Traveling mechanism of claw-thorn wall climbing robot

A technology of a wall-climbing robot and a walking mechanism, applied in the field of robots, can solve problems such as the inability to achieve rough surface grasping, and achieve the effects of improving stability and reliability, smooth switching, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

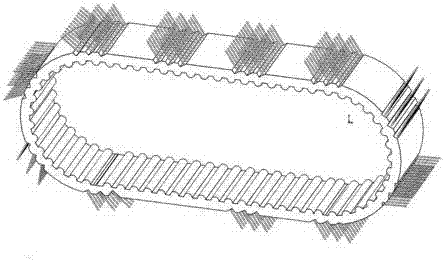

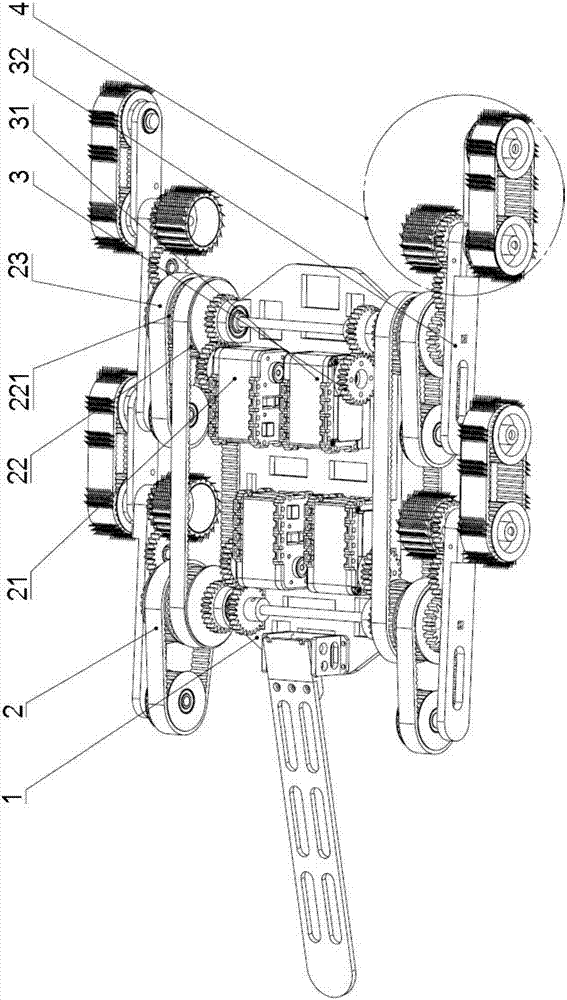

[0036] Such as Figure 1 ~ Figure 3 As shown, the structural relationship is as follows: it includes a chassis 1 for supporting and fixing, two main motion steering gears 21 and two switching steering gears 31 are arranged diagonally on the chassis 1, and the main motion steering gear 21 is used to drive the first crawling mechanism 2 and the second crawling mechanism 4 to realize the wall-climbing of the robot, the switching steering gear 31 is used to switch the first crawling mechanism 2 or the second crawling mechanism 4 to perform the wall-climbing action, and the first crawling mechanism 2 and the second crawling mechanism 4 use respectively Climbing on smooth and rough walls;

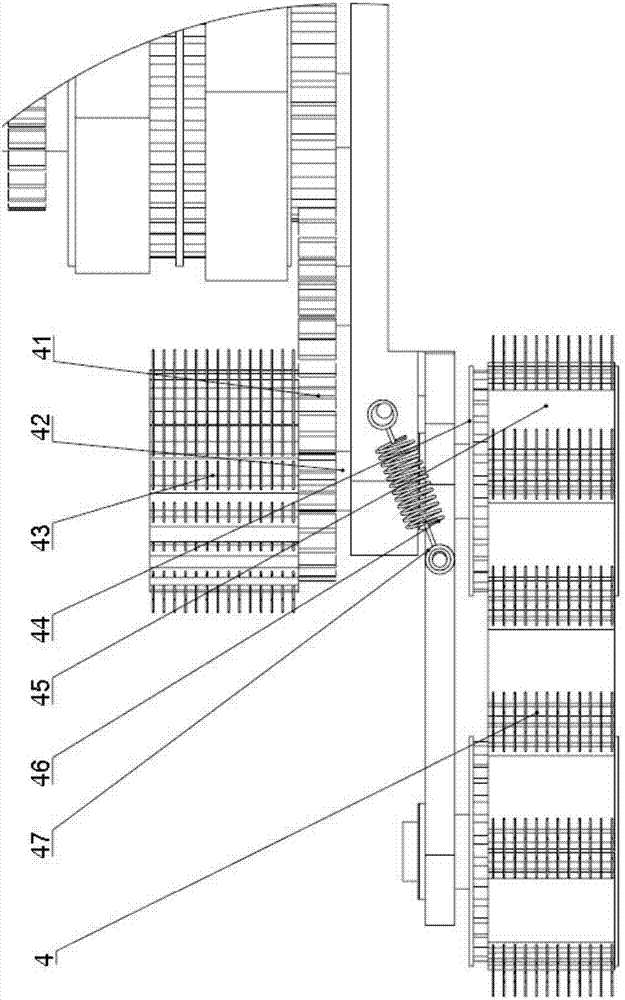

[0037] The synchronous shaft 42 is connected to the front end of the claw thorn pulley bracket 46 through a bearing, and its inner side is connected to the claw thorn pulley 43. The two claw thorn pulleys 44 are respectively located at the front end and the end of the claw thorn pulley bracket 46...

Embodiment 2

[0047] Such as Figure 1 ~ Figure 3 As shown, the structural relationship is as follows: it includes a chassis 1 for supporting and fixing, two main motion steering gears 21 and two switching steering gears 31 are arranged diagonally on the chassis 1, and the main motion steering gear 21 is used to drive the first crawling mechanism 2 and the second crawling mechanism 4 to realize the wall-climbing of the robot, the switching steering gear 31 is used to switch the first crawling mechanism 2 or the second crawling mechanism 4 to perform the wall-climbing action, and the first crawling mechanism 2 and the second crawling mechanism 4 use respectively Climbing on smooth and rough walls;

[0048] The synchronous shaft 42 is connected to the front end of the claw thorn pulley bracket 46 through a bearing, and its inner side is connected to the claw thorn pulley 43. The two claw thorn pulleys 44 are respectively located at the front end and the end of the claw thorn pulley bracket 46...

Embodiment 3

[0056] A method for installing a claw wheel of a claw-type wall-climbing machine, comprising the following steps: installing the claws in the pipeline of the claw wheel, and then adhering the pipeline to the groove of the claw.

[0057] At present, claws are generally installed directly in the grooves of the claws. The installation efficiency is extremely low, and it takes about 5 minutes for a single claw. At the same time, due to the limited contact area between the fixing glue and the claws, the claws are very easy to loosen and fall off.

[0058] In this method, the claws are installed in the pipeline of the claw wheel, and then the pipeline is bonded to the groove of the claws. The bonding strength is five times that of the method of directly installing the claws, and the installation efficiency is 5 per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com