Optimization method and system of fuel gas system based on heat value balance

An optimization method, fuel gas technology, applied in the direction of instruments, data processing applications, forecasting, etc., can solve problems such as low efficiency, achieve the effect of improving stability, strong executable, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

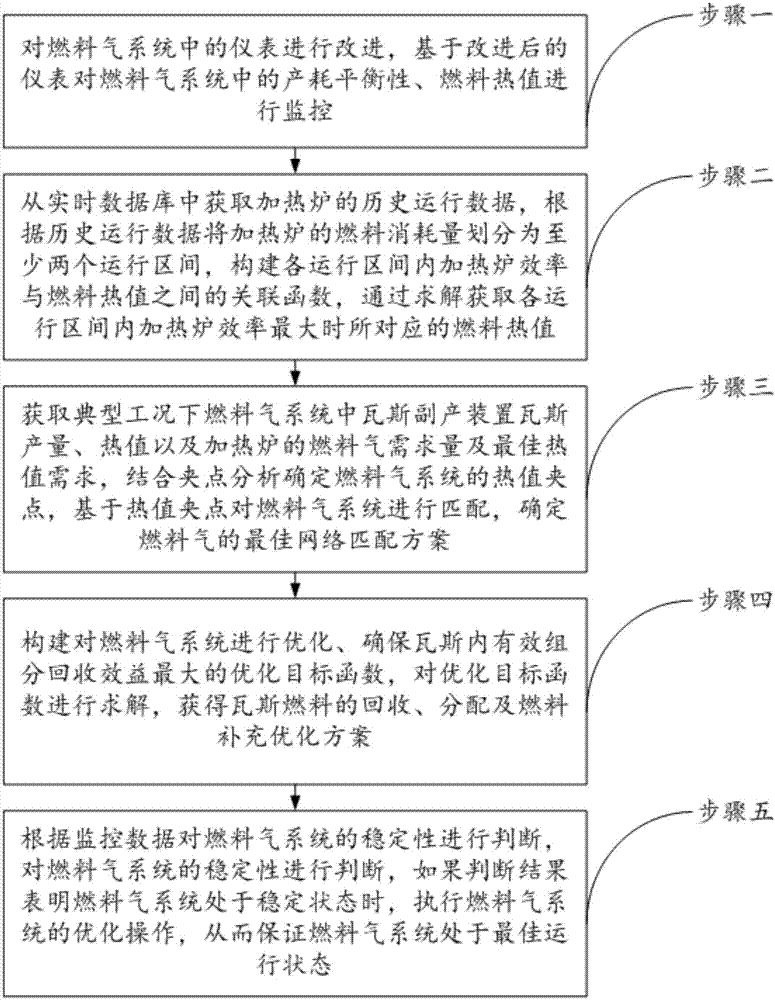

[0054] The optimization method of the fuel gas system based on calorific value balance provided by the present invention, such as figure 1 As shown, the method specifically includes:

[0055] Step 1. Improve the instruments in the fuel gas system, and monitor the production-consumption balance and fuel calorific value in the fuel gas system based on the improved instruments;

[0056] Step 2. Obtain the historical operating data of the heating furnace from the real-time database, divide the fuel consumption of the heating furnace into at least two operating intervals according to the historical operating data, and construct the relationship between the efficiency of the heating furnace and the calorific value of the fuel in each operating interval function, and obtain the calorific value of the fuel corresponding to the maximum efficiency of the heating furnace in each operating interval by solving;

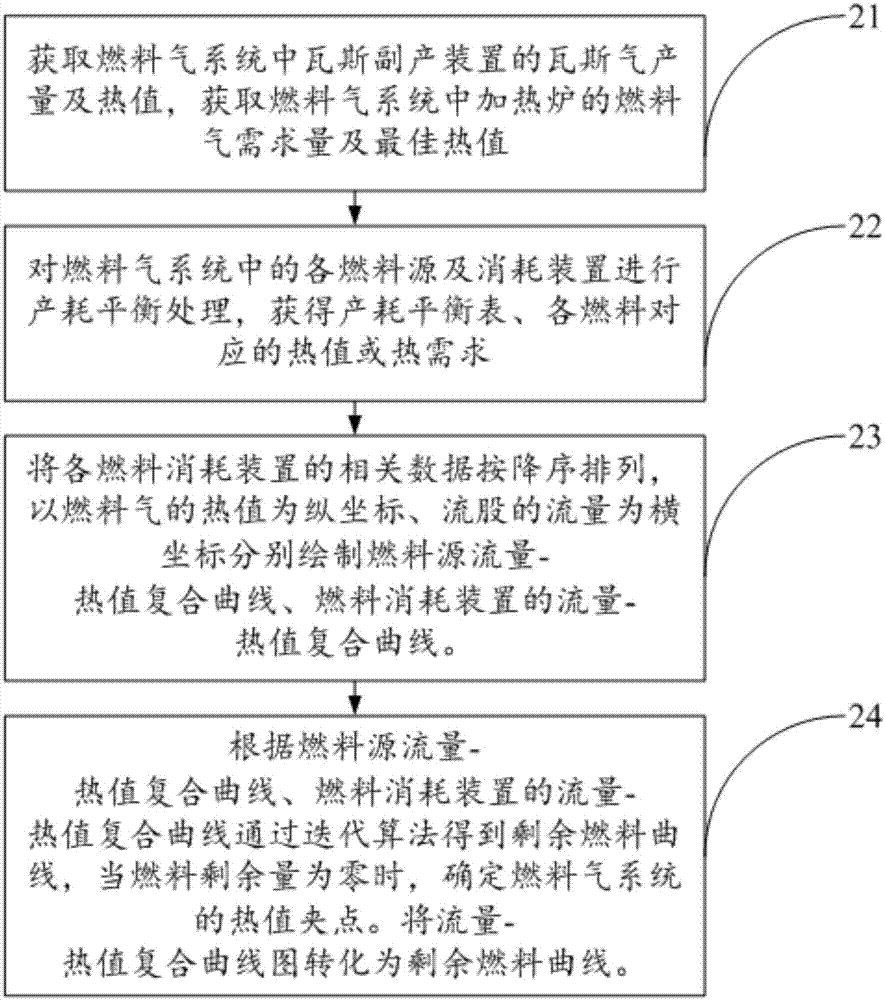

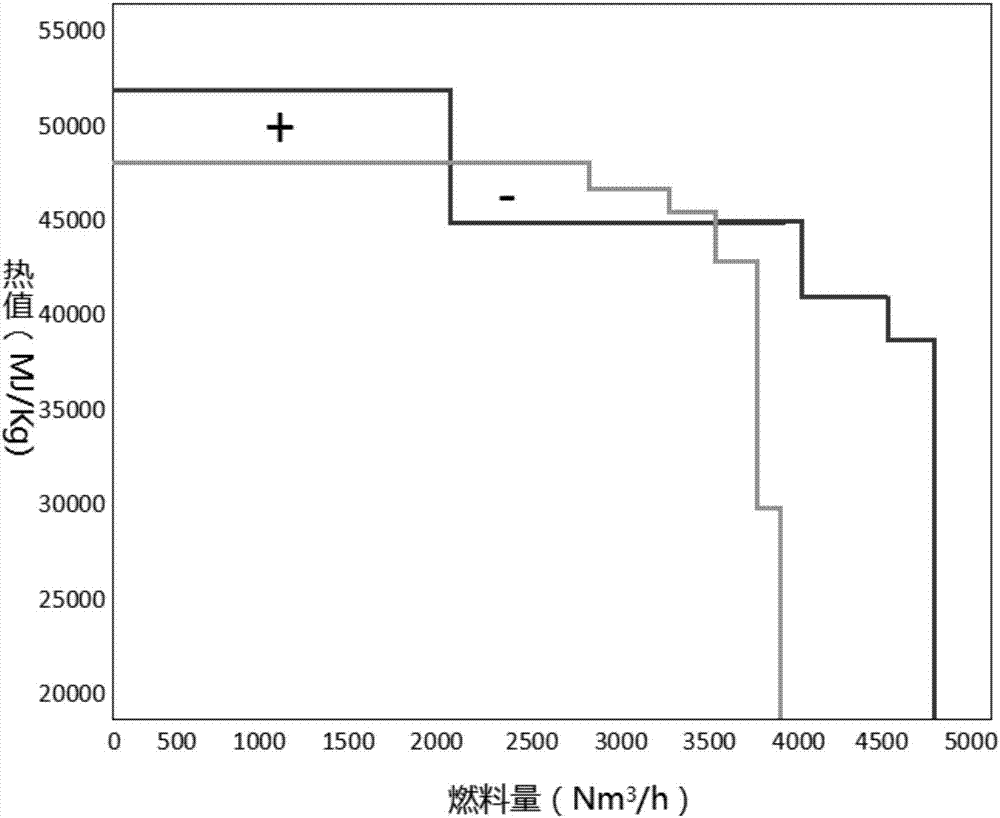

[0057] Step 3. Obtain the gas output and calorific value of the gas by-produ...

Embodiment 2

[0133] Another embodiment of the present application also provides an optimization system 3 of the fuel gas system based on calorific value balance, such as Figure 6 As shown, the optimization system includes:

[0134] The monitoring unit 31 is used to improve the instruments in the fuel gas system, and monitor the production-consumption balance and fuel calorific value in the fuel gas system based on the improved instruments;

[0135] The processing unit 32 is used to obtain the historical operating data of the heating furnace from the real-time database, divide the fuel consumption of the heating furnace into at least two operating intervals according to the historical operating data, and construct the relationship between the efficiency of the heating furnace and the calorific value of the fuel in each operating interval. The correlation function among them is obtained by solving the fuel calorific value corresponding to the maximum efficiency of the heating furnace in eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com