Mold for constructing sandwich structure prefabricated wall panel and molding method

A technology of prefabricated wall panels and sandwiches, applied in the direction of moulds, manufacturing tools, ceramic molding machines, etc., can solve the problems of high work intensity, low work efficiency, damage to formwork, etc., to save concrete materials, improve production efficiency, and mold structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

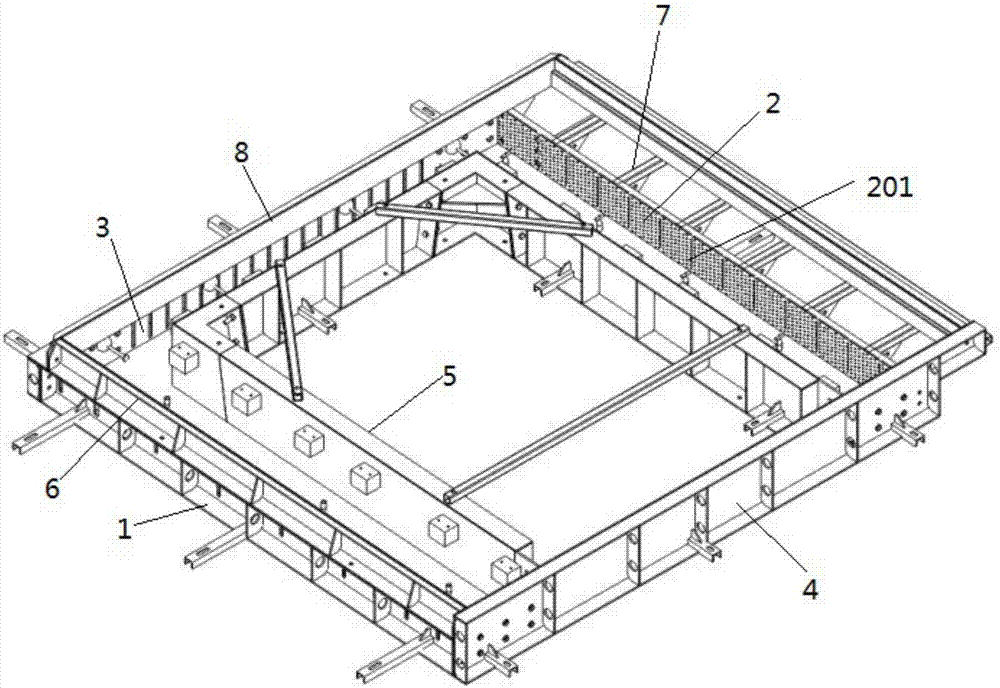

[0037] The following will refer to the accompanying drawings from 1 to Figure 5 The present invention will be described in detail in combination with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

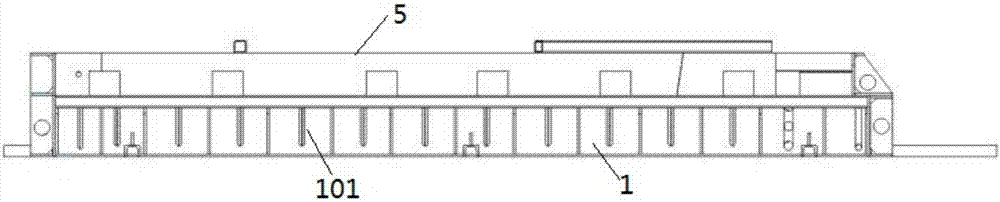

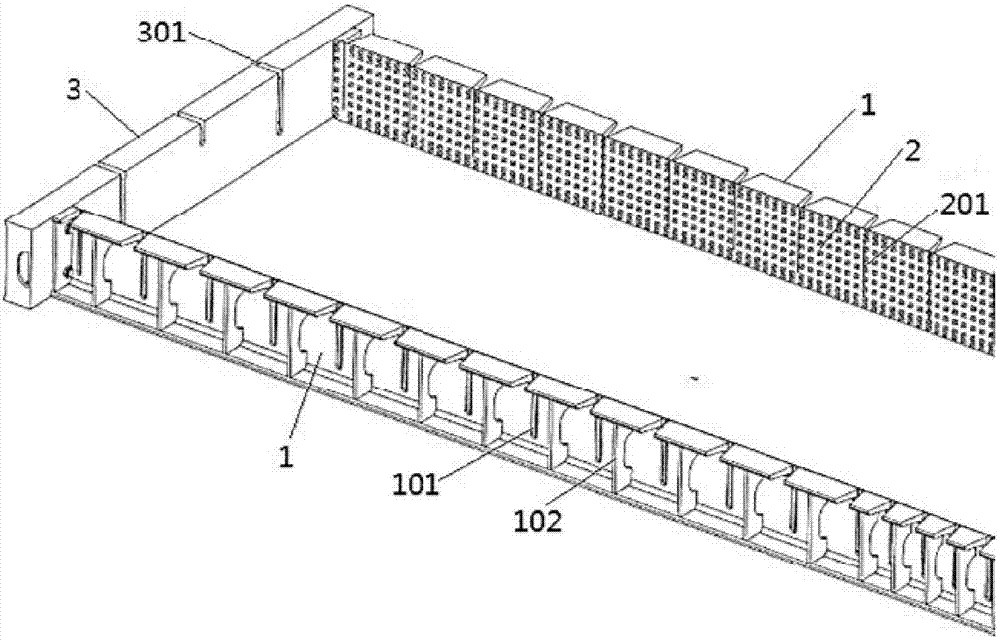

[0038] Such as figure 1 and figure 2 As shown, the mold for constructing the sandwich structure prefabricated wallboard includes the inner sidewall 1 and the first outer sidewall 6 detachably fixed on the top of the inner sidewall by bolts, and each outlet of the inner sidewall 1 The positions of the ribs are respectively provided with first accommodating grooves 101 for steel bars to pass through. The tops of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com