Numerically-controlled lathe trimming device

A technology of trimming device and CNC lathe, which is applied in the direction of auxiliary devices, turning equipment, toolholder accessories, etc., can solve the problems of no convenient operation, no effect of use, and inconvenience of users, so as to save time and energy and ensure the trimming effect , Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

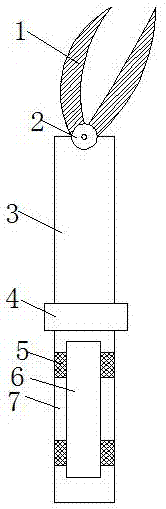

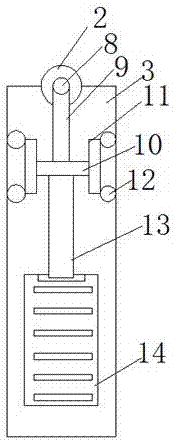

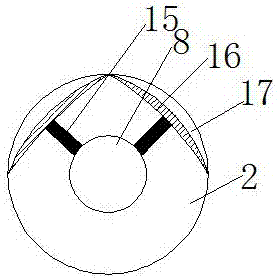

[0017] refer to Figure 1-3 , a CNC lathe pruning device, comprising a device main body 3, a lifting device 7 is installed on the device main body 3 through a connecting rod 4, a telescopic kit 6 is installed in the inner cavity of the lifting device 7, and the telescopic kit 6 passes through the connecting plate 5 and the lifting device 7 The inner wall is connected, the upper end of the device main body 3 is equipped with a connecting shaft 2 through a connecting shaft 8, and both sides of the outer end of the connecting shaft 2 are provided with a card slot 17, and the inner wall of the card slot 17 is equipped with a fixing device 16, and the connecting shaft 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com