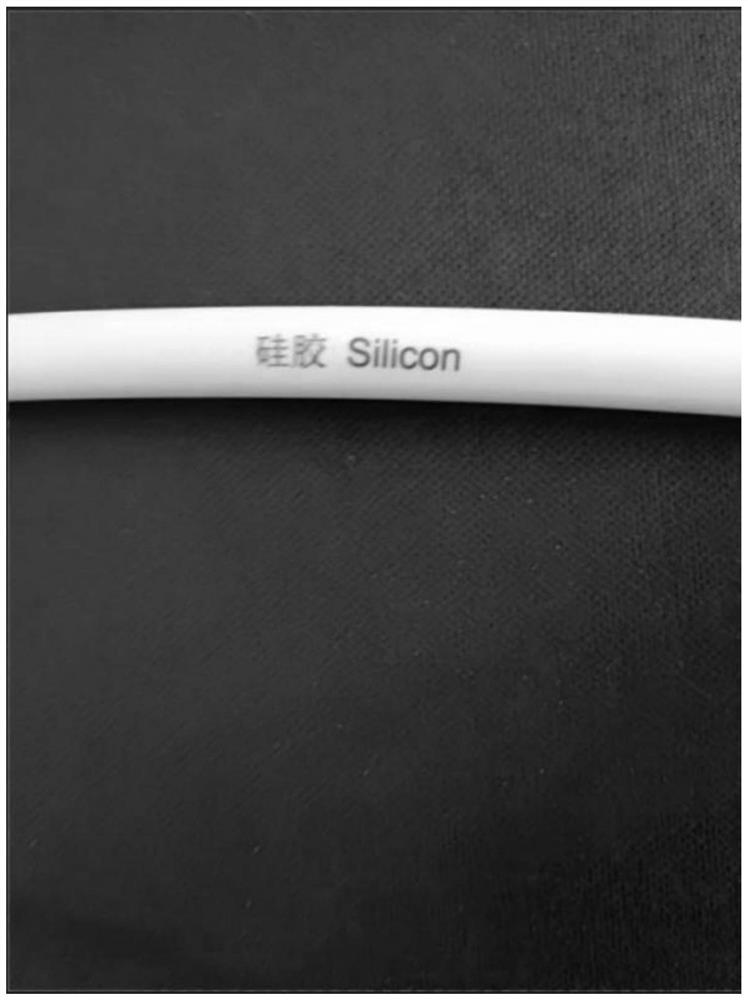

A kind of silicone rubber compound suitable for laser marking on silicone rubber wire and cable and its preparation method

A wire and cable, laser marking technology, applied to rubber insulators, organic insulators, etc., to achieve strong three-dimensional effect, clear fonts, and unique craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]The silicone rubber compound suitable for laser marking on silicone rubber wires and cables of this embodiment is made of raw materials with the following weights: 100 kg of methyl vinyl silicone rubber, 40 kg of silicon dioxide, 10 kg of hydroxy silicone oil, and dimethyl two Ethoxysilane 1kg, stearic acid 0.6kg, vinyltrimethoxysilane 0.5kg, titanium dioxide conductive powder 1.5kg and bis(2,4-dichlorobenzoyl) 0.8kg. Wherein, the polymerization degree of the hydroxy silicone oil is 4, and the viscosity is 31mm2 / S, the hydroxyl content is 9.1%, the particle size of the titanium dioxide conductive powder is 5-10μm, the color is white and gray, heat resistance ≥280℃, electrical resistivity<50Ω·cm.

[0046]The method for preparing a silicone rubber compound suitable for laser marking on silicone rubber wires and cables of this embodiment includes the following steps:

[0047](1) Take the following raw materials: methyl vinyl silicone rubber 100 kg, silica 40 kg, hydroxy silicone oil 10...

Embodiment 2

[0057]The silicone rubber compound suitable for laser marking on silicone rubber wires and cables of this embodiment is made of raw materials of the following weights: 100 kg of methyl vinyl silicone rubber, 55 kg of silicon dioxide, 6 kg of hydroxy silicone oil, and dimethyl two 3kg of ethoxysilane, 0.5kg of stearic acid, 1.8kg of vinyl triethoxysilane, 0.8kg of titanium dioxide conductive powder and 1.2kg of bis(2,4-dichlorobenzoyl) peroxide. Wherein, the polymerization degree of the hydroxy silicone oil is 4, and the viscosity is 31mm2 / S, the hydroxyl content is 9.1%, the particle size of the titanium dioxide conductive powder is 5-10μm, the color is white and gray, heat resistance ≥280℃, electrical resistivity<50Ω·cm.

[0058]The method for preparing a silicone rubber compound suitable for laser marking on silicone rubber wires and cables of this embodiment includes the following steps:

[0059](1) Take the following raw materials: 100kg of methyl vinyl silicone rubber, 55kg of silica...

Embodiment 3

[0069]The silicone rubber compound suitable for laser marking on silicone rubber wires and cables of this embodiment is made of raw materials of the following weight kg: 100 kg of methyl vinyl silicone rubber, 60 kg of silicon dioxide, 5 kg of hydroxy silicone oil, and dimethyl Diethoxysilane 5kg, stearic acid 0.3kg, vinyl triethoxysilane 3kg, titanium dioxide conductive powder 0.2kg and bis(2,4-dichlorobenzoyl) 1.5kg. Wherein, the polymerization degree of the hydroxy silicone oil is 4, and the viscosity is 31mm2 / S, the hydroxyl content is 9.1%, the particle size of the titanium dioxide conductive powder is 5-10μm, the color is white and gray, heat resistance ≥280℃, electrical resistivity<50Ω·cm.

[0070]The method for preparing a silicone rubber compound suitable for laser marking on silicone rubber wires and cables of this embodiment includes the following steps:

[0071](1) Take the following raw materials: phenyl vinyl silicone rubber 100kg, silica 60kg, hydroxy silicone oil 5kg, dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com