Multi-bucket hook-type bucket device for crushing of rock layer foundation

A rock layer and foundation technology, which is applied in the field of multi-bucket hook type bucket devices for rock layer foundation crushing, can solve the problems of large working load, large impact load, reduced service life of tooth rods and tooth tips, and increased cost, and achieves faster speed. Loosening, easy excavation and transport, increased strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

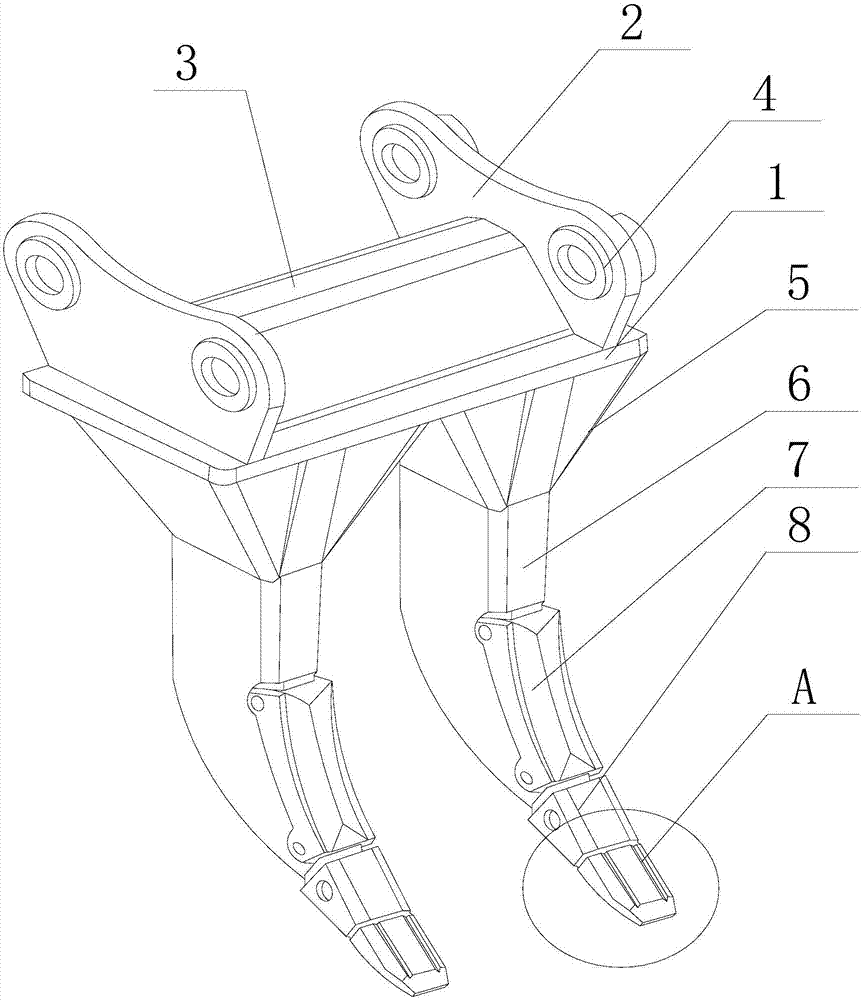

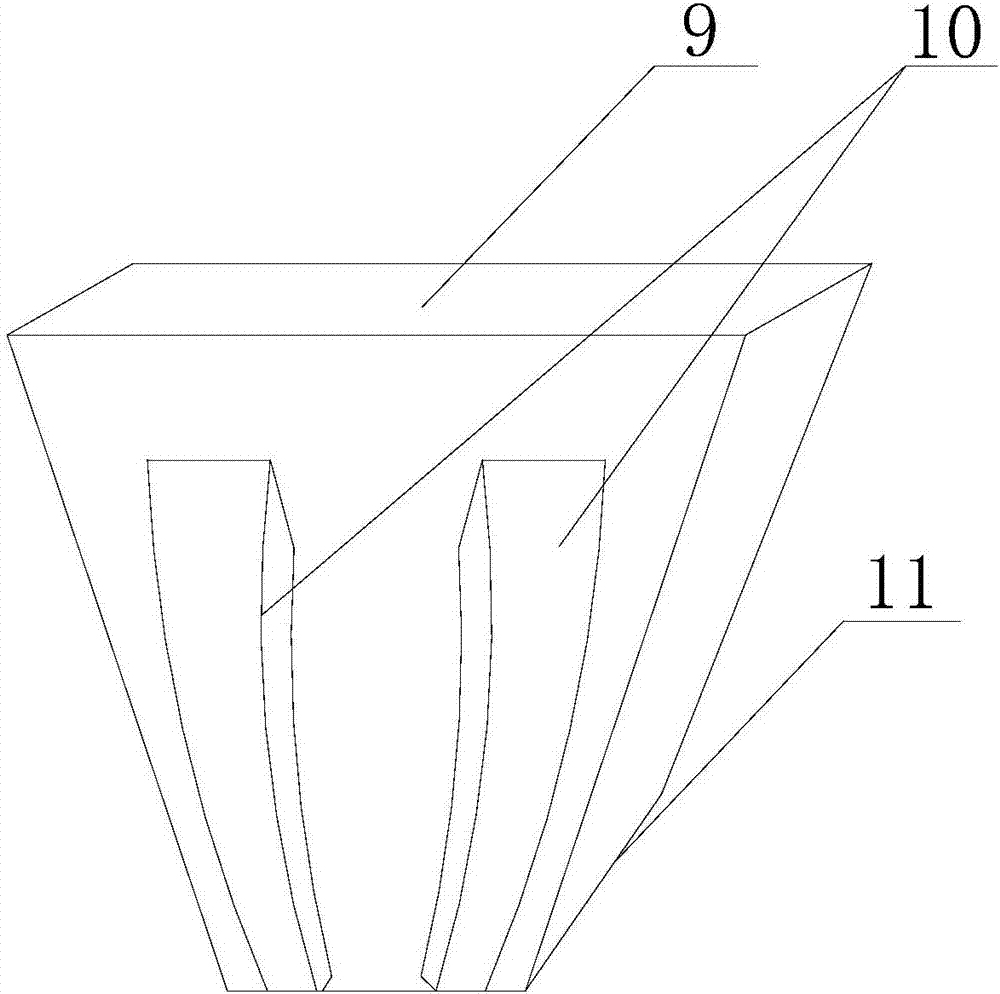

[0018] Such as figure 1 and figure 2 As shown, this embodiment includes a square connecting plate 1, ear plates 2 with shaft holes 4 are installed on both sides of the upper part of the connecting plate, and a trapezoidal reinforcing plate 3 is welded between the two ear plates 2, Weld two or more than two arc-shaped tooth bars 6 with bucket teeth 9 at the bottom middle position of the connecting plate 1, and connect with the outer wall of the tooth bar 6 at the square peripheral edge of the connecting plate 1 A reinforcing plate 5 is welded between them, and the distance between the upper ends of two adjacent gear rods 6 is 40-60 cm, and an alloy sheath 7 is installed on the inner side of the curved surface of the gear rod 6 through a pin shaft, A gear sleeve 8 is installed on the upper part of the bucket tooth 9 through a pin shaft, and two arc-shaped protrusions 10 are opened on the outer wall of the lower part of the bucket tooth 9, and the protrusions 10 point to the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com