Motor case rolling forming device

A technology of casing and material blocking device, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of increasing the difficulty of welding work, increasing labor force, and large distances between joints, so as to facilitate the nearby pick and place, The effect of labor saving and distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

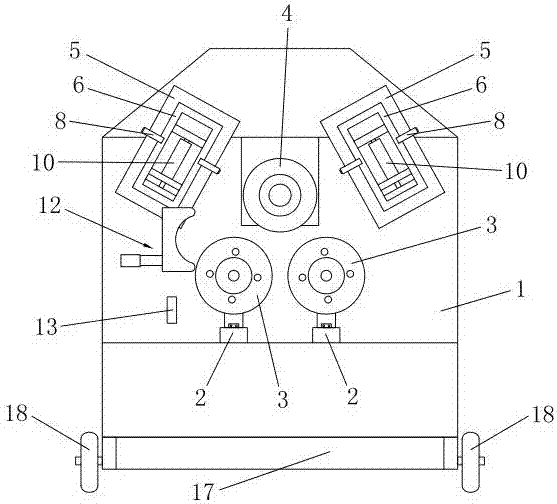

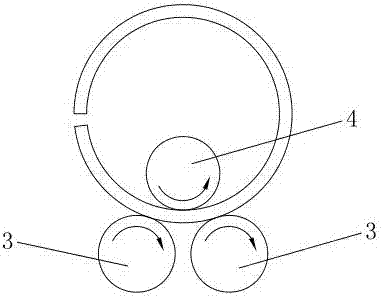

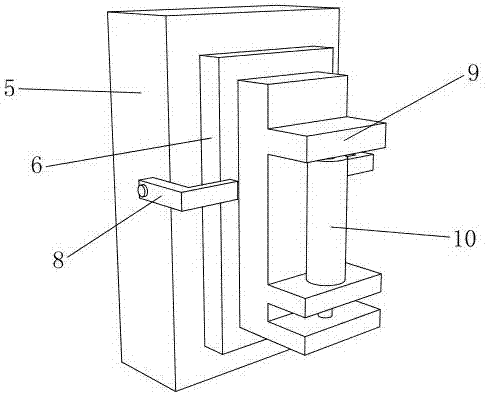

[0023] Such as Figure 1 to Figure 5 As shown, it is a rolling forming device for a motor case of the present invention, which includes a machine body 1 on which two pushing mechanisms 2 are arranged laterally. A first driving roller 3 is arranged on a single pushing mechanism 2, and the pushing mechanism 2 drives the first driving roller 3 up and down. The body 1 is provided with a second driving roller 4 , and the second driving roller 4 is arranged above the first driving roller 3 . The rotation direction of the second drive roller 4 is opposite to the rotation direction of the first drive roller 3 . The direction of rotation of the first driving roller 3 is clockwise, and the direction of rotation of the second driving roller 4 is counterclockwise, so that the plate can be passed into a certain length from the right to the left, and the first driving roller 3 rotates clockwise. , the sheet material moves to the right, and under the counterclockwise rotation of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com