Shock-absorption noise-reduction structure in ship cabin

A technology for noise reduction and shipbuilding, applied in the field of interior decoration of ships, can solve problems such as inability to effectively reduce equipment vibration and noise, insignificant effects, noise pollution in ship cabins, etc., to eliminate vibration and noise, and reduce the source of noise and vibration. , enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

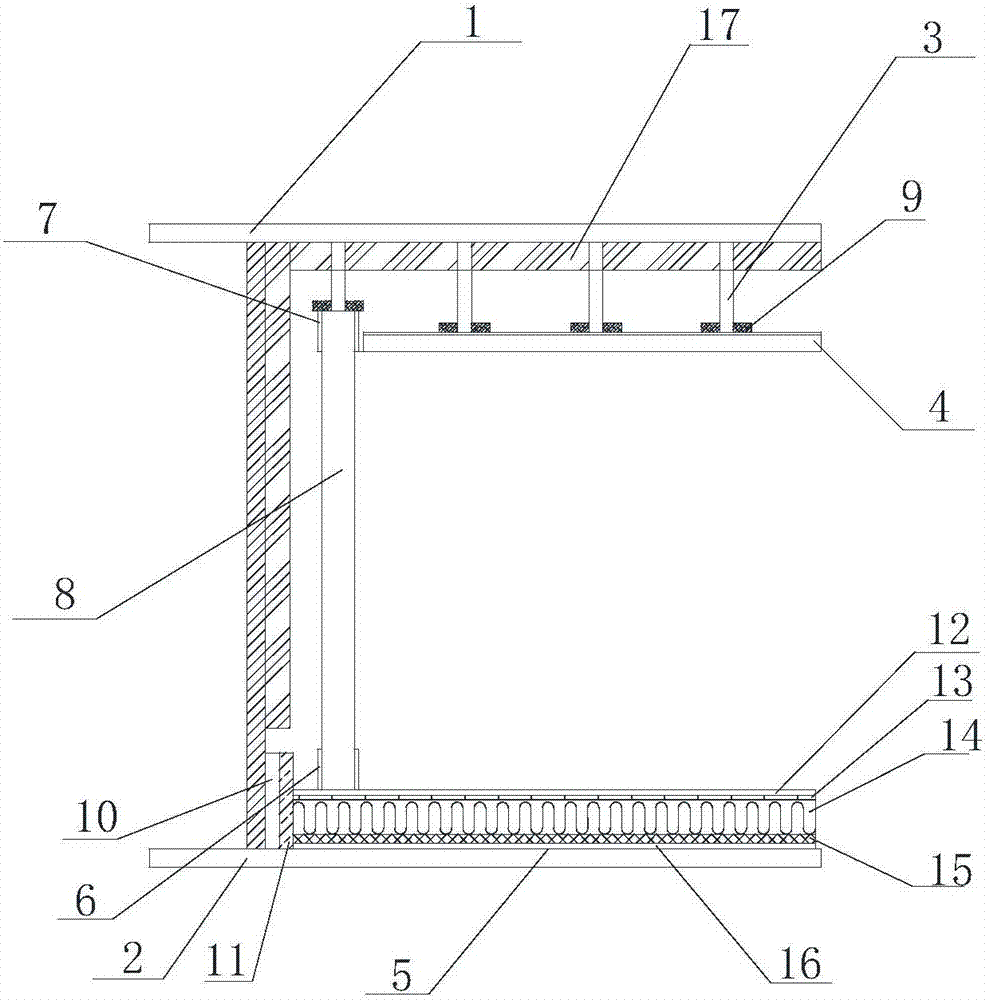

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, a shock-absorbing and noise-reducing structure in a ship cabin of the present invention includes an upper deck 1 and a lower deck 2. The upper deck 1 is provided with several elastic pendants 3, and the lower ends of the elastic pendants 3 are connected to the ceiling 4. , the lower deck 2 is provided with a floor 5, the floor 5 is provided with a bottom groove 6, and one end of the ceiling 4 is provided with a top groove 7 opposite to the bottom groove 6, and the top groove 7 and the bottom groove 6 A bulkhead plate 8 is arranged between them, and sound-insulating and shock-absorbing pads 9 are symmetrically provided at both ends of the bottom of the elastic pendant 3, and a support plate 10 is provided at the end of the floor 5 close to the bulkhead plate 8, and the support plate 10 and A sound insulation mat 11 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com