Method and device for recovering oil and gas

A technology for oil, gas and gasoline, which is applied in the recovery of liquid hydrocarbon mixture, gas fuel, petroleum industry, etc. It can solve the problems affecting the quality of ethylbenzene and styrene products, the heat load of the reboiler at the bottom of the tower, the increase of investment and energy consumption, etc. , to achieve the effects of easing operating conditions, reducing energy consumption, and cooling capacity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

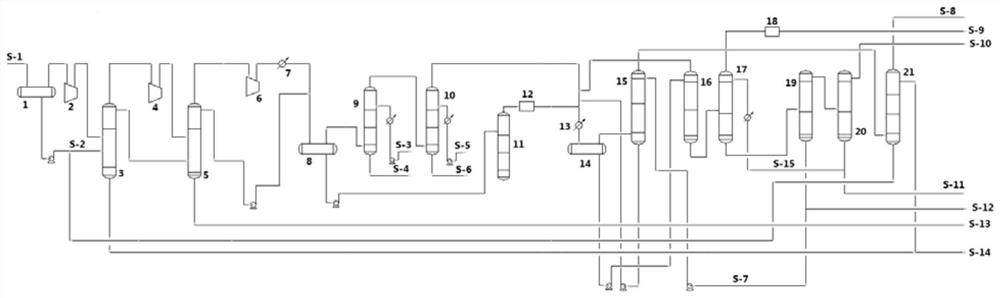

Embodiment 1

[0090] Devices for oil and gas recovery include:

[0091] Oil and gas feed line, gas-liquid separation tank I1, compressor I2, light and heavy gasoline separation tower 3, compressor II4, light hydrocarbon-light gasoline separation tower 5, compressor III6, cooler I7, gas-liquid separation tank II8 , rich gas desulfurization tower 9, rich gas alkali washing tower 10, liquid hydrocarbon desulfurization tower 11, liquid hydrocarbon desulfurization reactor 12, cooler II 13, feed tank 14, absorption tower 15, demethanizer 16, deethanizer 17. Depropanizer 19, propylene rectification / 20 and absorbent recovery tower 21;

[0092] Wherein, the oil and gas feed line is connected with the inlet of the gas-liquid separation tank 11, the top of the gas-liquid separation tank 11 is connected with the compressor 12, the light and heavy gasoline separation tower 3 in turn, and the bottom of the tank is connected with the light and heavy gasoline separation tower 5;

[0093] Light and heavy g...

Embodiment 2

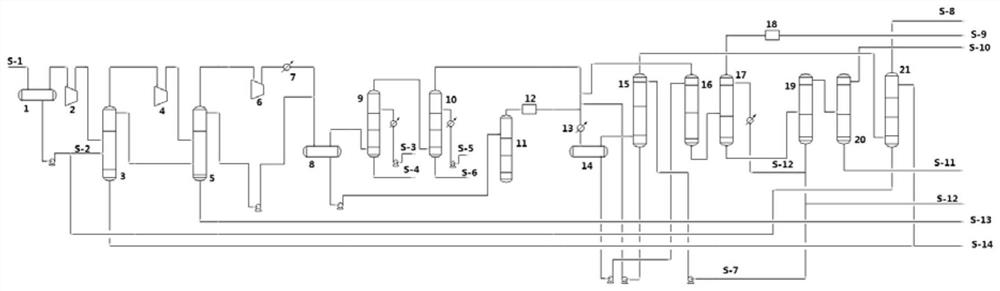

[0128] using as figure 2 The shown technological process recovers oil and gas, and the difference from Example 1 is: in this example, the part of the mixed C4 component S-15 extracted from the bottom of the depropanizer 19 is used in the deethanizer 17 as the Absorbent to separate C2 components.

[0129] Wherein, the mixed C 4 absorbent S-12 drawn from the bottom of the depropanizer 19 and sent back to the deethanizer 17 is 5000kg / h, and the recovered product compositions, flow rates and properties are shown in Tables 5 and 6 :

[0130] table 5

[0131]

[0132]

[0133] Table 6

[0134]

Embodiment 3

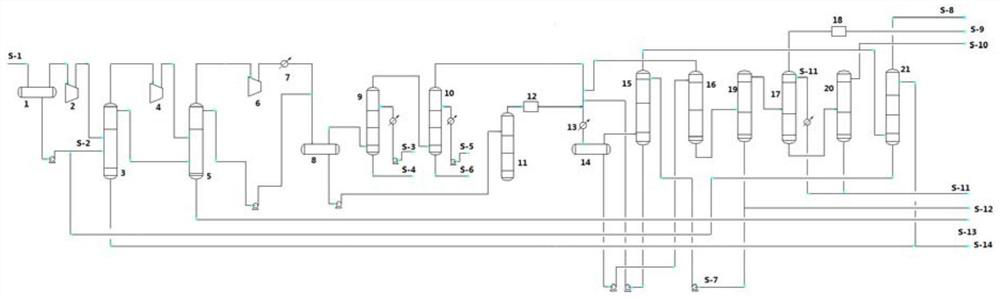

[0136] using as image 3 The shown technological process recovers oil and gas, and the difference from Example 1 is: in this example, the sequence of demethanization, depropanization, and deethanization is successively used to separate light hydrocarbons, wherein, the top of the deethanizer 17 is separated. Part of the propane taken from the bottom of the propylene rectifying tower 20 is used as the absorbent S-11 to separate the C2 component.

[0137] Wherein, the propane absorbent S-11 that is sent back to the deethanizer 17 extracted from the bottom of the propylene rectifying tower 20 is 6500kg / h, and each product composition, flow rate and property recovered are shown in Table 7, Table 8:

[0138] Table 7

[0139]

[0140]

[0141] Table 8

[0142]

[0143]

[0144] As can be seen from the data in the above table, the process of the present invention is simple, the operating conditions are moderate, the consumption of cooling energy is low, and the separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com