Adhesive dispensing detection method, device and electronic device

A detection method and technology of detection device, which are applied in image data processing, instrumentation, calculation, etc., can solve problems such as heavy workload and easy missed inspection, and achieve the effect of not easily missed inspection, reducing workload, and facilitating inspection and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

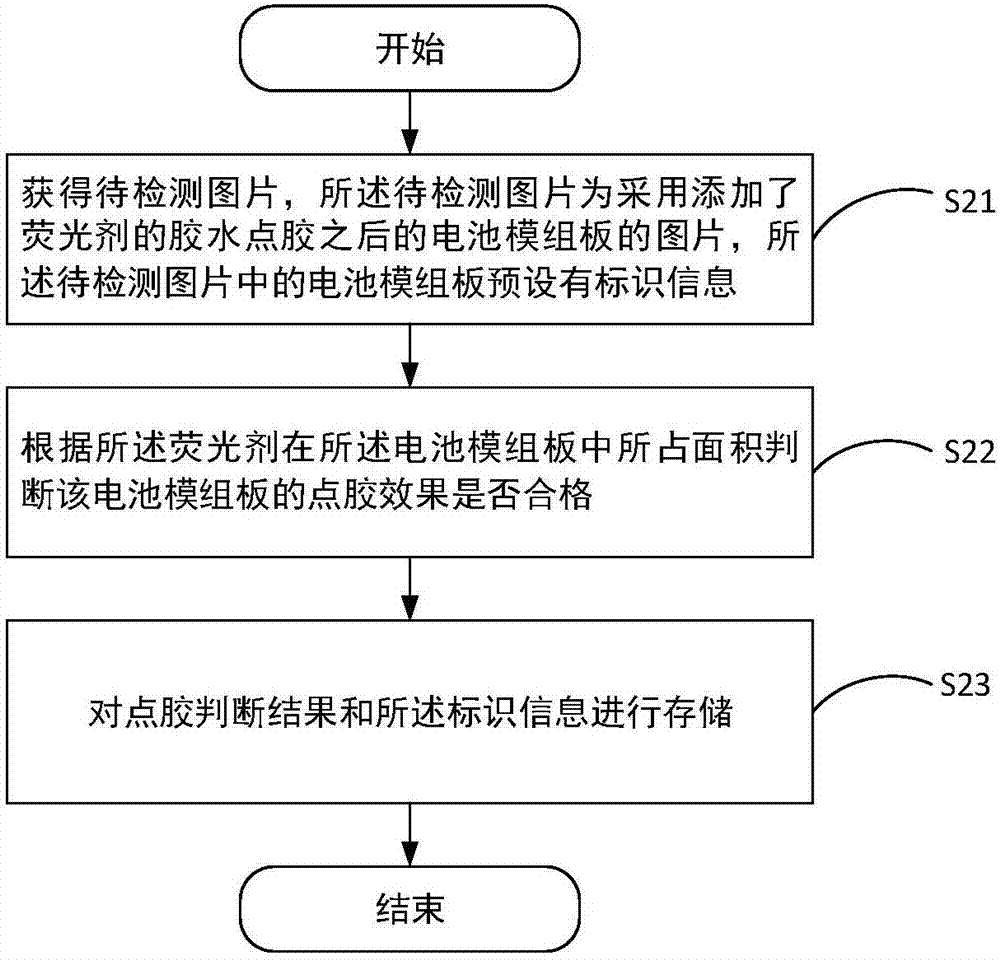

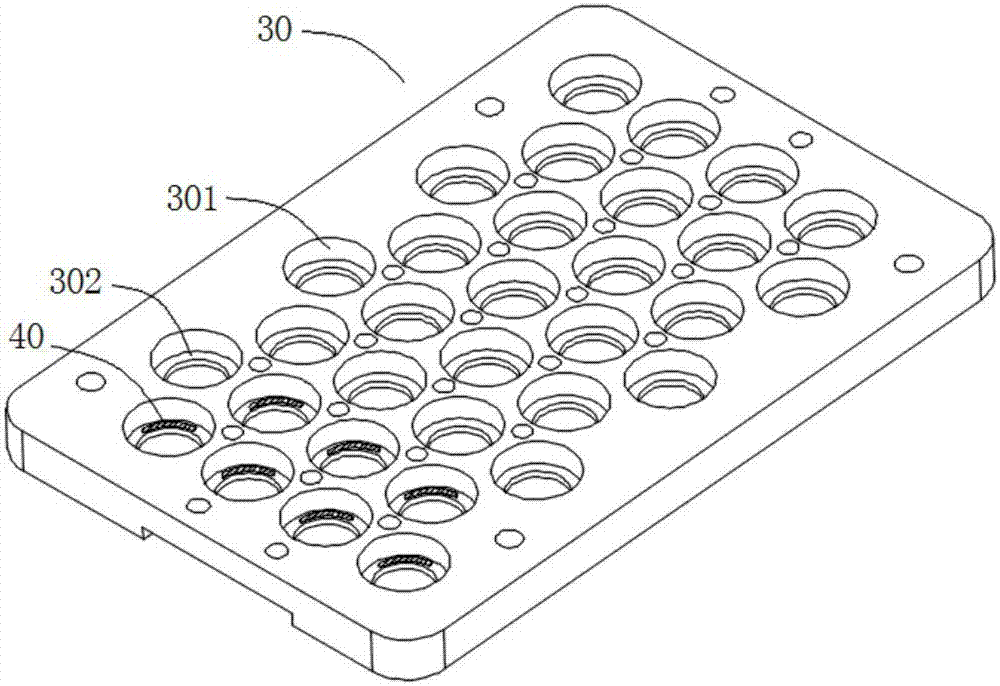

[0041] At present, the safety issue of electric vehicles has attracted more and more attention from people, and has also become an important indicator when people choose electric vehicles. As an important part of electric vehicles, the safety of battery modules is very important. During the manufacturing process of the battery module, glue is used to dispense the battery board.

[0042] After research, it is found that the current method of detecting the dispensing effect is mainly through manual inspection, which has a large workload and is easy to miss.

[0043] Based on the above research, an embodiment of the present invention provides a glue dispensing detection method, which can accurately detect the glue dispensing effect of the battery module board and reduce the workload.

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com