A kind of fpc reinforcing board production process and its products

A production process and reinforcement board technology, which is applied to bendable/stretchable circuit parts, printed circuits, printed circuit parts, etc., can solve the problem of tight reinforcement board, excessive protective film area, stretching Poor ability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

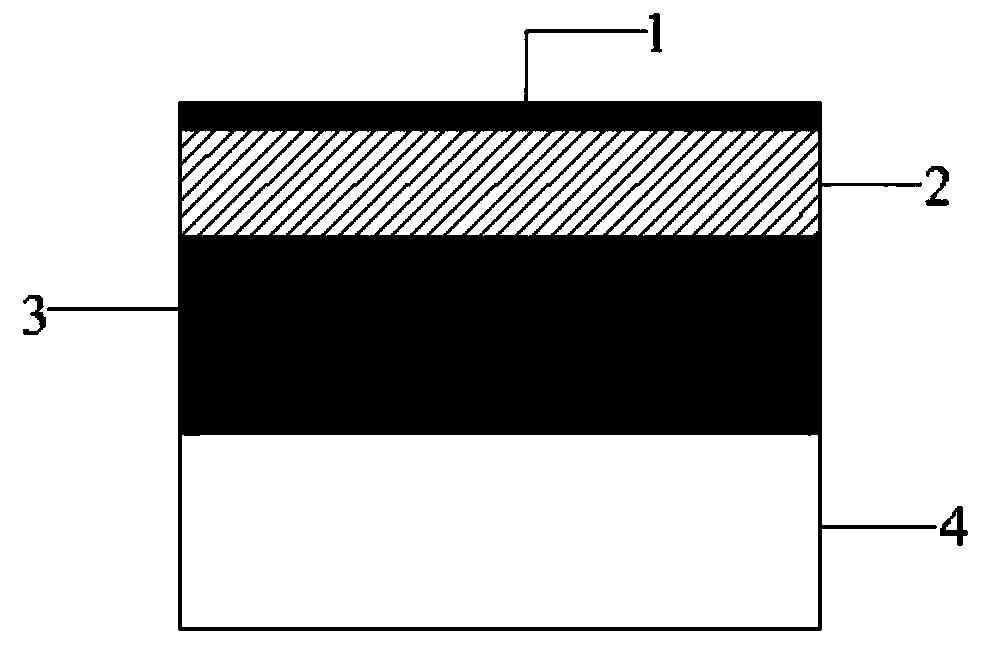

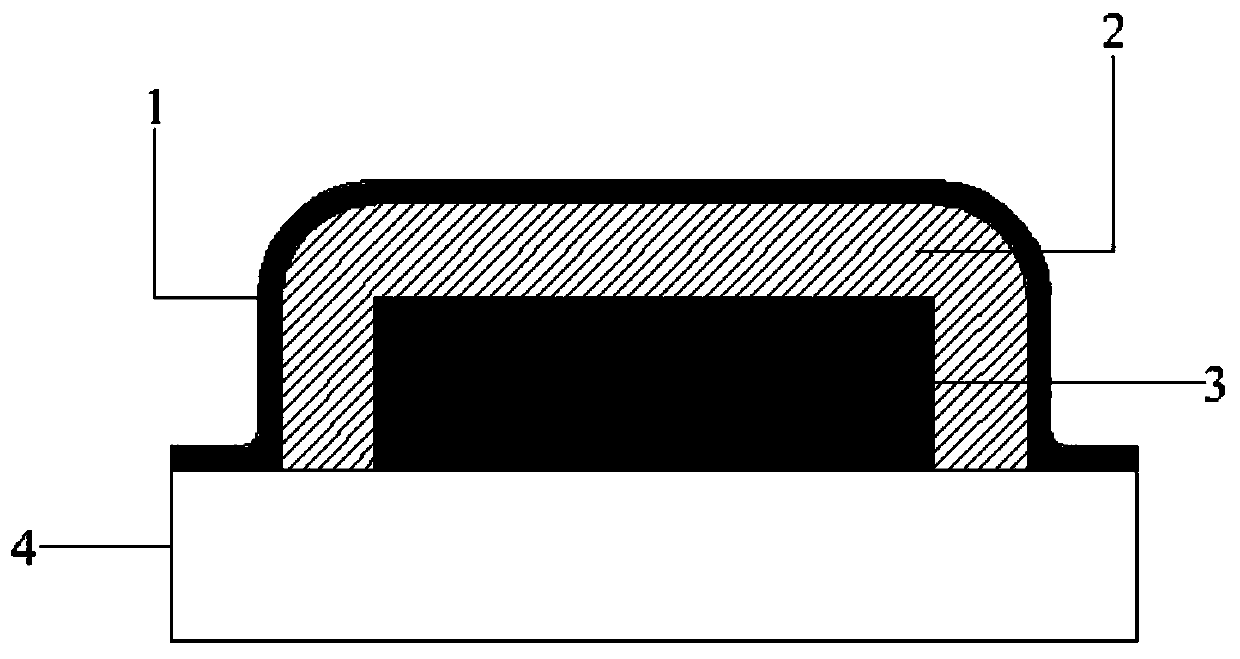

[0028] Such as figure 1 As shown, the FPC reinforcement board is composed of a protective film, a reinforcement board 3 and an FPC board 4, specifically, the reinforcement board 3 is pasted on the FPC board 4, and then a protective film is pasted on the reinforcement board 3, wherein the protection The film consists of a surface layer 1 and an adhesive layer 2. In actual production, it is necessary to make the protective film tightly wrap the reinforcing plate 3. After the protective film is pressed, the ideal effect should be as follows figure 2 shown.

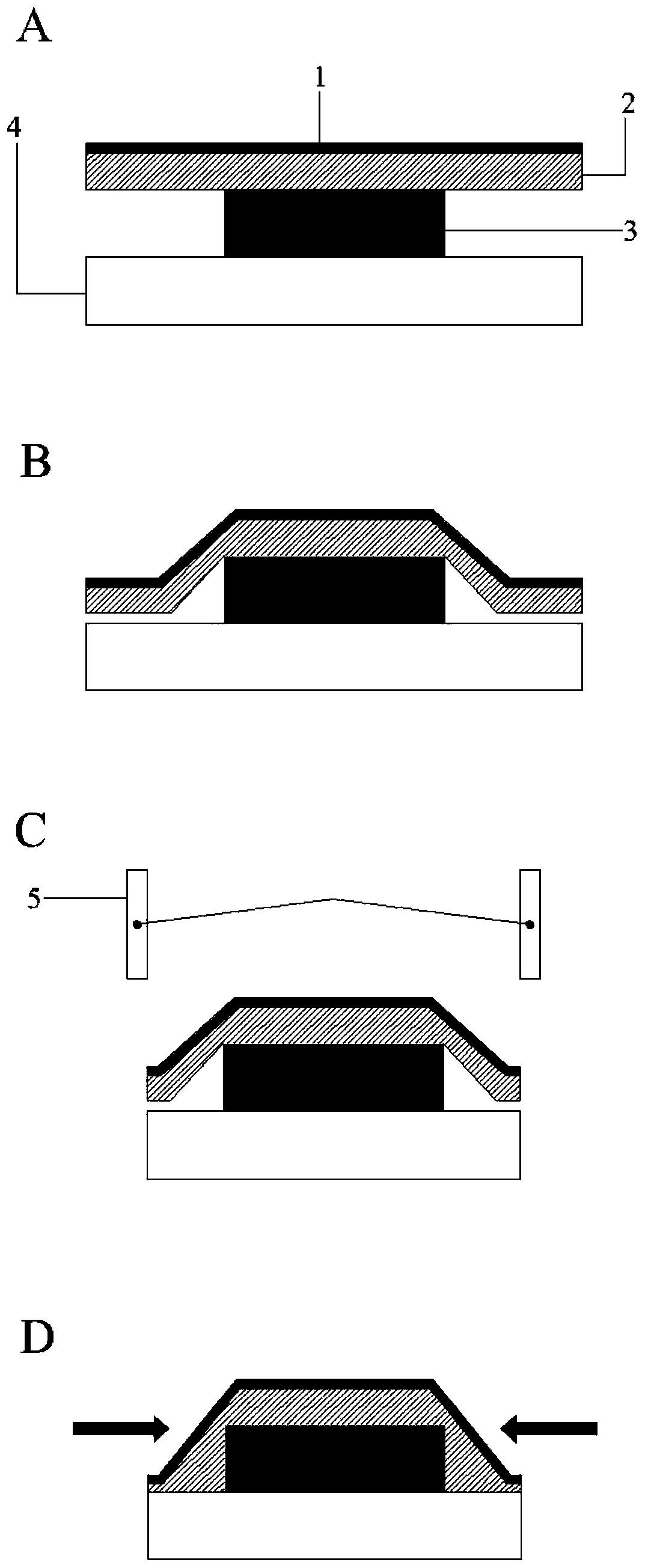

[0029] In order to achieve the technical effect that the protective film can tightly wrap the reinforcing plate 3, a production process of the FPC reinforcing plate of the present invention provides a specific implementation mode, the schematic diagram of the steps is as follows image 3 shown. in, image 3 Corresponding content of A: Paste the reinforcing plate 3 on the FPC board 4, and put a protective film on the rein...

Embodiment 2

[0033] Figure 5 It shows that the steel plate 7 is pasted on the FPC board 4, Image 6 PI reinforced protective film 8 is shown. The FPC reinforcing plate that adopts the FPC reinforcing plate production technology provided by the invention to make is as Figure 7 As shown, it includes FPC board 4 , steel plate 7 and PI reinforced protective film 8 . Wherein, the thickness of the steel plate 7 is 0.2 mm, and the thickness of the PI reinforced protective film 8 is 68 μm. To make the FPC reinforced board, first paste the steel plate 7 on the FPC board 4, then falsely paste the PI reinforced protective film 8 on the steel plate 7, pre-press the PI reinforced protective film 8, wrap the PI reinforced protective film 8 with the steel plate 7 The shape of the FPC plate is extruded, and the FPC reinforced plate is punched using the punching die 5. Up to this point, the PI reinforced protective film 8 has been separated from the surface of the FPC plate 4, and finally the two side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com