A modified molecular sieve adsorbent for ammonia nitrogen wastewater treatment and preparation method thereof

A technology of ammonia nitrogen wastewater and molecular sieve, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unsatisfactory ammonia nitrogen adsorption rate and regeneration rate, and achieve favorable adsorption, The effect of improving the use intensity and reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

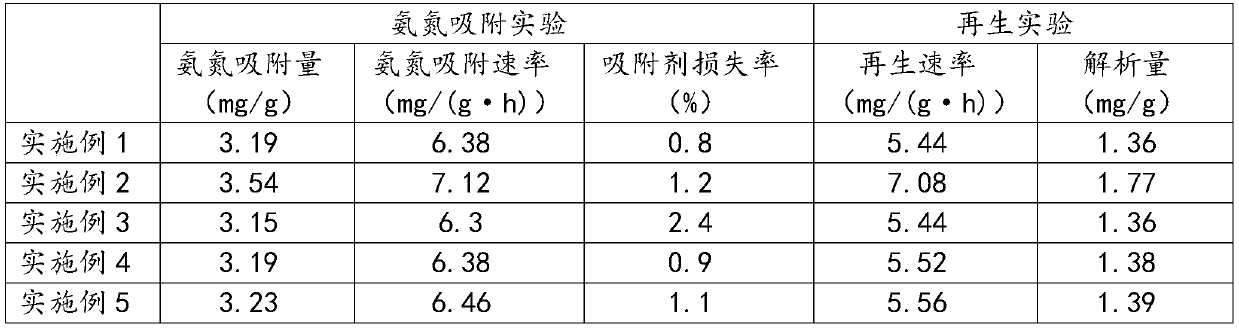

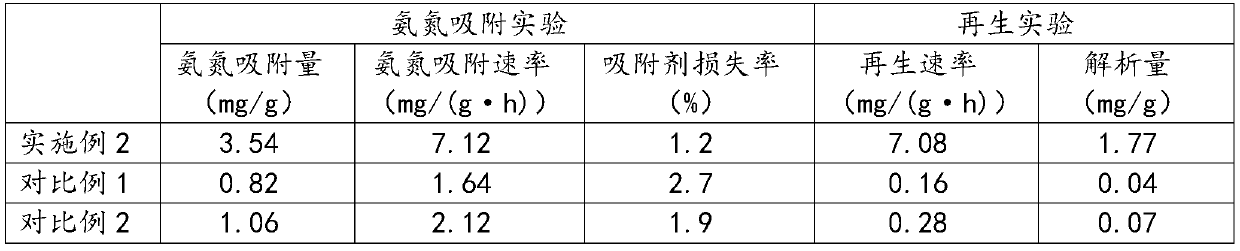

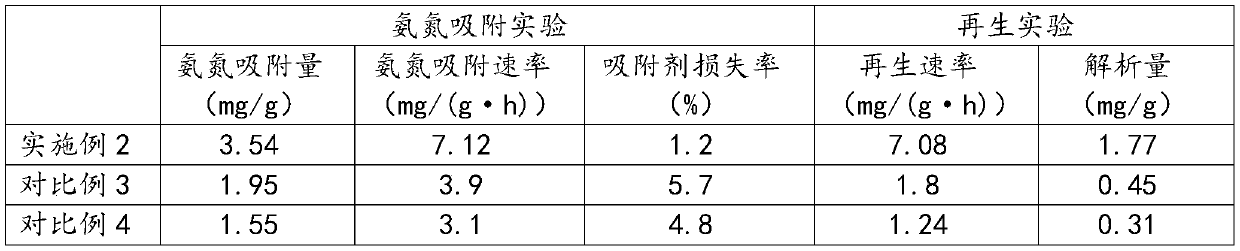

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a method for preparing a modified molecular sieve adsorbent for ammonia nitrogen wastewater treatment, comprising the following steps:

[0023] S1: uniformly mix ZSM-5 molecular sieve with binder, cross-linking agent, pore-forming agent and water to obtain mixed raw materials; wherein, the binder is pseudo-boehmite, and the cross-linking agent is hydrochloric acid and A mixed acid of nitric acid, and the pore-forming agent is squash powder.

[0024] S2: extruding the mixed raw materials, and calcining at 600° C. for 5 hours to obtain a modified molecular sieve adsorbent.

[0025] In the above preparation method, it should be noted that the ZSM-5 molecular sieve is a molecular sieve with a high silicon-aluminum ratio, which belongs to the medium-pore zeolite, and its skeleton is composed of two kinds of intersecting pore systems. Ellipse, the major axis is Minor axis is The other is a "Z"-shaped transverse channel wit...

Embodiment 1

[0034] (1) Weigh 50g ZSM-5 molecular sieve, 10g pseudo-boehmite and 2g scallop powder, place them in a blender and stir and mix evenly; take hydrochloric acid and nitric acid mixed with a mass ratio of 2:3 as cross-linking agent, weigh 3g Dissolve the cross-linking agent in 18g of water, then add the mixed cross-linking agent and water into the mixer under stirring conditions, mix with ZSM-5 molecular sieve, binder and pore-forming agent, and stir until completely uniform to obtain the mixed raw material;

[0035] (2) Pour the above mixed raw materials into an extruder and knead them, apply external pressure to make them extrude from a porous mold, let them dry for 24 hours, put them in an oven at 103°C for 2 hours, and then place them in a muffle furnace The modified molecular sieve adsorbent was obtained by calcining at 600°C for 5 hours.

Embodiment 2

[0037] (1) Weigh 50g ZSM-5 molecular sieve, 15g pseudoboehmite and 2.5g scallop powder, place them in a blender and stir and mix evenly; use hydrochloric acid and nitric acid mixed with a mass ratio of 2:3 as a crosslinking agent, weigh Dissolve 3g of cross-linking agent in 20g of water, then add the mixed cross-linking agent and water into the mixer under stirring conditions, mix with ZSM-5 molecular sieve, binder and pore-forming agent, and stir until completely uniform to obtain a mixed raw material;

[0038] (2) Pour the above mixed raw materials into an extruder and knead them, apply external pressure to make them extrude from a porous mold, let them dry for 24 hours, put them in an oven at 103°C for 2 hours, and then place them in a muffle furnace The modified molecular sieve adsorbent was obtained by calcining at 600°C for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com