Composite reactive black dye

A technology of reactive black and dyes, applied in the field of dyes, can solve problems such as unsatisfactory blackness, color difference between head and tail, color difference between sides, etc., and achieve the effect of similar structure, good compatibility, excellent fastness performance, and high color fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

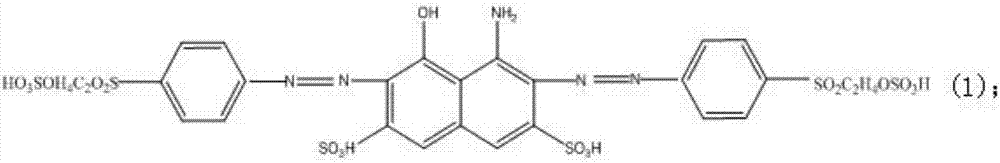

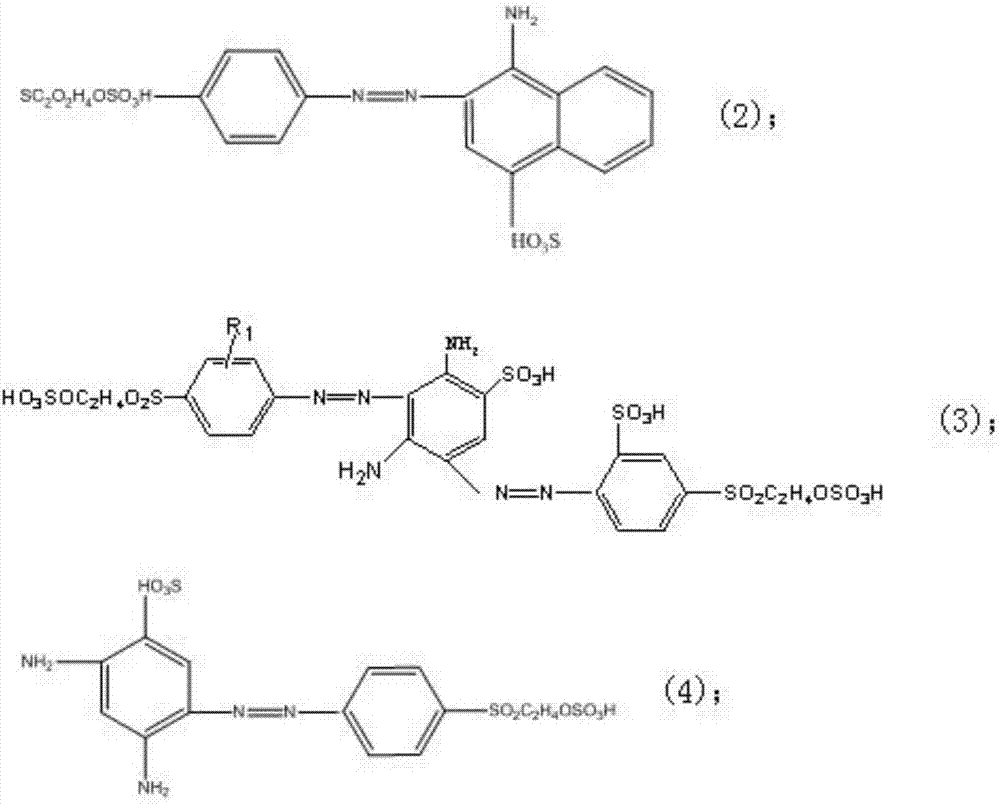

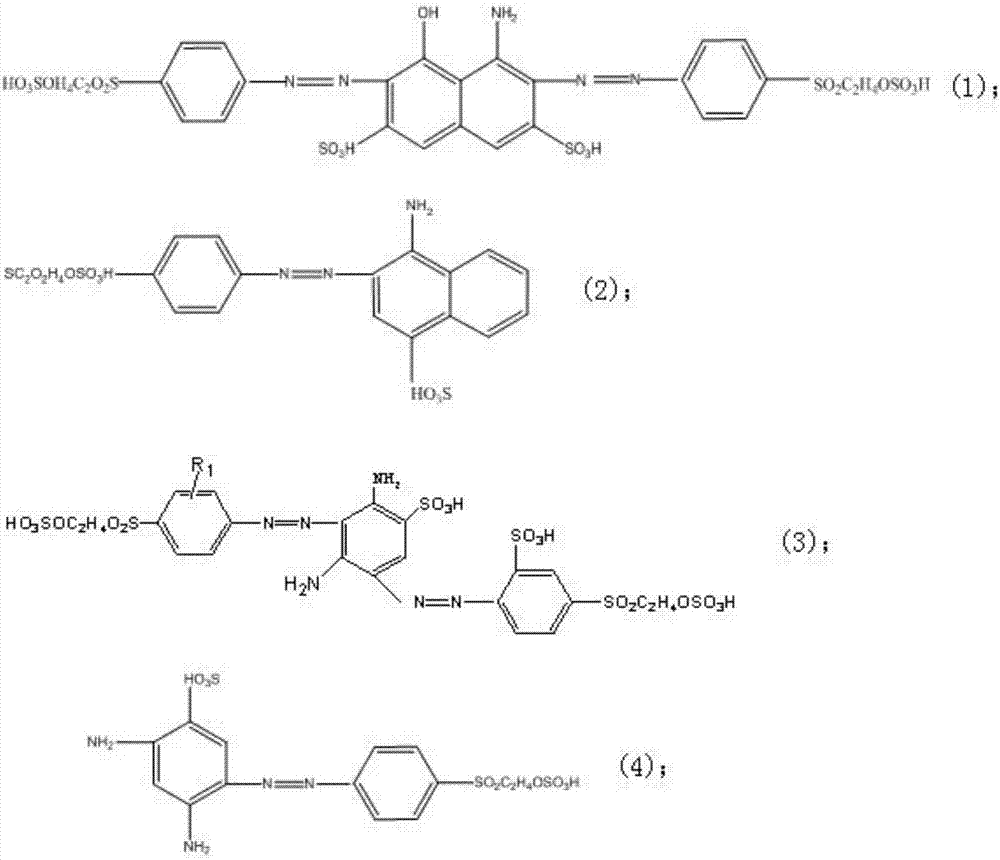

[0023] Select the dyestuff of four structural formulas as formula (1), formula (2), formula (3) and formula (4), according to the parts by weight measurement data shown in table 1, formula (1) dyestuff, formula (2) After the dye, the dye of formula (3), the dye of formula (4) and the auxiliary agent are blended, fully mechanically mixed, the composite reactive black dye can be obtained. Wherein, the auxiliary agent can be commonly used auxiliary agent such as leveling agent (such as Pingping plus O), dyeing accelerator (such as salt or Yuanming powder), surfactant (such as sodium dodecylbenzene sulfonate), dispersant ( Such as one of polyacrylic acid) or its mixture in any proportion, it can also be functional additives added for different purposes such as softener (such as ester quaternary ammonium salt), dustproof agent (such as water-soluble dustproof agent), One of the antistatic agents (such as antistatic agent SN) or a mixture in any proportion. The composite reactive b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com