Sodium sulfide and rongalite composite acidic reductive cleaning agent and preparation method and application thereof

A technology of carving white powder and sodium sulfide, applied in the field of dyeing and finishing, can solve the problems of high product cost, yellowing, poor cleaning effect, etc., achieve low cost, reduce water consumption, and avoid unstable pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

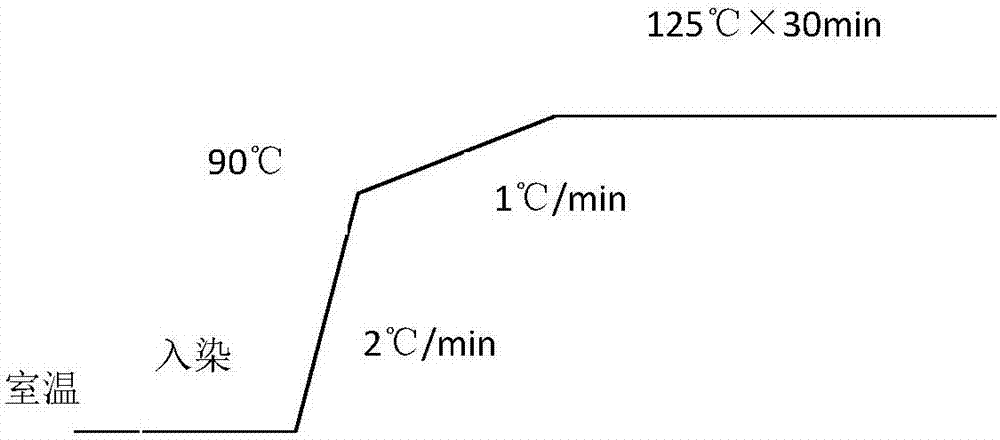

Method used

Image

Examples

Embodiment 1

[0027] A sodium sulfide white powder composite acid reduction cleaning agent is composed of sodium sulfide 0.5g / L, white powder 0.2g / L, AEO-90.1g / L and water.

[0028] The preparation method of the sodium sulfide carved white powder composite acid reduction cleaning agent is to mix sodium sulfide, carved white powder, AEO-9 and water.

[0029] The application of this sodium sulfide carved white powder composite acid reduction cleaning agent comprises the following steps:

[0030] 1) After the polyester fabric is dyed with disperse dyes, empty the dyeing residue in the polyester fabric;

[0031] 2) Add sodium sulfide carving white powder composite acid reduction cleaning agent and water to the polyester fabric after the dyeing residue is emptied in step 1), and then add acetic acid to adjust the pH value to 5;

[0032] 3) Keep warm at 80°C for 20 minutes, and finally wash and dry with water.

Embodiment 2

[0034] A sodium sulfide white powder composite acid reduction cleaning agent is composed of sodium sulfide 0.1g / L, white powder 0.5g / L, AEO-90.1g / L and water.

[0035] The preparation method of the sodium sulfide carved white powder composite acid reduction cleaning agent is to mix sodium sulfide, carved white powder, AEO-9 and water.

[0036] The application of this sodium sulfide carved white powder composite acid reduction cleaning agent comprises the following steps:

[0037] 1) After the polyester fabric is dyed with disperse dyes, empty the dyeing residue in the polyester fabric;

[0038] 2) Add sodium sulfide carving white powder composite acid reduction cleaning agent and water to the polyester fabric after the dyeing residue is emptied in step 1), and then add acetic acid to adjust the pH value to 5;

[0039] 3) Keep warm at 80°C for 20 minutes, and finally wash and dry with water.

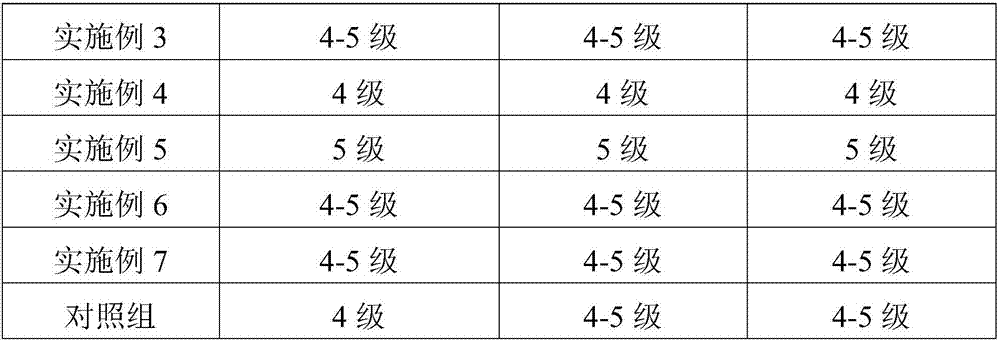

Embodiment 3

[0041] A sodium sulfide white powder composite acid reduction cleaning agent is composed of sodium sulfide 0.2g / L, white powder 0.3g / L, AEO-90.6g / L and water.

[0042] The preparation method of the sodium sulfide carved white powder composite acid reduction cleaning agent is to mix sodium sulfide, carved white powder, AEO-9 and water.

[0043] The application of this sodium sulfide carved white powder composite acid reduction cleaning agent comprises the following steps:

[0044] 1) After the polyester fabric is dyed with disperse dyes, empty the dyeing residue in the polyester fabric;

[0045] 2) Add sodium sulfide carving white powder composite acid reduction cleaning agent and water to the polyester fabric after the dyeing residue is emptied in step 1), and then add acetic acid to adjust the pH value to 5;

[0046] 3) Keep warm at 80°C for 20 minutes, and finally wash and dry with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com