A kind of mariculture wastewater treatment system and treatment method

A wastewater treatment system and mariculture technology, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problem of unfavorable nitrifying bacteria and denitrifying bacteria cultivation and domestication, low nitrogen removal efficiency, etc. problems, to achieve the effect of improving the transparency of the effluent, low cost, and solving the problem of purification and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

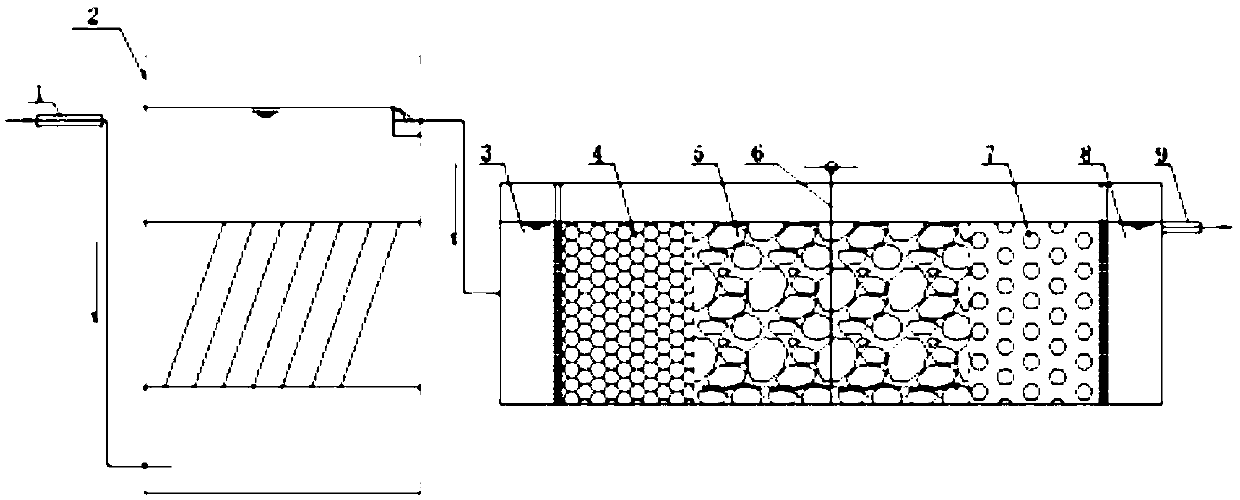

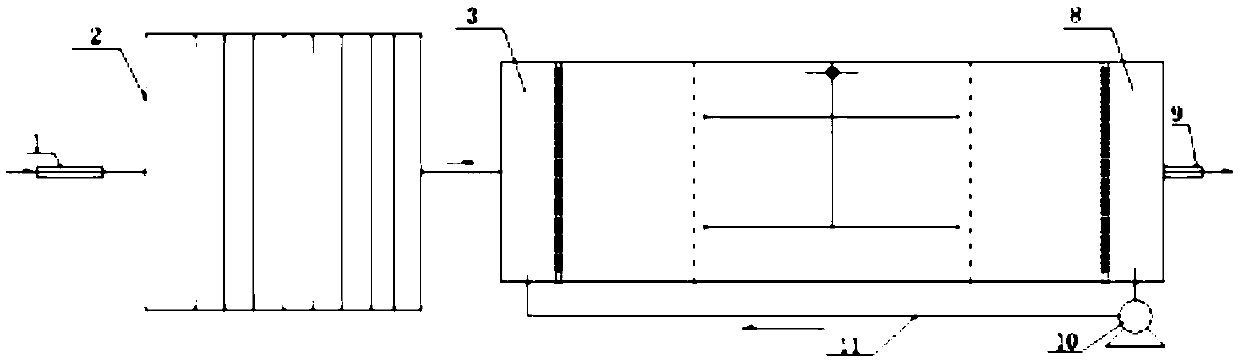

[0032] A kind of mariculture wastewater treatment system, such as figure 1 , figure 2 As shown, it includes a connected inclined plate sedimentation tank 2 and a three-stage denitrification and phosphorus removal pond, and the three-stage denitrification and phosphorus removal pond includes a water distribution area 3, an anoxic section (section A), and an aerobic section (section A) arranged in sequence. O section), phosphorus removal section and catchment area 8, the anoxic section is filled with gravel matrix 4, the aerobic section is filled with zeolite matrix 5, and perforated aeration tubes 6 are set, the phosphorus removal section is filled with phosphorus removal functional filler matrix 7, inclined plate The bottom of the sedimentation tank 2 is provided with a water inlet pipeline 1, the top of the inclined plate sedimentation tank 2 is connected with the water distribution area 3, and the water collection area 8 is provided with an outlet pipeline 9. A return pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com