Oil and gas recovery method and device

A technology for oil, gas and gasoline, which is applied in the multi-stage series refining process, etc., can solve the problems of large circulation volume, high energy consumption, increased investment and energy consumption, etc., and achieves reduction of gasoline circulation volume, efficient separation and recovery, operation Conditioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

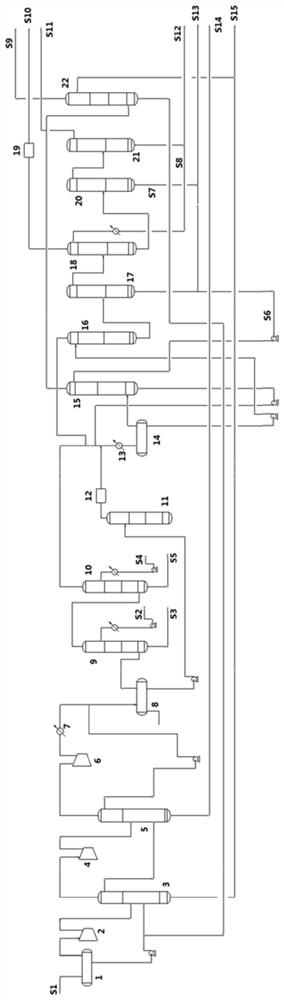

[0111]The equipment for oil and gas recovery includes:

[0112]Oil and gas feed line, gas-liquid separation tank I1, compressor I2, lightweight gasoline separation tower 3, compressor II4, light hydrocarbon-light gasoline separation tower 5, compressor III6, cooler I7, gas-liquid separation tank II8, rich gas Desulfurization tower 9, rich gas base washing tower 10, liquid hydrocarbon demonstiocarbon reactor 12, cooler II13, feed tank 14, absorption tower 15, dehydrin column 16, dehydropane column I17, deteration The alkorepin 18, the impurity treatment unit 19, the deproprin column II20, the propylene denomination 21, and the absorbent recovery tower 22;

[0113]Among them, the oil and gas feed line is connected to the gas-liquid separation tank I1 inlet, and the gas-liquid separation tank I1 can be sequentially connected to the compressor I2, the lightweight gasoline separation tower 3, and the bottom of the tank is connected to the lightweight gasoline separation tower;

[0114]Lightweight...

Embodiment 2

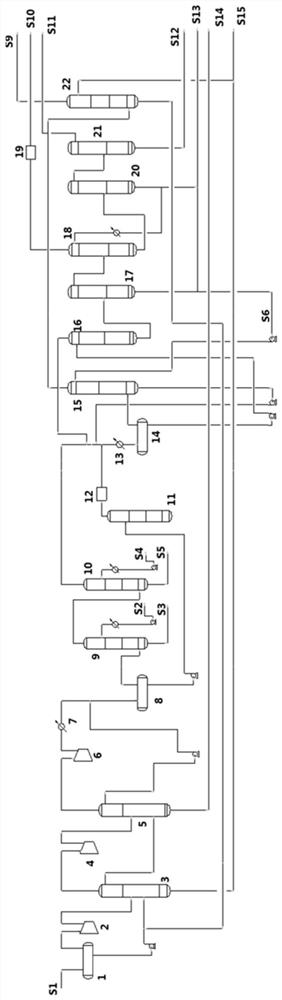

[0152]Usefigure 2 The process flow shown is recovered in oil and gas, and the difference in Example 1 is in: in the separation step,

[0153]Demethyl: The liquid phase from the bottom of the feed can remove methane in the demethane tower 16, while removing the components of less C2 and C2 or more, the demetanne tower 16 tower is closed and returned. Tank 14, the bottom of the tower is delivered to the delinpropylene column I17;

[0154]Demnophythane I: Liquid phase components from the bottom of the demethhane tower 16 were separated in the delxtin column I17, separated from the top of the tower to the dethyl hem 18, and part of the bottom liquid phase was absorbed as mixed C4 The agent S6 is sent to the absorption tower 15, and the remainder is eliminated as the C4 product S13;

[0155]Diene: The gas phase from the top of the dehydrophane tower I17 is separated from the chipped C4 in the dethyl column 18 to isolate the C2 component, and the separated column is mixed C2 components after impur...

Embodiment 3

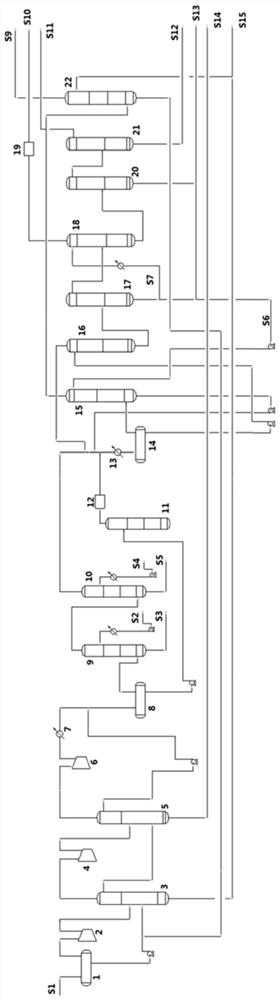

[0165]Useimage 3 The process flow shown is recovered in oil and gas, and the difference in Example 1 is in: in the separation step,

[0166]Demethyl: The liquid phase from the bottom of the feed can remove methane in the demethane tower 16, while removing the components of less C2 and C2 or more, the demetanne tower 16 tower is closed and returned. Tank 14, the bottom of the tower is delivered to the delinpropylene column I17;

[0167]Demnophythane I: Liquid phase components from the bottom of the demethhane tower 16 were separated in the delxtin column I17, separated from the top of the tower to the dethyl hem 18, and part of the bottom liquid phase was absorbed as mixed C4 The agent S6 is sent to the absorption tower 15, and a portion is sent as a mixed C4 absorbent to the dehydrated tower 18 after cooling; the remainder is obtained as the C4 product S13;

[0168]Diene: The gas phase from the top of the dehydrophane tower I17 is separated from the chipped C4 in the dethyl column 18 to isol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com