Method and device for recovering oil and gas

An oil-gas and gas-phase technology, which is used in the recovery of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. , the effect of efficient separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

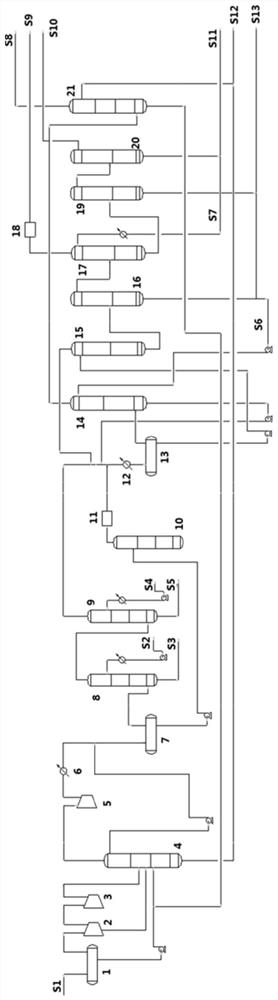

[0107] Oil and gas recovery devices include:

[0108] Oil and gas feed pipeline, gas-liquid separation tank I1, compressor I, debutanizer 4, compressor II 5, cooler Ⅰ6, gas-liquid separation tank Ⅱ7, gas-rich desulfurization tower 8, gas-rich alkali washing tower 9, liquid Hydrocarbon desulfurization tower 10, liquid hydrocarbon sweetening reactor 11, cooler II 12, feed tank 13, absorption tower 14, demethanizer 15, depropanizer I 16, deethanizer 17, impurity treatment unit 18, depropanizer Ⅱ19, propylene rectification tower 20, absorbent recovery tower 21;

[0109] Wherein, the oil-gas feed line is connected to the inlet of the gas-liquid separation tank I1, the top of the gas-liquid separation tank I1 is connected to the compressor 1 and the debutanizer 4 in turn, and the bottom of the tank is connected to the debutanizer 4;

[0110] There is a reflux tank on the top of the debutanizer 4, the top of the reflux tank is connected to the compressor II 5, the cooler Ⅰ6 and the ...

Embodiment 2

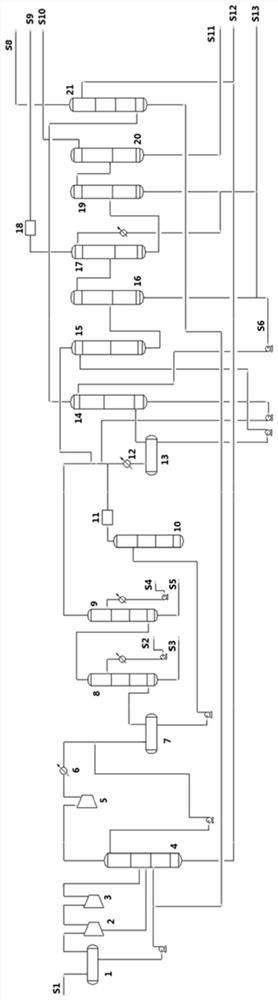

[0146] use as figure 2 The shown process flow reclaims oil and gas, and the difference from Example 1 is that in the separation step, demethanization: the liquid phase from the bottom of the feed tank 13 removes methane in the demethanizer 15, and simultaneously removes Remove a small part of C2 and components above C2, the gas phase at the top of the demethanizer 15 is cooled and then returned to the feed tank 13, and the liquid phase at the bottom of the tower is sent to the depropanizer I16;

[0147] Depropanization I: The liquid phase components from the bottom of the demethanizer 15 are separated in the depropanizer I16, and the separated top gas phase is sent to the deethanizer 17, and at least part of the bottom liquid phase is used as a mixed C4 The absorbent is sent to the absorption tower 14, and the remainder is extracted as the C4 product S13;

[0148] Deethanization: The gas phase from the top of the depropanizer I16 is separated from the C2 component in the dee...

Embodiment 3

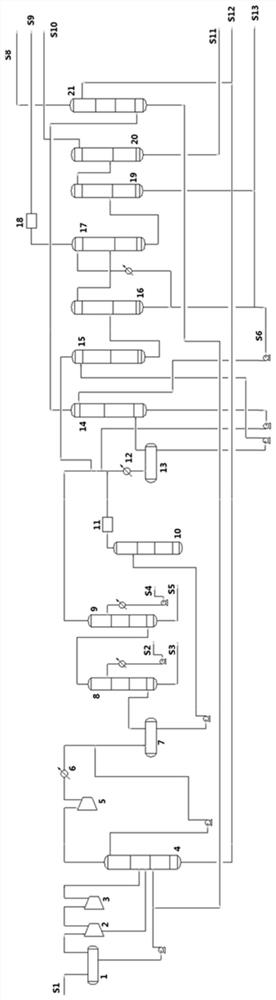

[0157] use as image 3 The shown process flow reclaims oil and gas, and the difference from Example 1 is that in the separation step, demethanization: the liquid phase from the bottom of the feed tank 13 removes methane in the demethanizer 15, and simultaneously removes Remove a small part of C2 and components above C2, the gas phase at the top of the demethanizer 15 is cooled and then returned to the feed tank 13, and the liquid phase at the bottom of the tower is sent to the depropanizer I16;

[0158] Depropanization I: The liquid phase components from the bottom of the demethanizer 15 are separated in the depropanizer I16, and the separated top gas phase is sent to the deethanizer 17, and at least part of the bottom liquid phase is used as a mixed C4 The absorbent is sent to the absorption tower 14, and a part is sent to the deethanizer 17 as a mixed C4 absorbent after cooling, and the remaining part is extracted as a C4 product S13;

[0159] Deethanization: The gas phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com