Reverse buckling type double-U clamping type submersible water impeller

A submersible flow propeller and inverted technology, applied in water aeration, underwater operation equipment, chemical instruments and methods, etc., can solve the problem of vibration and short life, unable to fix and clamp flow propeller, flow propeller It is easy to vibrate and noise and other problems, so as to achieve the effect of eliminating vibration and noise and making the equipment run stably and reliably for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

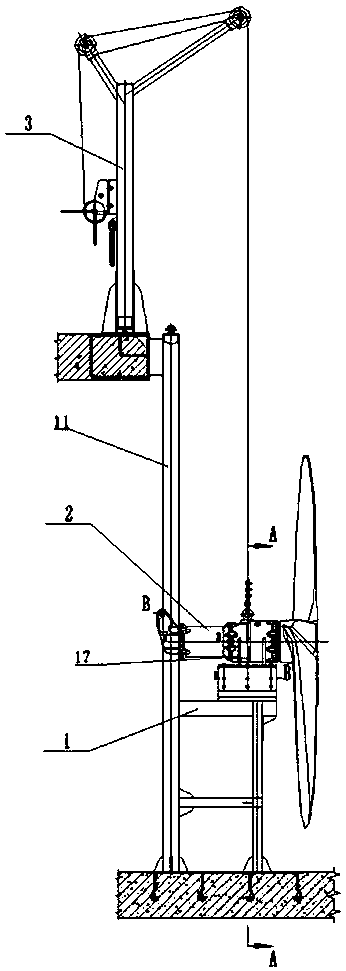

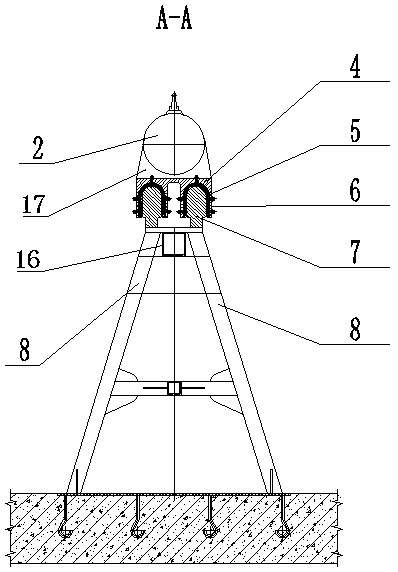

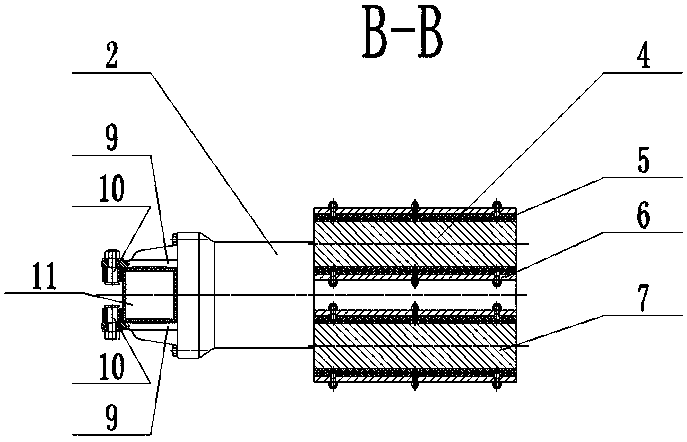

[0028] like figure 1 , 2 , 3, 4, 5, 7, 8, 8, 10, 11, 12, 13, the upper part of the underwater guide rail mounting seat 11 is fixedly connected to the concrete on the pool surface, and the lower part is fixedly connected to the concrete at the bottom of the pool. The surface is supported on the bottom of the pool in an indomitable state, and is firmly fixed between the pool surface and the bottom of the pool. The underwater guide rail mounting seat 1 is provided with two inverted U-shaped supporting tenons 7, and the inverted U-shaped supporting tenons 7 Vertical arrangement, straight and vertical, in the state of double bars of sports equipment, the two inverted U-shaped support tenon blocks 7 of the double bar structure are connected with the cross bar in a certain size structure, and the cross bar is used as the positioning reference. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com