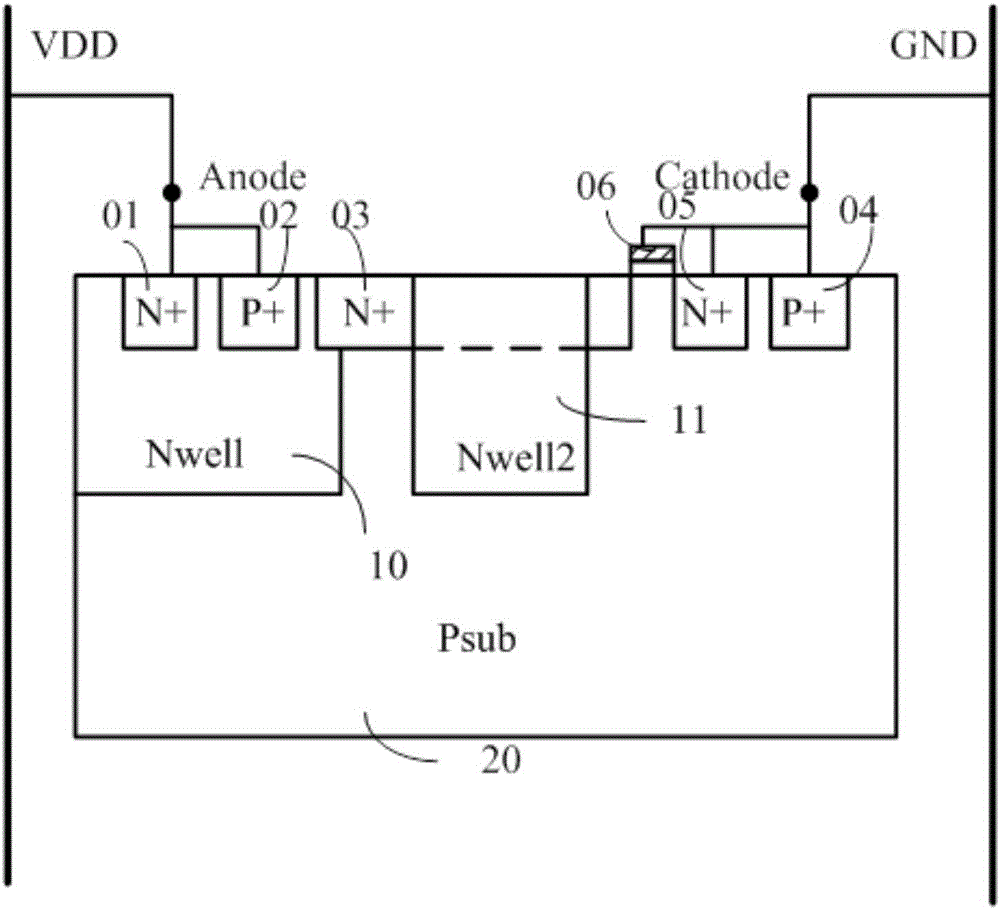

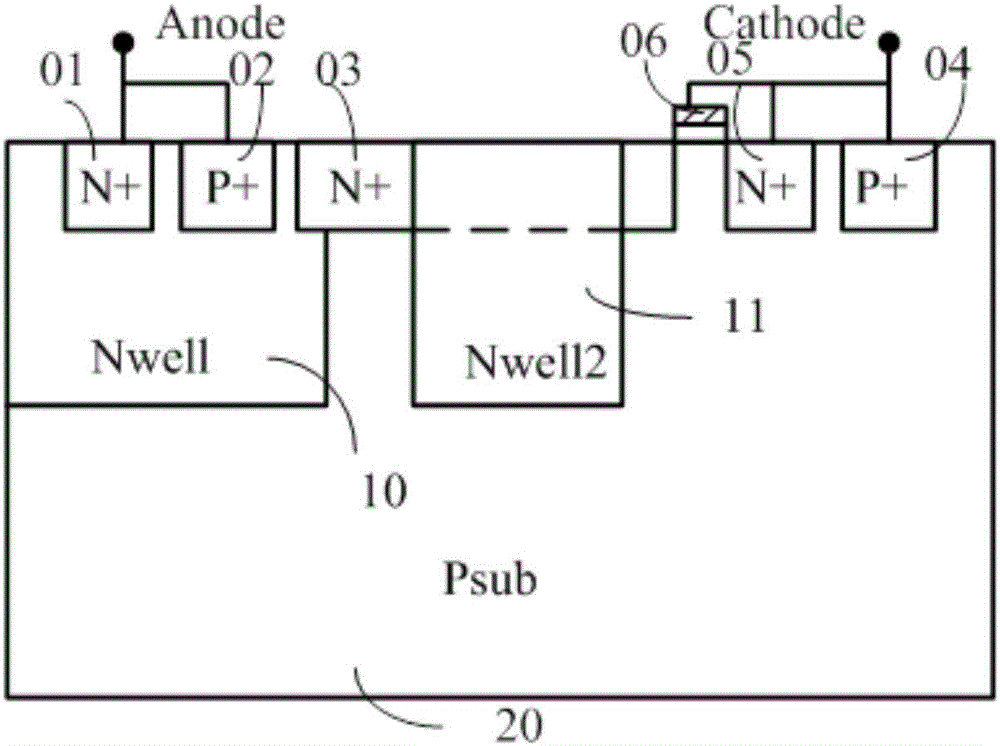

[0020] Such as figure 2 As shown, the latch-free SCR for ESD protection in this example includes a P-type substrate 20; the upper layer of the P-type substrate has a first N well 10, a surface N+ layer 03, a second N well 11, cathode contact N+ region 05, and cathode contact P+ region 04; the surface N+ layer 03 is partly located in the first N well 10, the upper layer of the second N well 11 overlaps with the surface N+ layer 03, and the surface N+ layer The horizontal width of 03 is greater than the horizontal width of the second N well 11; the upper layer of the first N well 10 has an anode contact N+ region 01 and an anode contact P+ region 02 that are independent of each other, and the anode contact P+ region 02 is located near the surface N+ layer 03 one side; the upper surface of the P-type substrate 20 between the surface N+ layer 03 and the cathode contact N+ region 05 has a gate 06; the anode contact N+ region 01 and the anode contact P+ region 02 are connected with...

Embodiment 2

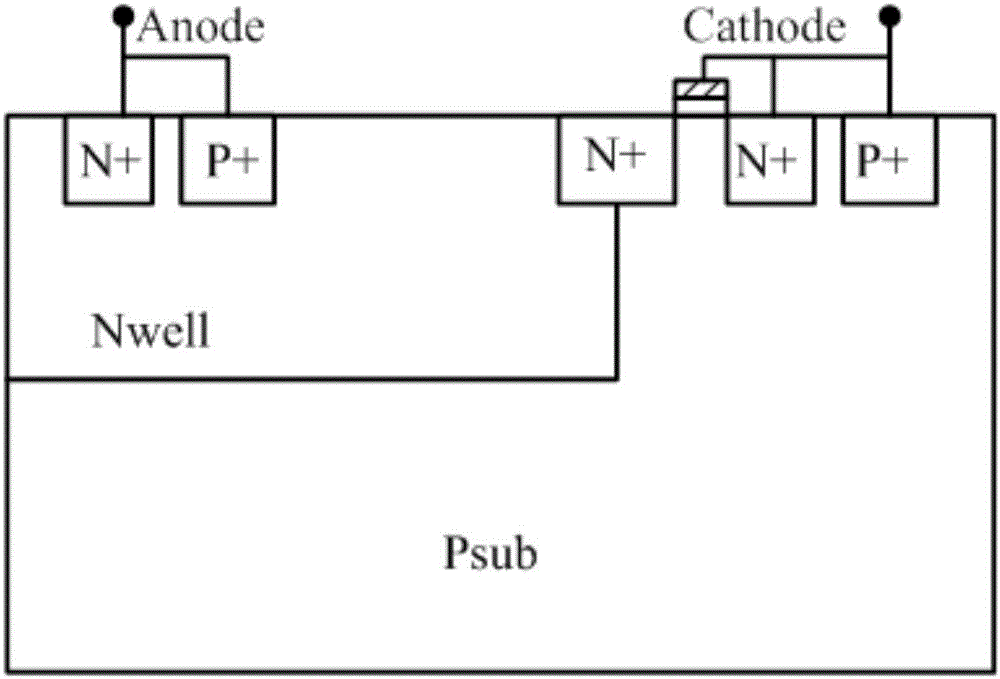

[0025] Such as Figure 4 As shown, the difference from Embodiment 1 is that the second N well 11 in Embodiment 1 needs to be removed and other structures remain unchanged.

[0026] Its working principle is basically the same as that of Embodiment 1, except that Embodiment 2 additionally uses the conduction of the second parasitic NPN transistor (by N+ / PSub+P+ / Nwell) to control the sustain voltage. The rest of the principles are basically the same.

Embodiment 3

[0028] Such as Figure 5 As shown, the difference from Embodiment 2 is that the second N well 11 needs to be removed and replaced with the Ptop layer 08, and other structures remain unchanged.

[0029] Its working principle is basically the same as that of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com