Internal cooling device and method of steel pipe on-line cooling

A technology of cooling device and steel pipe, applied in workpiece cooling device, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of large difference in internal and external cooling rate, insufficient strength margin, uneven structure, etc. The consistency of the organization, the improvement of the comprehensive mechanical properties, the effect of expanding the specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

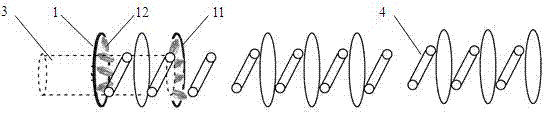

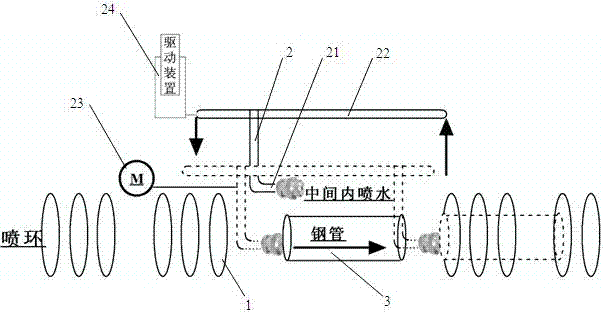

[0024] see figure 1 with figure 2 , an internal cooling device for on-line cooling of steel pipes, which is a part of the on-line spray ring cooling device for steel pipes. The steel pipe online spray ring cooling device includes multiple groups of water spray rings, each group of water spray rings 1 is composed of several water spray ring bodies 11 arranged in front and back, and several nozzles 12 are installed on the water spray ring body 11 along the periphery of the ring , multiple groups of water spray rings 1 are fixedly installed on the cooling roller table 4 line, and spray water to cool the steel pipe 3 placed on the cooling roller table line. Most of the water spray rings in the online spray ring cooling device for steel pipes directly spray water to cool the outer surface of the steel pipe, and some of the water spray rings spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com