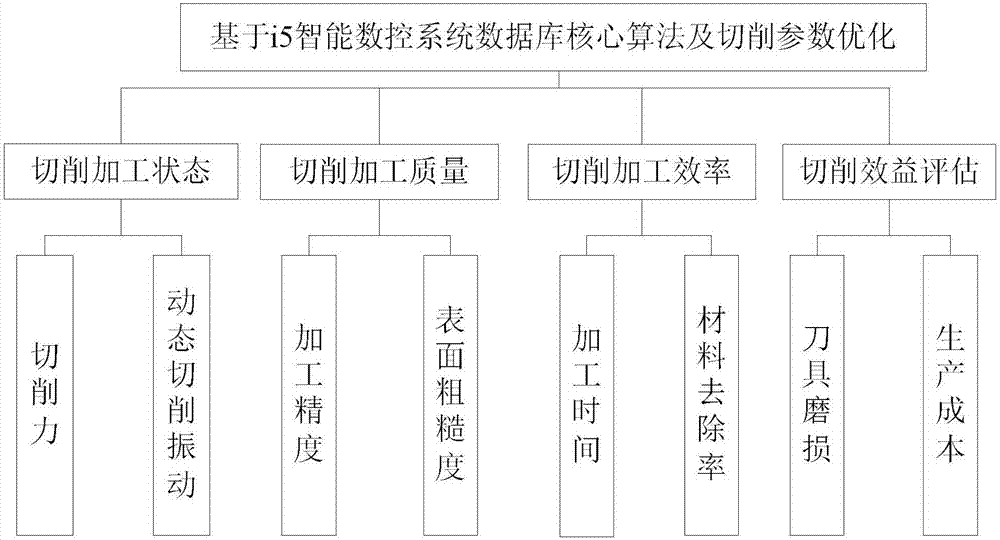

Multi-target cutting data generation algorithm and cutting parameter optimization method of numerical control machine tool

A technology of cutting data and generating algorithms, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of not strong comprehensiveness of cutting database algorithms, unfavorable machine tool processing efficiency, and less pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0146] 1. Multi-objective cutting data generation algorithm and cutting parameter optimization method of CNC machine tools, the steps are:

[0147] 1. Generate data algorithm:

[0148] 1) Machine tool cutting efficiency: it is the pure cutting time of CNC lathes and turning center parts for turning applications, which is the volume of material that can be removed per unit time. The calculation algorithm of machine tool cutting efficiency is shown in formula (1):

[0149]

[0150] In the formula, a p ——cutting depth, mm;

[0151] n——spindle speed, r / min;

[0152] f r ——Feed per revolution, mm / r;

[0153] D. e ——Workpiece effective diameter, mm, D e =(D i +D o ) / 2;

[0154] The power P and torque T of the spindle motor are shown by formula (2) and formula (3) respectively:

[0155]

[0156] In the formula, P c ——cutting power, kW, P c =Tn / 9549;

[0157] η——efficiency;

[0158] P 0 ——motor power, kW;

[0159] T——spindle torque, Nm;

[0160]

[0161] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com