Closed-type powder spraying coating system

A closed, coating technology, applied in spraying devices, liquid spraying devices, spray booths, etc., can solve the problems of cumbersome steps, powder waste, powder spillage, etc., and achieve the effect of simple operation process and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

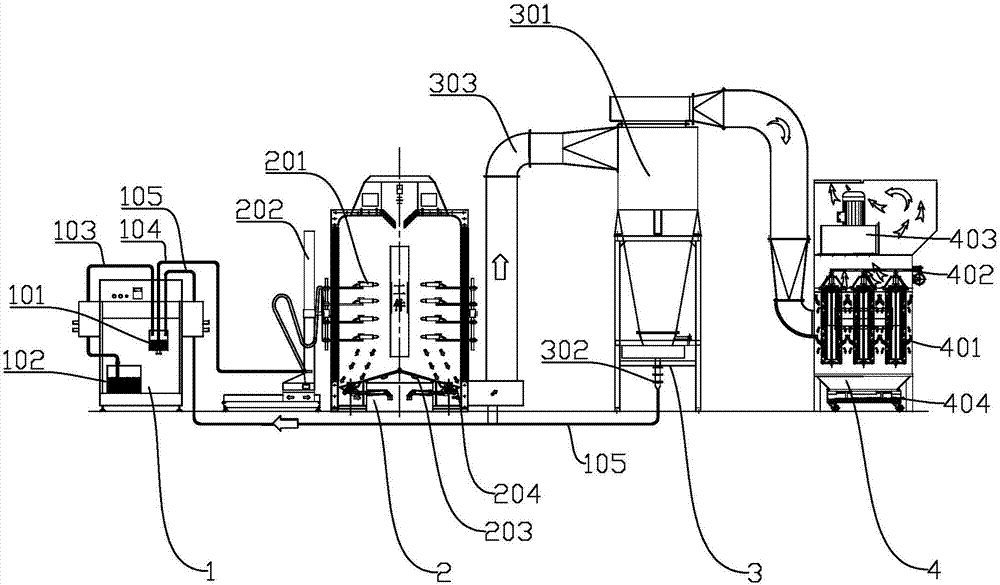

[0033] refer to Figure 1 to Figure 5 , the present invention is a closed type powder spraying coating system, comprising,

[0034] Powder supply system 1, the powder supply system 1 is used to supply powder for coating;

[0035] A spray booth 2, which is connected to the powder supply system 1 for spraying workpieces;

[0036] A recovery device 3, the recovery device 3 is connected to the spray booth 2 and the powder supply system 1, and is used to collect excess powder in the spray booth 2, and separate the reusable powder and send it to the powder supply system 1;

[0037] A micropowder collection device 4, the micropowder collection device 4 is connected to the recovery device 3, and is used to collect the fine powder separated by the recovery device 3;

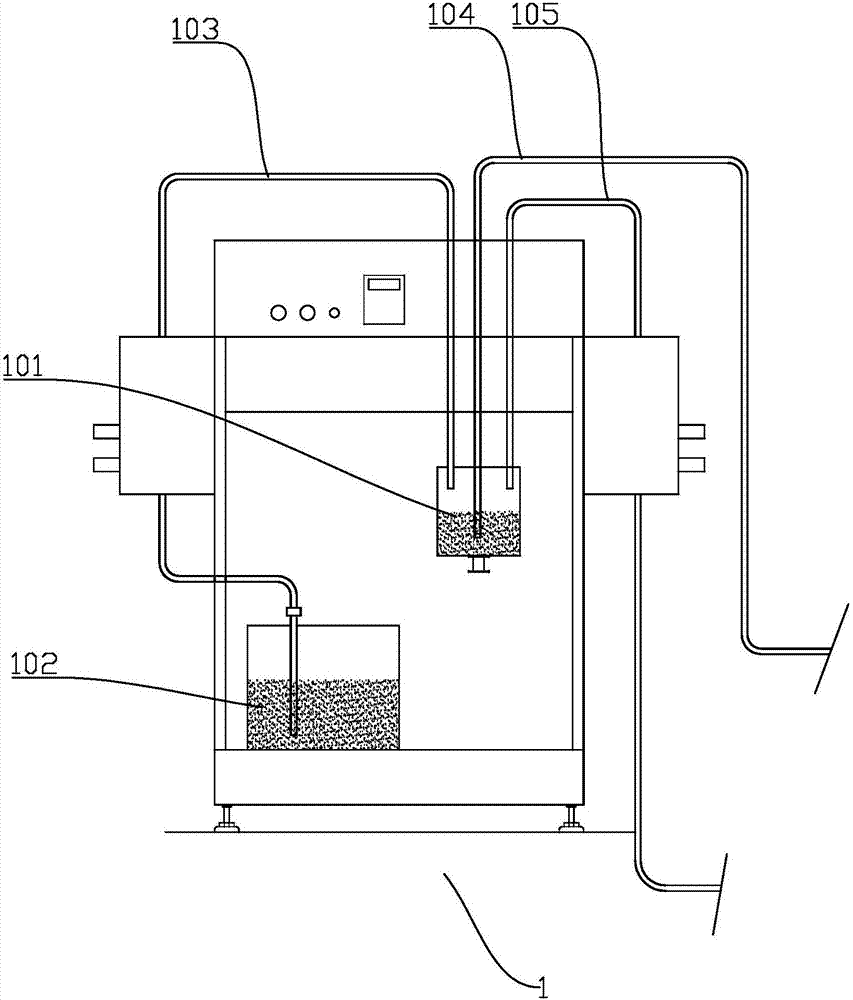

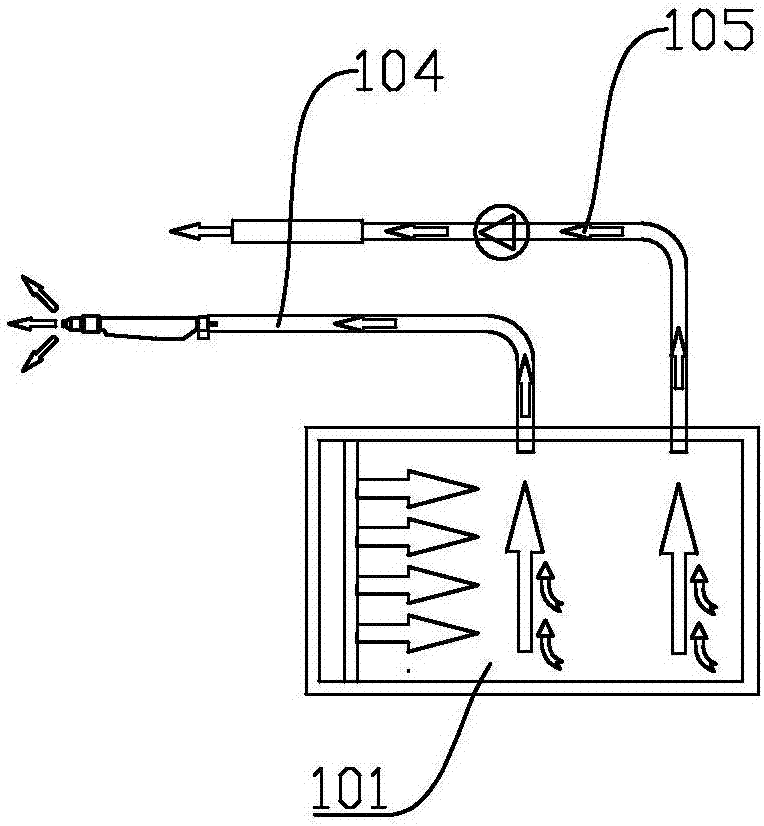

[0038] Wherein, the powder supply system 1 is provided with a first powder box 101, the first powder box 101 is a closed box structure, and the first powder box 101 is equipped with:

[0039] A powder inlet pipe 103, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com