Method for conducting multi-pass flaring forming on plate type heat exchanger bushing ring

A plate heat exchanger and forming plate technology, applied in heat exchange equipment and other directions, can solve the problems of increasing the maintenance difficulty of the heat exchanger, affecting the service life of the heat exchanger, affecting the appearance of the product, etc., so as to improve the processing efficiency and forming quality, The effect of preventing cracking and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] A method for forming a lining ring of a plate heat exchanger by multi-pass flaring, comprising the following steps:

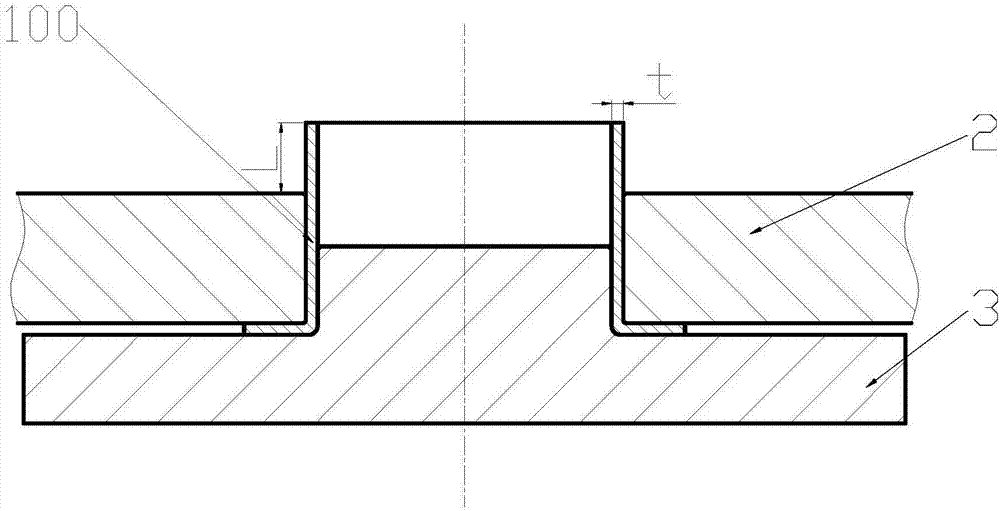

[0025] 1), refer to figure 1 , the tube blank 100 is assembled in the inner hole of the plate heat exchanger plate 2, supported on the lower mold 3, and the lower mold 3 provides support for the inner wall of the tube blank 100 and the rounded corners of the lower flange of the tube blank 100 to prevent the occurrence of deformation;

[0026] 2), flaring forming:

[0027] 2.1), refer to figure 1 , according to the thickness t of the tube blank 100 and the length L of the free end to determine the flaring passes, generally take 1 to 3 passes, this embodiment uses two passes of flaring, the first time using 20 ° flaring die 1, the second Adopt 45° flaring die 4;

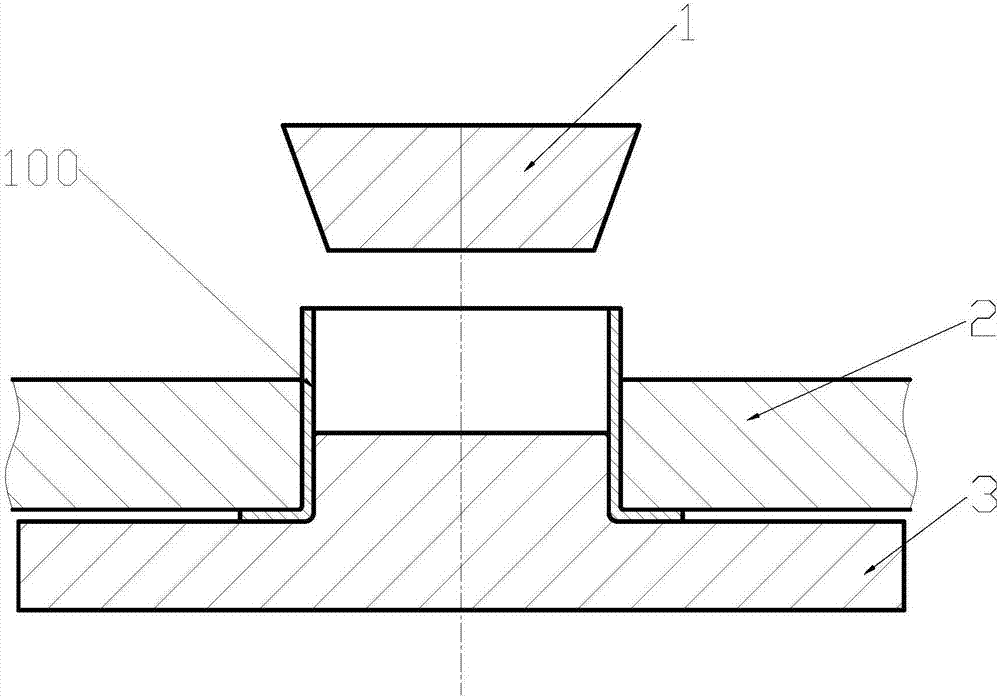

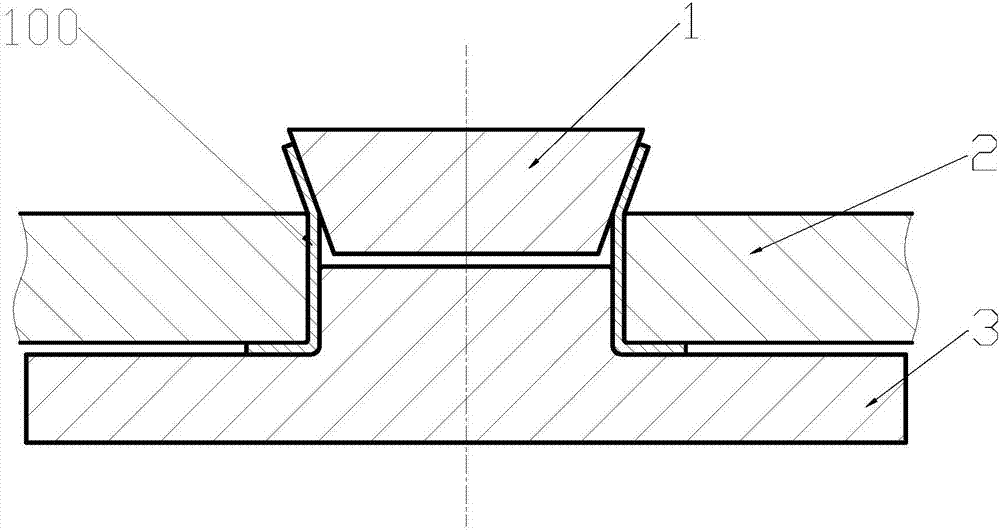

[0028] 2.2), refer to figure 2 and image 3 , the 20° flari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com