Feeding bowl

A technology for feeding basins and feeds, which is applied to animal feeding devices, packaging, containers, etc., can solve the problems of shortening, affecting the operation of equipment, and limited areas for de-arching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

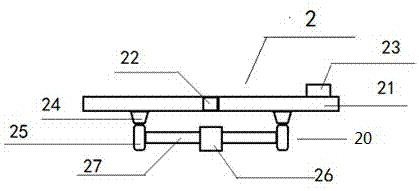

[0100] Combine below Figure 1 to Figure 20 , the present invention is further described:

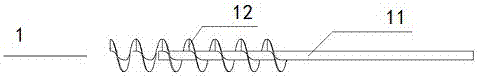

[0101] like figure 1 As shown, the rotary auger 1 is used in the feeder of the present invention to transport the dry feed in the bucket 7 to the feeding basin 8 . The rotary auger 1 is composed of a rotating rod 11 and a helical blade 12. One end of the helical blade 12 is axially distributed along the rotating rod 11, and the other end of the helical blade 12 exists independently and is not connected with the rotating rod 11. The independent helical blade 12 is axially distributed. To form a hollow part for placing the pushing and mixing rod 4.

[0102] In addition, the rotating auger 1 can also be a common rotating auger 1 , that is, the helical blades 12 are all connected to the rotating rod 11 .

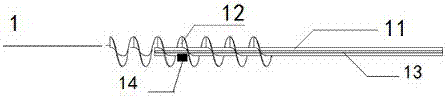

[0103] like figure 2 Shown, the second structure of the rotary auger 1 in the feeder of the present invention. The rotary auger 1 is composed of a rotating rod 11 and a helical blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com