Method and system for reducing content of heavy hydrocarbon in hydrocarbons prepared from methanol

A technology for producing hydrocarbons and heavy hydrocarbons from methanol, which is applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, etc., can solve the problems of reducing the economy of methanol-to-hydrocarbon units, low utilization value of heavy hydrocarbon resources, etc., and achieve high economic value and social benefits, The effect of reducing heavy hydrocarbon content and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

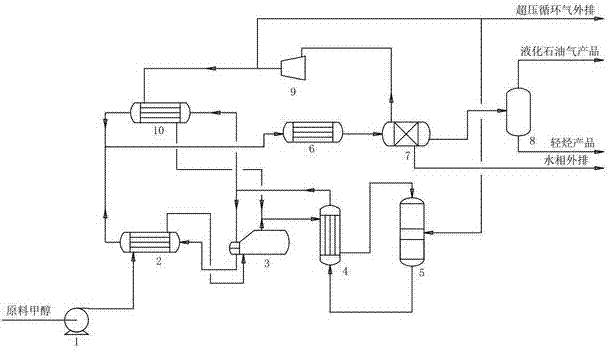

[0037] according to figure 1 According to the requirements of the process flow shown, the methanol flow rate is controlled at 100 kg / h, the methanol composition: 99.9%, the circulating gas flow rate is 500 kg / h, and the circulating gas composition: H 2 10%CH 4 60%C 2 h 4 10%C 2 h 6 20%; the above-mentioned methanol and cycle gas are pressurized to 2.0MPa.

[0038] The first stage of catalytic reactor 5 is at a mass space velocity of 20 h -1 , the temperature is 410℃, the pressure is 2.2 MPa; the second stage is at a mass space velocity of 1.5 h -1 , temperature 390 ℃, pressure 2.1 MPa process conditions;

[0039] The reaction result is as follows: the product light hydrocarbons are separated by the stabilizing tower 8, and the content of heavy hydrocarbons (durene) in the light hydrocarbon products is 1.8% after analysis.

Embodiment 2

[0041] according to figure 1 According to the requirements of the process flow shown, the methanol flow rate is controlled at 200 kg / h, the methanol composition: 95.0%, the circulating gas flow rate is 900 kg / h, and the circulating gas composition: H 2 10%CH 4 60%C 2 h 4 10%C 2 h 6 20%; the above-mentioned methanol and cycle gas are pressurized to 2.1MPa.

[0042] The first section of catalytic reactor 5 is at a mass space velocity of 25 h -1 , the temperature is 400℃, the pressure is 2.0 MPa; the second stage is at a mass space velocity of 1.0 h -1 , temperature 380 ℃, pressure 2.5 MPa process conditions;

[0043] The light hydrocarbons are separated by the stabilizing tower (10). After analysis, the content of heavy hydrocarbons (durene) in the light hydrocarbon products is 1.75%.

Embodiment 3

[0045] according to figure 1 According to the requirements of the process flow shown, the methanol flow rate is controlled at 200 kg / h, the methanol composition: 90.0%, the circulating gas flow rate is 900 kg / h, and the circulating gas composition: H 2 10%CH 4 60%C 2 h 4 10%C 2 h 6 20%; the above-mentioned methanol and cycle gas are pressurized to 2.5MPa.

[0046] The first stage of catalytic reactor 5 is at a mass space velocity of 50 h -1 , the temperature is 420℃, the pressure is 2.5 MPa; the second stage is at a mass space velocity of 1.2 h -1 , the process conditions of temperature 410 ℃ and pressure 1.9 MPa;

[0047] The light hydrocarbons are separated by the stabilizing tower (10). After analysis, the content of heavy hydrocarbons (durene) in the light hydrocarbon products is 1.93%.

[0048] The content of heavy hydrocarbons (durene) in the light hydrocarbon products produced in the above examples is far lower than the 8-10% level of heavy hydrocarbons (dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com