Anti-blockage type wire mesh demisting device and method for applying same

A wire mesh defoaming and anti-clogging technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of easy clogging of the wire mesh and poor defoaming performance, so as to improve quality, prevent plugging and filling , the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

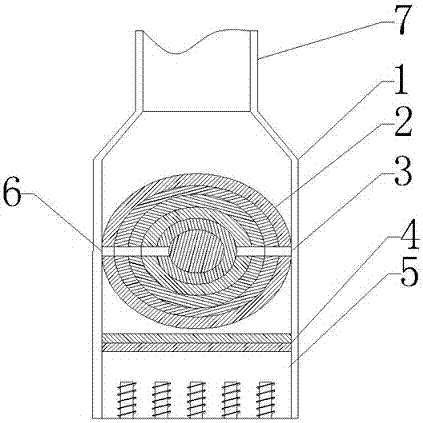

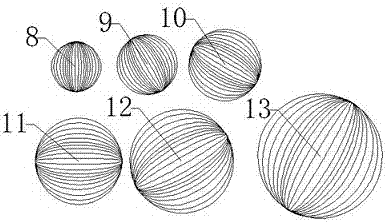

[0017] An anti-clogging type wire mesh defoaming device mainly includes a separation cover 1 and an exhaust port 7, the separation cover 1 is below the exhaust port 7, and a helical acceleration column 5 is respectively connected to the lowermost end of the separation tank 5, Above the nozzle of the helical acceleration column 5, a large-hole wire mesh defoaming separation net 4 is fixed, and above the large-hole wire mesh defoaming separation net, a spherical combined wire mesh defoaming net 2 is fixed by a central bearing 3. The spherical combined wire mesh de-foaming net 2 is a covering assembly, and from the inside to the outside, the spherical combined wire mesh de-foaming net 1 (8), the spherical combined wire mesh de-foaming net 2 (9), and the spherical combined wire mesh de-foaming net 2 (9). Net 3 (10), spherical combined wire mesh defoaming net 4 (11), spherical combined wire mesh anti-foaming net 5 (12), spherical combined wire mesh defoaming net 6 (13) six-layer ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com