A method for improving heat exchange efficiency after fracturing of hot dry rock

A technology of heat exchange efficiency and hot dry rock, applied in earthwork drilling, wellbore/well components, production fluid, etc. Problems such as forming heat exchange paths to achieve the effects of reducing development costs, promoting heat exchange, and improving circulation paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

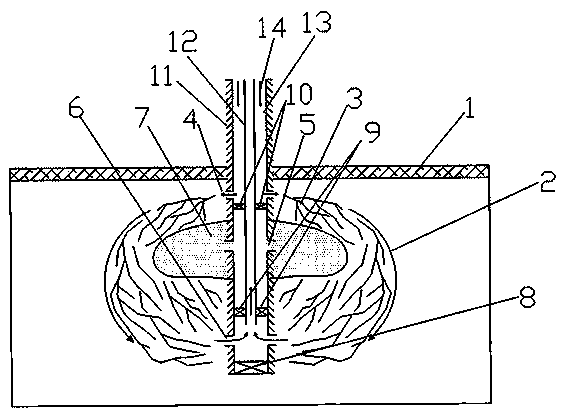

[0028] see figure 1 As shown, a method for improving heat exchange efficiency after hot dry rock fracturing includes the following steps:

[0029] 1. Select the hot dry rock reservoir 2, use drilling equipment to drill through the hot dry rock caprock 1, and drill to the bottom area of the hot dry rock reservoir 2;

[0030] 2. After lifting out the drilling tool, run the production casing 13 and the bottom hole packer 8 with a thermal conductivity greater than 90W / (m·K) along the drilling trajectory, and use a high-temperature heat-resistant thermal conductivity greater than 8W / (m·K) Cement 7 cementing;

[0031] 3. Lower the perforating equipment into the hot dry rock fracturing target reservoir, shoot through the production casing 13, the cement sheath 11 and the hot dry rock reservoir 2 to form the hot dry rock fracturing holes 5, and the hot dry rock fracturing According to actual engineering needs, 2-4 holes are evenly arranged in the circumferential direction, and 1-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com