A cleaning device for ceramic instruments

A technology for cleaning devices and instruments, applied in the field of teaching instruments, can solve the problems of low cleaning efficiency, easy to have chemical residues, and the bottom cannot be cleaned, and achieve the effect of improving the scope of application and improving the cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

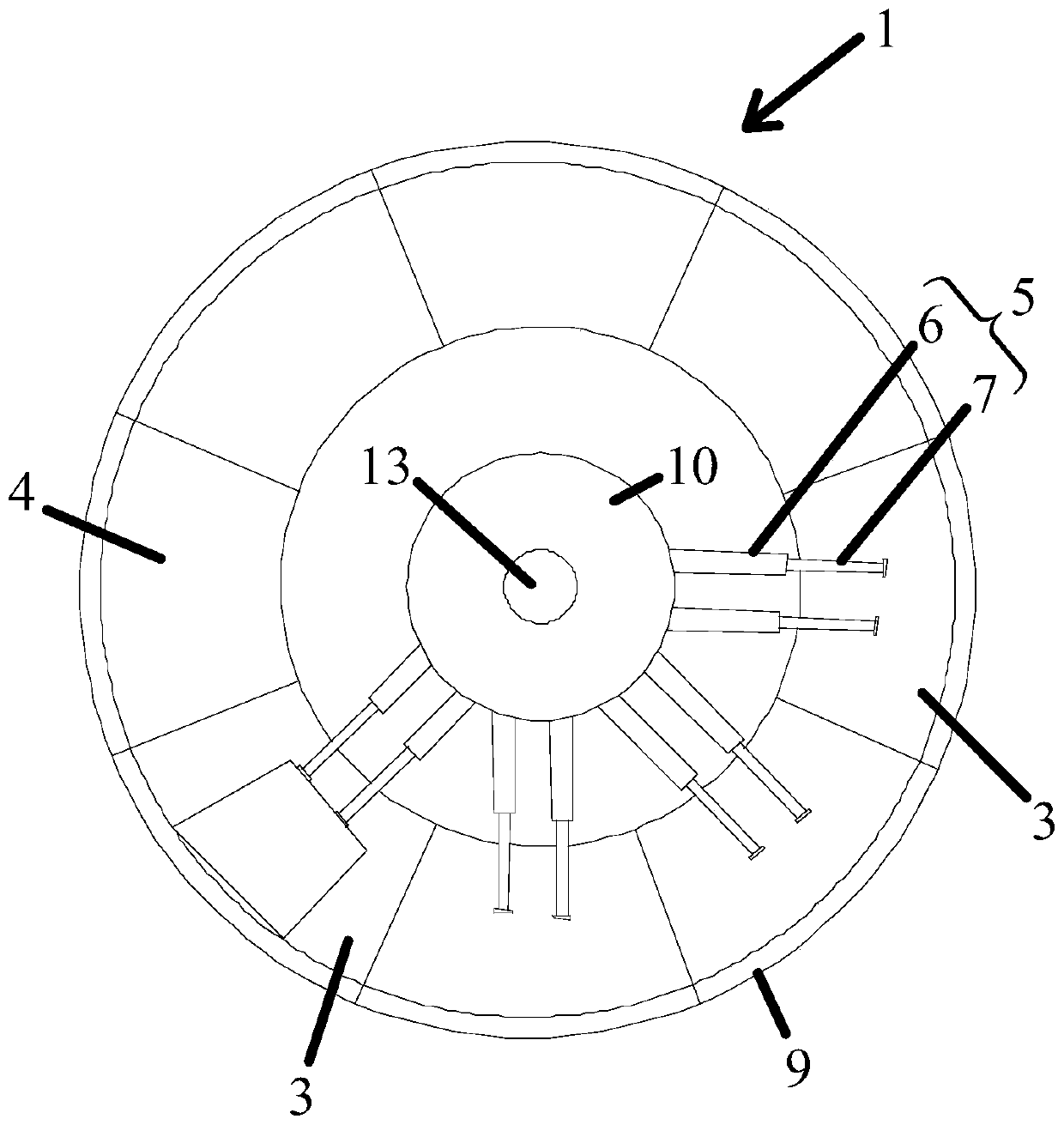

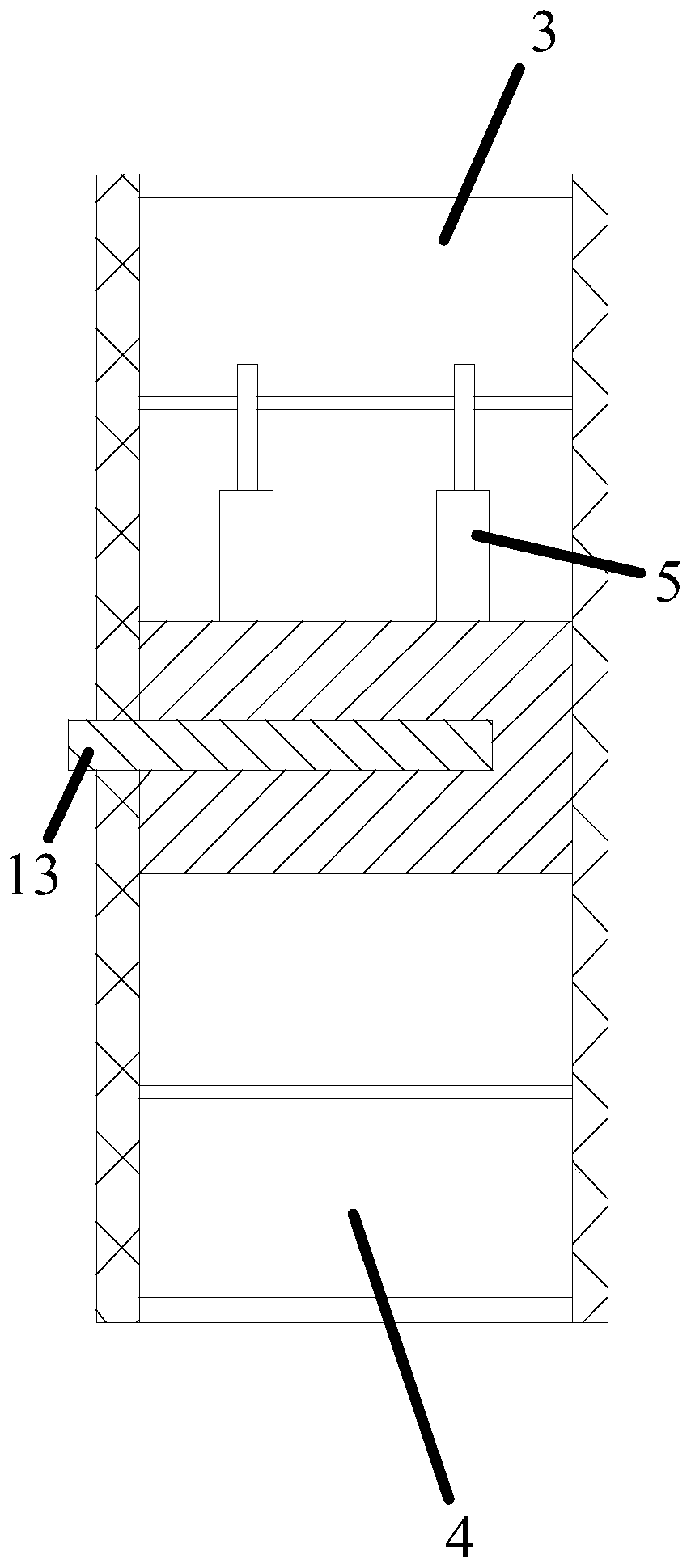

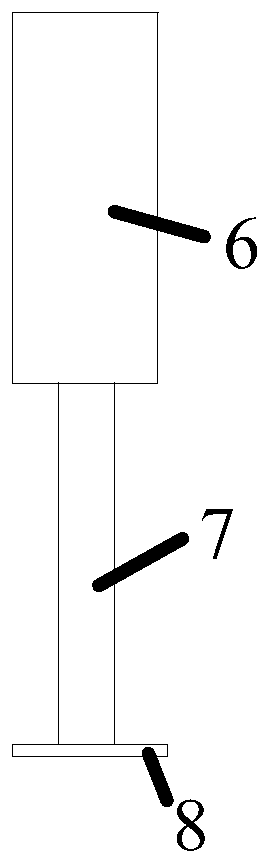

[0035] A cleaning device for ceramic instruments such as figure 1 with figure 2 shown, including:

[0036] Drum body 1, the inside of the drum body 1 is divided and formed with several cleaning chambers 2 provided with cleaning equipment for accommodating the ceramic instruments 3 to be cleaned, and the inside of the drum body 1 is also separated and formed with several chambers provided with drying equipment The drying chamber 4 is used to accommodate the ceramic instrument 3 to be dried; the shown drum body 1 includes a barrel-shaped shell 9, which is arranged at the axial center of the barrel-shaped shell 9 to fix the support column 10 of the telescopic device 5 , the annular partition 11 arranged between the barrel-shaped casing 9 and the support column 10, and the radial sealing partition 12 between the annular partition 11 and the barrel-shaped casing 9, the One end of the radial seal partition 12 is connected to the annular partition 11, and the other end is connect...

Embodiment 2

[0046] A cleaning device for ceramic instruments such as figure 1 with figure 2 shown, including:

[0047] Drum body 1, the inside of the drum body 1 is divided and formed with several cleaning chambers 2 provided with cleaning equipment for accommodating the ceramic instruments 3 to be cleaned, and the inside of the drum body 1 is also separated and formed with several chambers provided with drying equipment The drying chamber 4 is used to accommodate the ceramic instrument 3 to be dried; the shown drum body 1 includes a barrel-shaped shell 9, which is arranged at the axial center of the barrel-shaped shell 9 to fix the support column 10 of the telescopic device 5 , the annular partition 11 arranged between the barrel-shaped casing 9 and the support column 10, and the radial sealing partition 12 between the annular partition 11 and the barrel-shaped casing 9, the One end of the radial seal partition 12 is connected to the annular partition 11, and the other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com