Conveying belt sweeping device

A technology for cleaning devices and conveyor belts, which is applied in the field of machinery, can solve problems such as unsatisfactory cleaning effects, and achieve the effects of easy implementation, reduced damage, and good transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

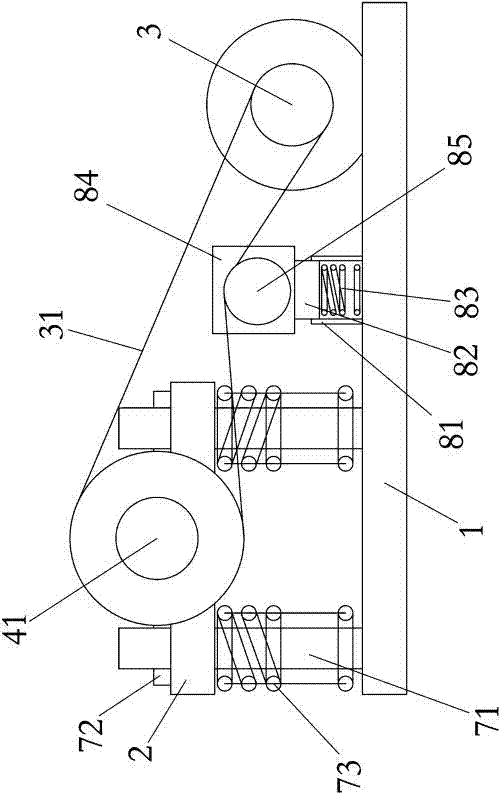

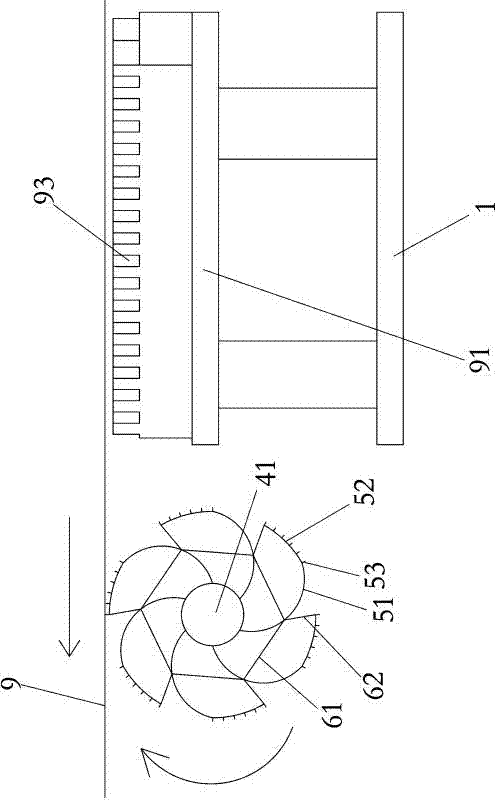

[0014] Example: such as Figure 1-3 As shown, a conveyor belt cleaning device includes a base 1, a pre-treatment structure located on the base 1, two floating seats 2 provided on the base 1, scraper assemblies that are respectively connected to the corresponding floating seats 2 in rotation at both ends, The driving device 3 is connected with the scraper assembly; the driving device 3 is a motor.

[0015] The scraper assembly includes two ends that are rotatably connected to the rotating shaft 41 corresponding to the floating seat 2, and at least three scraper structures that are evenly distributed along the circumferential direction of the rotating shaft 41 and fixedly connected to the rotating shaft 41; this embodiment has six scraper structures.

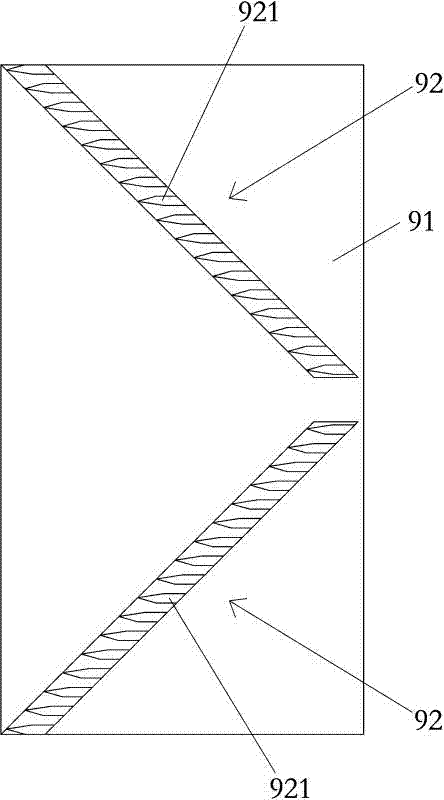

[0016] The scraper structure includes a support plate 51 fixedly connected to the rotating shaft 41 with an arc-shaped cross section, a mounting plate 52 fixedly connected to the support plate 51 with an arc-shaped cross-section, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com