Air-blowing vibrator

A vibrating machine and air blowing technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of aluminum chip adhesion and poor effect, reduce fatigue wear, avoid negative effects, The effect of reducing correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

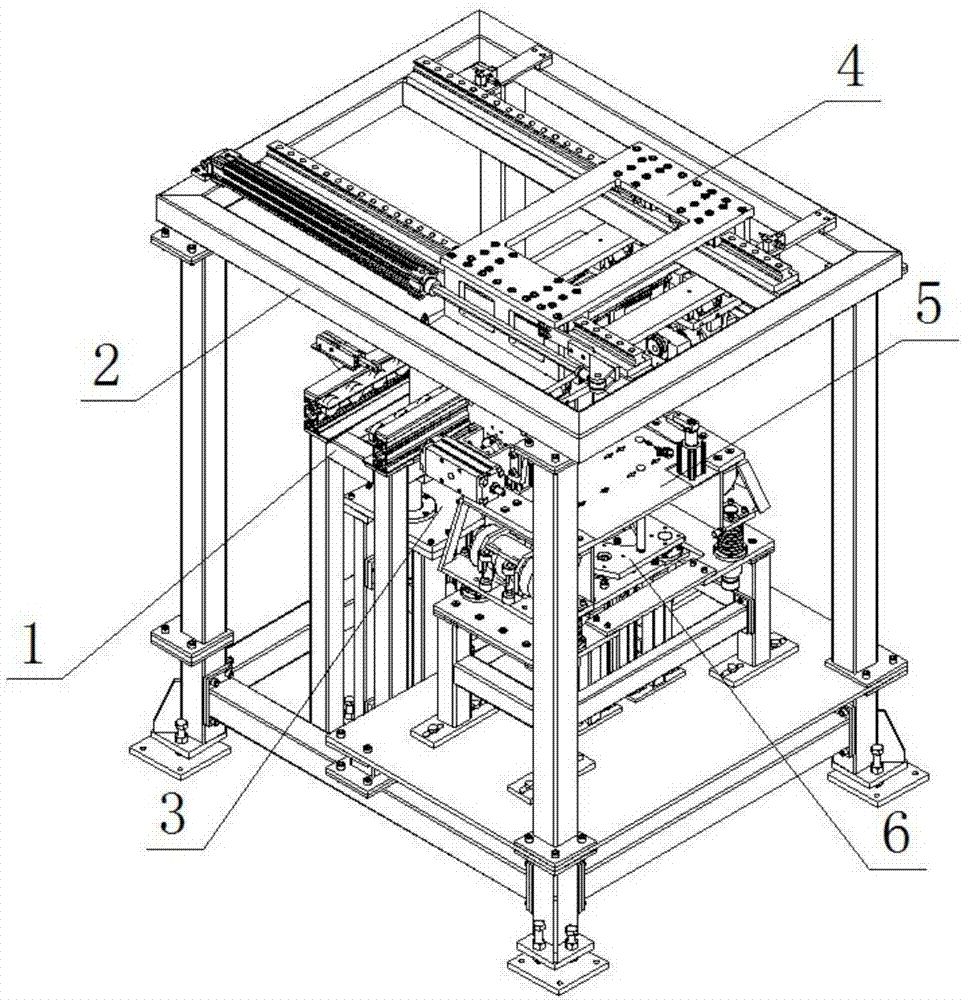

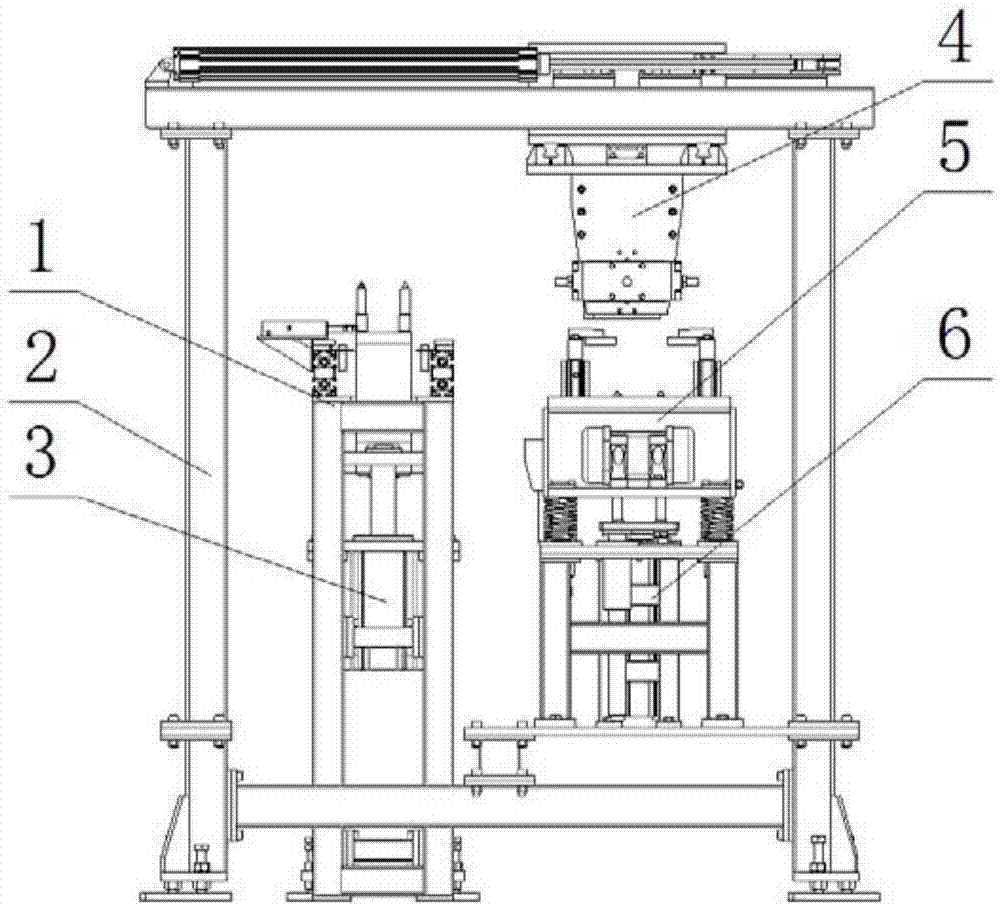

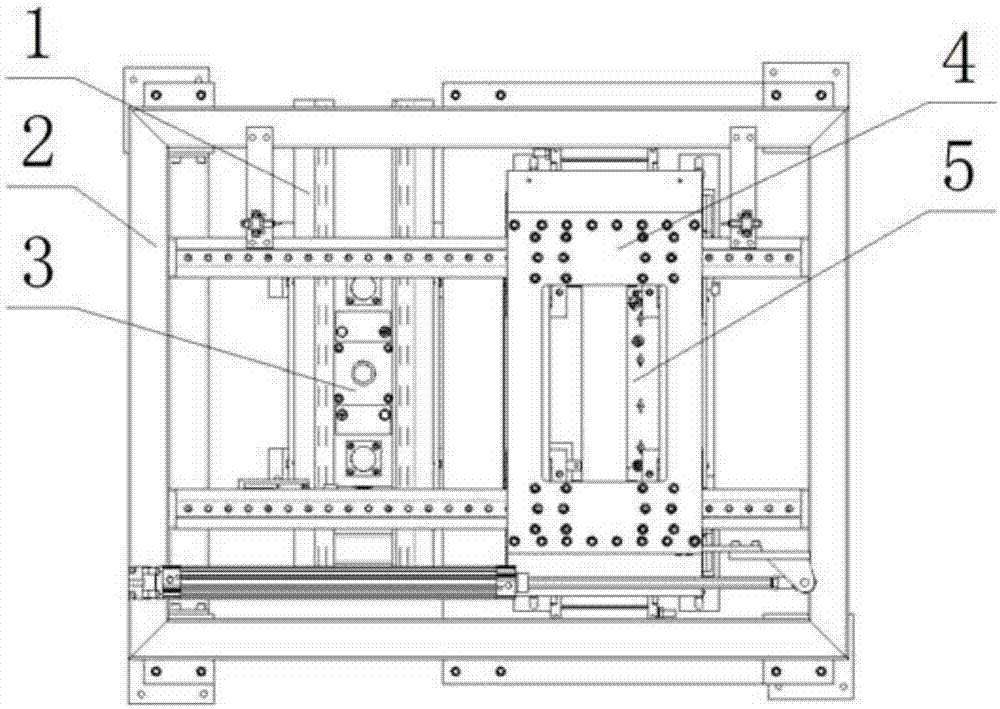

[0045] Such as Figure 1-3 As shown, a kind of air blowing vibration machine provided by the present invention includes a body frame 2, a lifting structure 3 under the conveying line body, a turning and translation structure 4, an air blowing vibration structure 5 and an air blowing vibration jacking structure 6, wherein the body frame 2 across the workpiece conveying line body 1, the workpiece conveying line body 1 is used to convey the automobile engine cylinder head that needs further processing; The workpiece on the workpiece conveying line body 1; the flip translation structure 4 is arranged on the top of the body frame 2, and is used to take away the workpiece ejected from the lifting structure 3 under the conveying line body and transfer it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com