Identifying viscosity grade and new oil status based on dielectric and viscosity sensor

A sensor and viscosity technology, applied in viscometer maintenance, instruments, oil pans, etc., can solve problems such as unexplainable environmental conditions, engine component failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

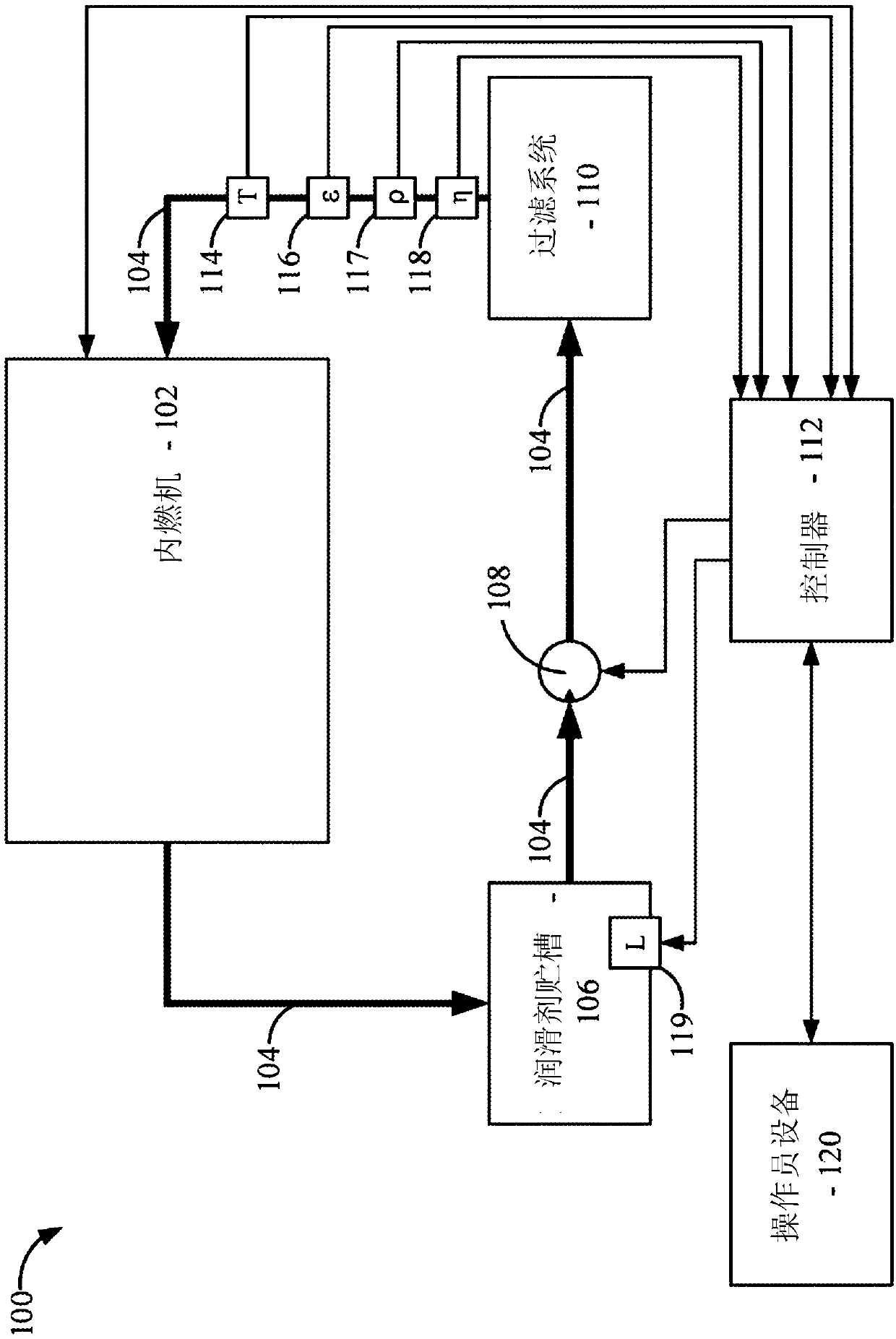

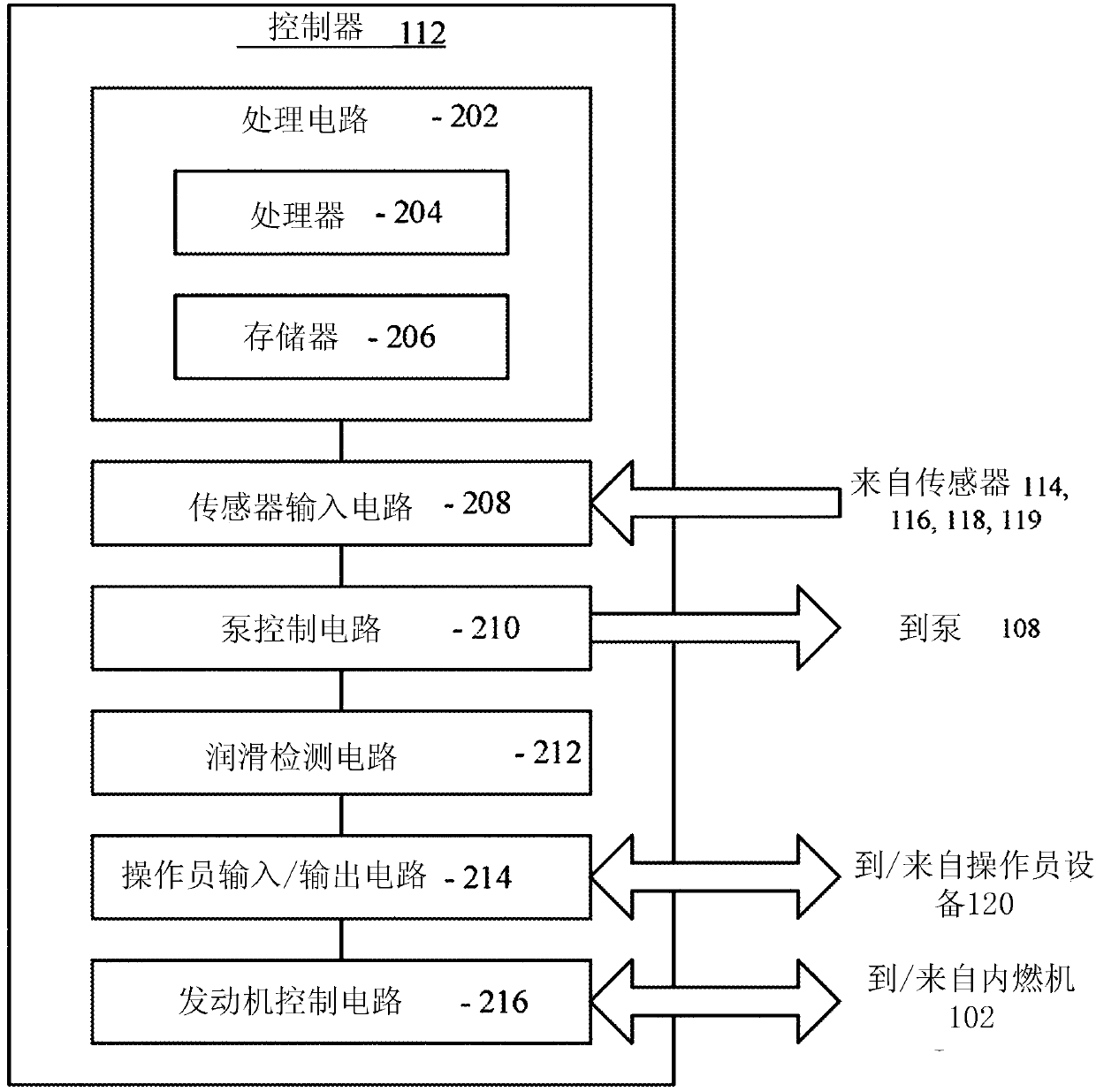

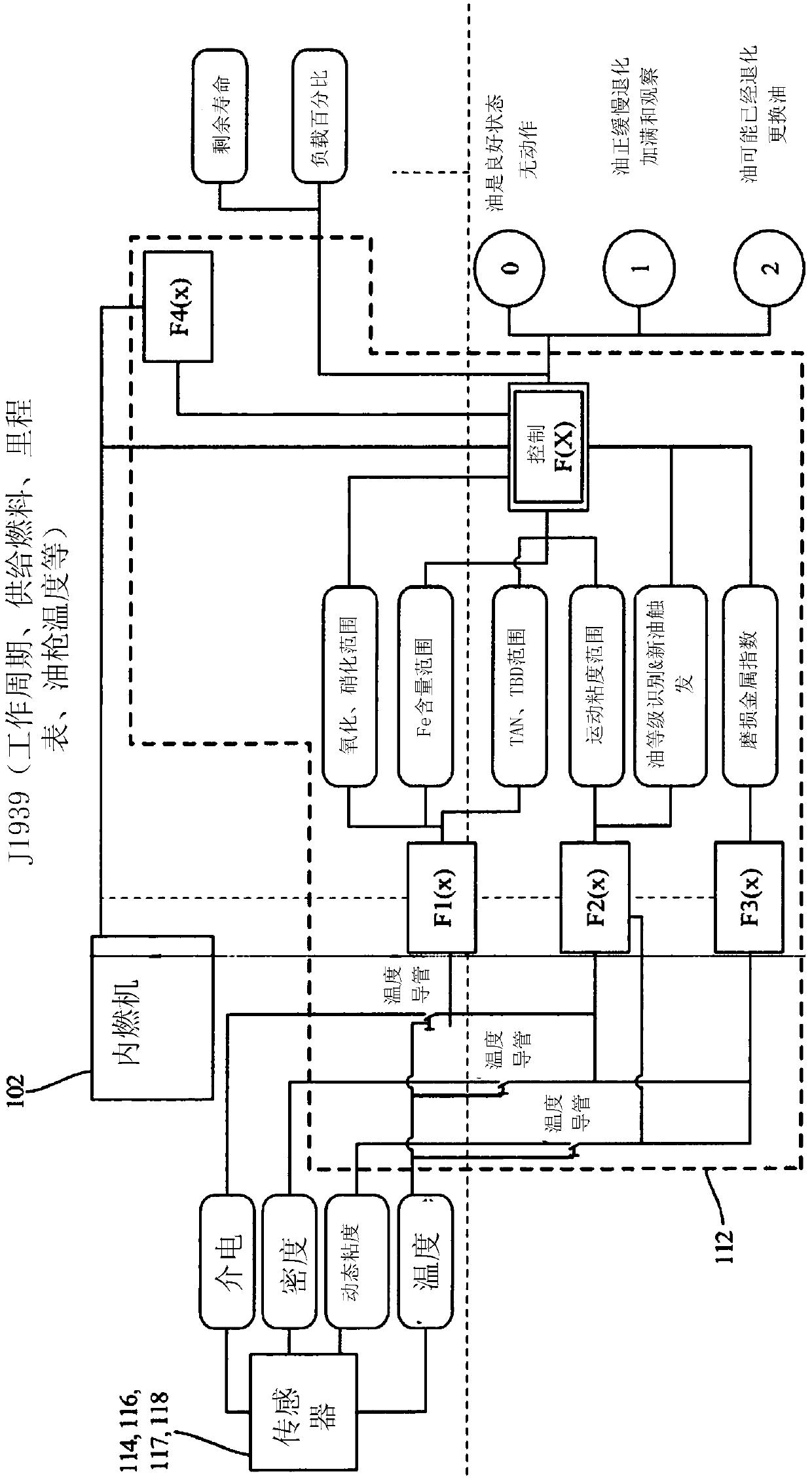

[0018] A lubrication system for an internal combustion engine and a method of monitoring the lubrication system are generally described with reference to the drawings. Lubrication systems typically circulate lubricant from a sump (ie, oil reservoir) through a filtration system to the internal combustion engine and back to the sump. The lubrication system includes a controller that monitors the dielectric constant of the lubricant and the viscosity of the lubricant. Based on the dielectric constant, the controller can determine whether the lubricant flowing through the lubrication system is new lubricant (e.g., recently replaced lubricant) or old lubricant (e.g., lubricant that has degraded enough to be distinguished from new lubricant) . If old lubricant is identified, the viscosity of that lubricant is compared to a threshold viscosity to dynamically determine when to change the lubricant. Similarly, in some embodiments, the described systems and methods can be used to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com