Diameter measurement device based on cut ruler

A technology of diameter measurement and scissors, which is applied in the field of diameter measuring devices based on scissors, can solve the problems of high requirements on the operating environment of the measuring object, limited measuring diameter range, inconvenient carrying and measuring, etc., and is conducive to remote data collection. , easy-to-implement, cleverly structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

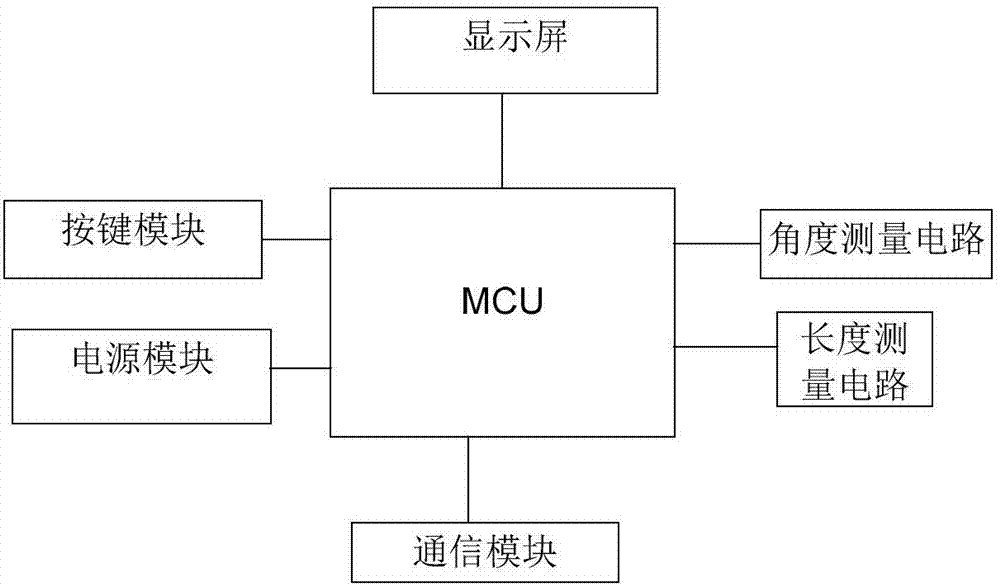

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

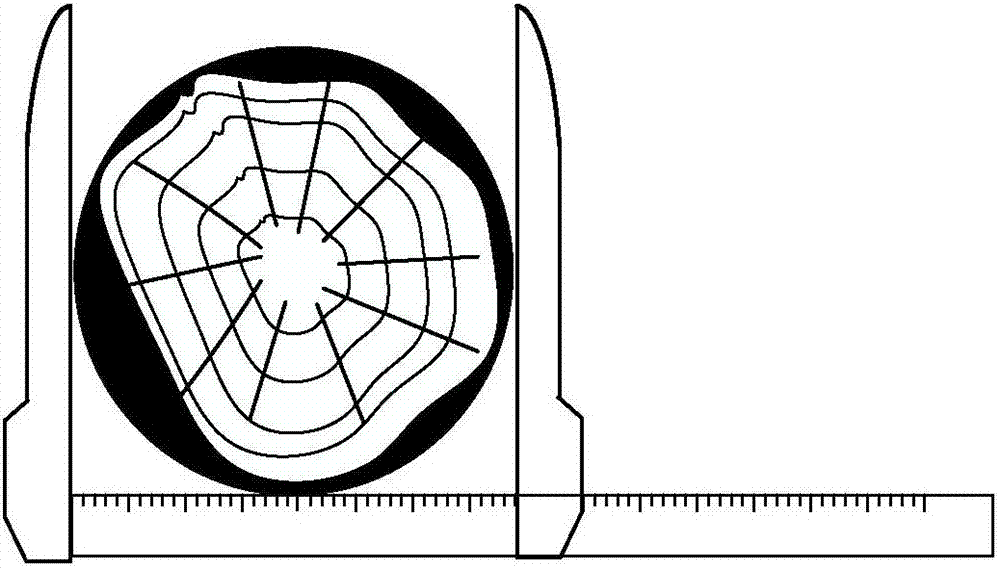

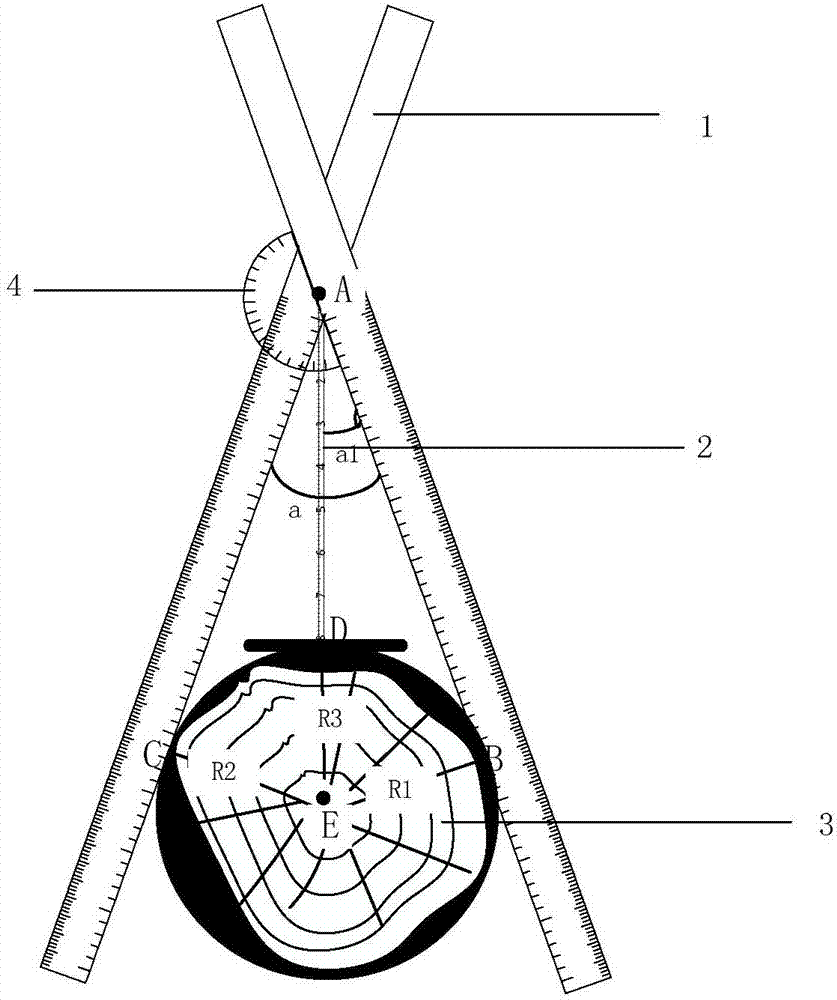

[0070] Embodiment 1: as figure 2 , a diameter measuring device based on scissors, including scissors 1, a straightedge and a protractor 4; the first end of the straightedge is connected with the hinge point A of the scissors, and the second end of the straightedge is used to connect with the measured Object (such as trunk 3) surface contact; The measured object is cylindrical or cylindrical;

[0071] Open the two arms of the scissors to clamp the measured object, and the second end of the ruler is in contact with the surface of the measured object;

[0072] The diameter Φ of the measured object is calculated based on the length of the ruler and the opening angle of the scissors measured by the protractor.

[0073] Described ruler is T-square 2.

[0074] The diameter of the measured object Φ=2R=2*L0*sin(a / 2) / [1-sin(a / 2)];

[0075] Where L0 is the length of the straightedge from the hinge point to the second end; generally the length of the straightedge is a fixed length.

...

Embodiment 2

[0080] Such as Figure 2-5 , a diameter measuring device based on scissors, comprising scissors (1), a ruler and a protractor (4); the first end of the ruler is connected with the hinge point A of the ruler, and the second end of the ruler is connected with In contact with the surface of the measured object; the measured object is cylindrical or cylindrical;

[0081] Open the two arms of the scissors to clamp the measured object, and the second end of the ruler is in contact with the surface of the measured object;

[0082] The diameter Φ of the measured object is calculated based on the length of the ruler and the opening angle of the scissors measured by the protractor.

[0083] Described ruler is T-square (2).

[0084] The diameter of the measured object Φ=2*(R1+R2+R3) / 3;

[0085] in:

[0086] R1 is the radius corresponding to the contact point D between the second end of the ruler and the surface of the measured object;

[0087] R2 is the radius corresponding to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com