Recyclable agricultural mulch punching equipment

A technology for perforating equipment and mulching film, which is applied in the fields of botanical equipment and methods, plant protection cover, gardening, etc., can solve the problems of inability to automatically collect waste films, and difficulty in equidistant perforation, so as to save labor costs and ensure stability. Growth, easy to drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

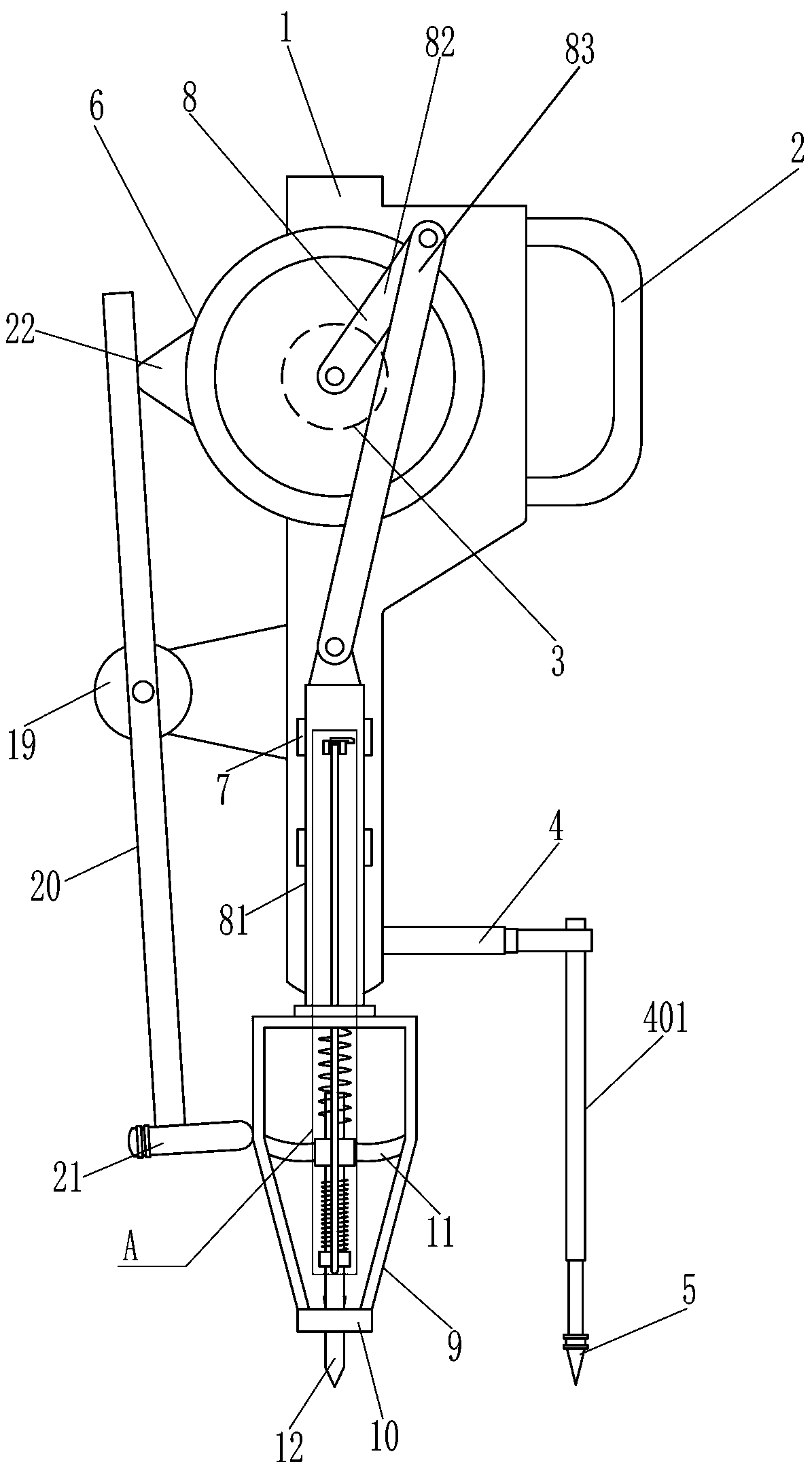

[0018] A recyclable agricultural film punching equipment, such as Figure 1-2 As shown, it includes a slide rail plate 1, a handle 2, a drive motor 3, a first telescopic rod 4, a second telescopic rod 401, a plug 5, a disc 6, a slider 7, an up and down reciprocating device 8, an installation frame 9, Cutting ring 10, guide plate 11, barb insert rod 12 and first compression spring 13, handle 2 is provided on the upper right side of slide rail plate 1, drive motor 3 is provided on the upper front side of slide rail plate 1, slide rail plate 1 The lower part of the right side is provided with the first telescopic link 4, the first telescopic link 4 right part is provided with the second telescopic link 401, the second telescopic link 401 end is provided with the plug 5, and the drive motor 3 front end output shaft is connected with the disc 6, slides The lower part of the rail plate 1 is slidably connected with sliders 7 up and down, and the front ends of the sliders 7 on both si...

Embodiment 2

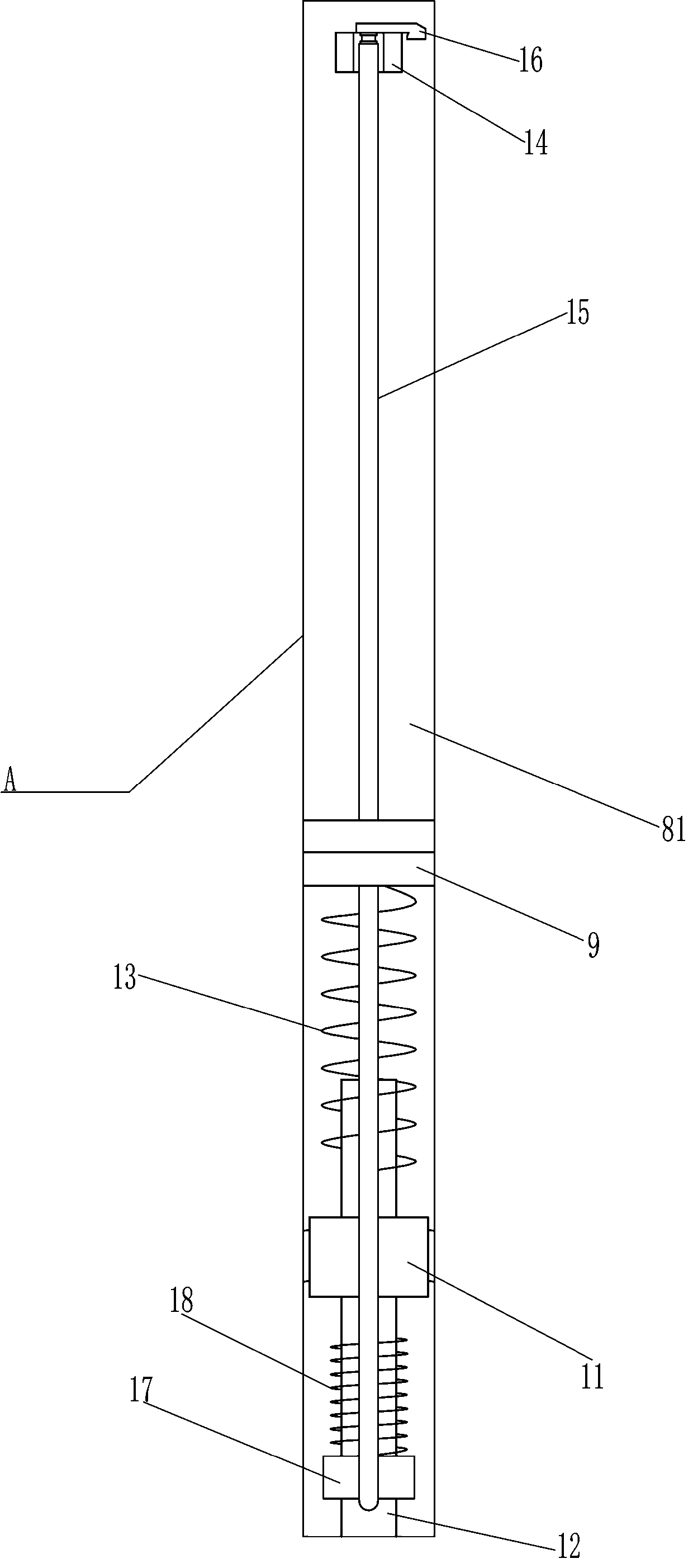

[0022] On the basis of Example 1, such as Figure 1-2 As shown, it also includes a block 14, a slide bar 15, a support plate 16, a push sleeve 17 and a second compression spring 18. The upper part of the front side of the strip plate 81 is provided with a block 14, and the block 14 is slidably connected with a sliding Rod 15, the lower part of the sliding rod 15 is slidably connected with the top of the installation frame 9, the sliding rod 15 is located at the front side of the guide plate 11, the rear side of the lower part of the sliding rod 15 is provided with a push sleeve 17, and the push sleeve 17 is slidably connected with the barbed insertion rod 12 , the top of the push sleeve 17 is connected with a second compression spring 18, the top of the second compression spring 18 is connected with the upper part of the barb insertion rod 12, the second compression spring 18 is in a compressed state, and the top of the slide bar 15 is rotatably connected with a support plate 1...

Embodiment 3

[0025] On the basis of Example 2, such as figure 1 Shown, also include supporting base 19, rotating rod 20, rubber percussion column 21 and rubber bump 22, slide rail plate 1 left side lower part is provided with supporting base 19, is connected with rotating rod 20 in the rotating type on supporting base 19, The end of the rotating rod 20 is connected with a rubber percussion post 21 , and the rear side of the disk 6 is provided with a rubber bump 22 .

[0026] When the disc 6 rotates, the disc 6 drives the rubber bump 22 to rotate, and through the cooperation of the rubber bump 22 and the rotating rod 20, the rubber knocking post 21 knocks the surface of the installation frame 9 intermittently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com