Asymmetrically synchronous reluctance motor rotor lamination

A synchronous reluctance motor, rotor punching technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electrical components, etc., can solve the problems of large electromagnetic noise and electromagnetic vibration, large torque pulsation of synchronous reluctance motor, etc. The effect of improving the quality of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

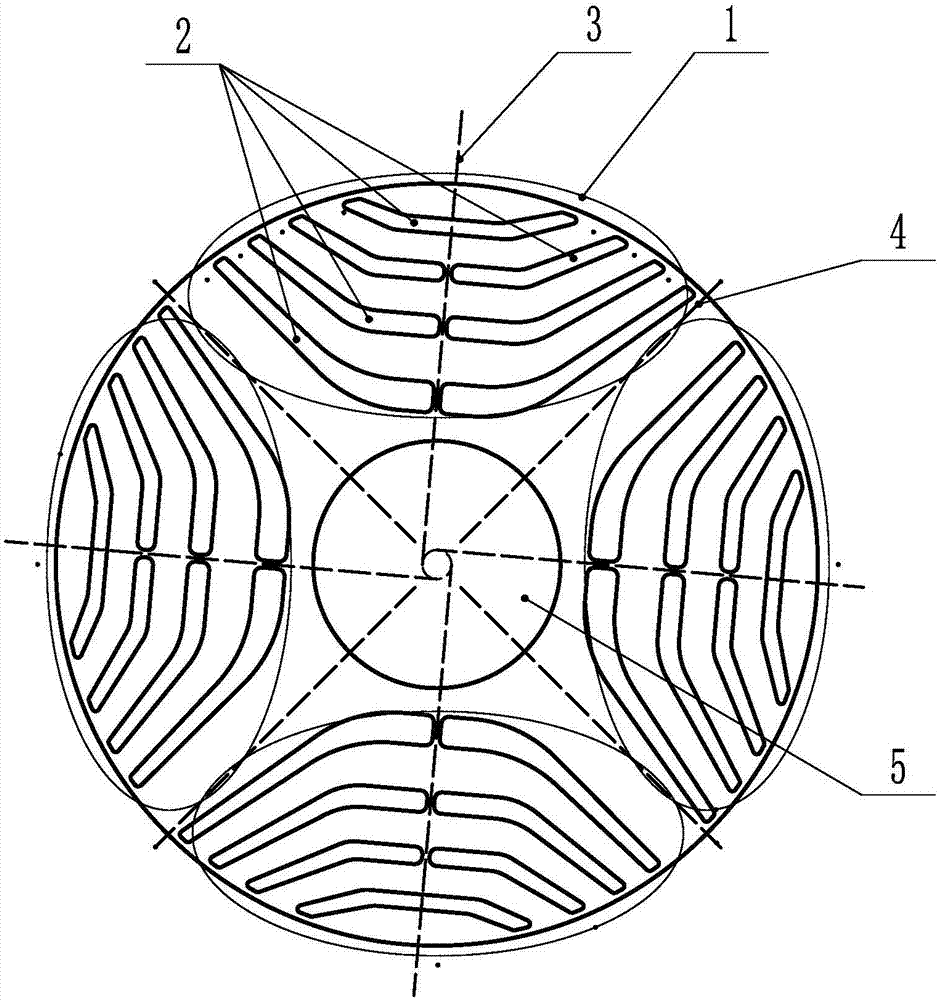

[0026] Such as figure 1 As shown, an asymmetric synchronous reluctance motor rotor stamping, the rotor stamping has 4 sets of hole slots, the area where each set of hole slots is located forms a magnetic pole 1, a total of 4 magnetic poles 1 are formed, and the hole slots are reluctance slots 2 , the center of the rotor punch has a shaft hole 5, the geometric center line of the magnetic pole 1 is the magnetic pole axis 3, the symmetrical axis of the two adjacent magnetic pole axes 3 is the non-magnetic pole axis 4, the rotor punch is an asymmetric structure, each magnetic pole The reluctance slot 2 of 1 is asymmetrical with respect to the magnetic pole axis 3. The reluctance slot 2 includes an outer slot located outside the magnetic pole 1, and three inner slots located between the outer slot and the shaft hole 5. Both the outer slot and the inner slot include The flat groove located in the middle of the magnetic pole 1 and the left and right inclined grooves connected with th...

example 2

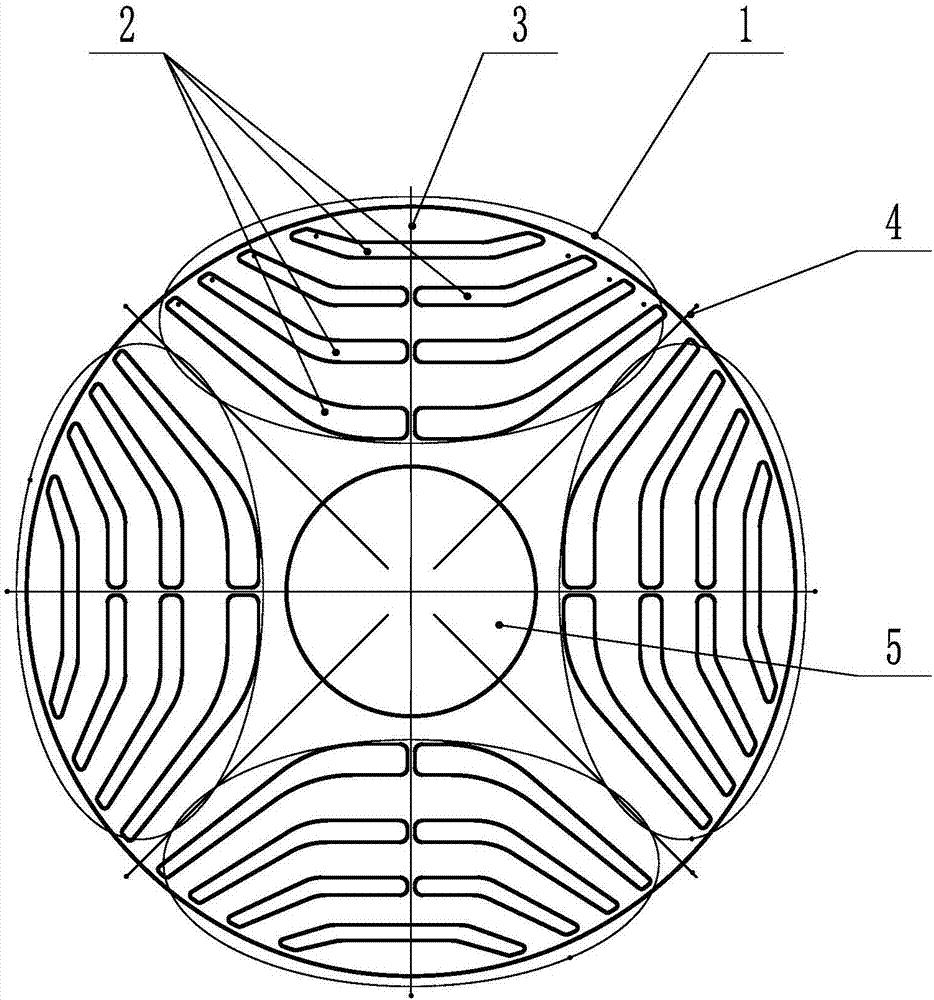

[0029] Such as figure 2 As shown, the difference from the first example above is that for an asymmetric synchronous reluctance motor rotor punching, two adjacent magnetic poles 1 are symmetrical about the non-magnetic pole axis 4 .

example 3

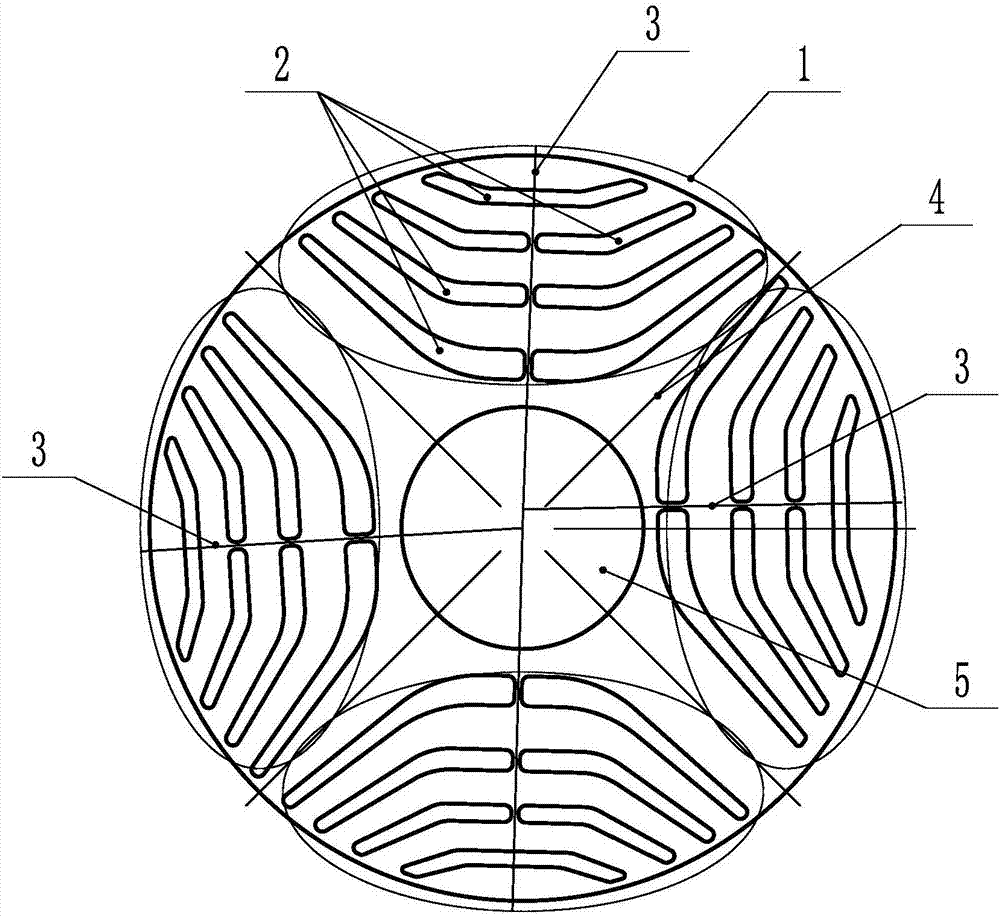

[0031] Such as image 3 As shown, the difference from the first example above is that for an asymmetric synchronous reluctance motor rotor punching, the angles between two adjacent magnetic pole axes 3 are not equal; the adjacent two non-magnetic pole axes 4 The angles between them are not equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com