A Prediction Method of Dry Gas Huff and Puff Effect in Tight Condensate Gas Reservoirs with High Water Cut

A condensate gas reservoir, compact technology, used in earth-moving drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

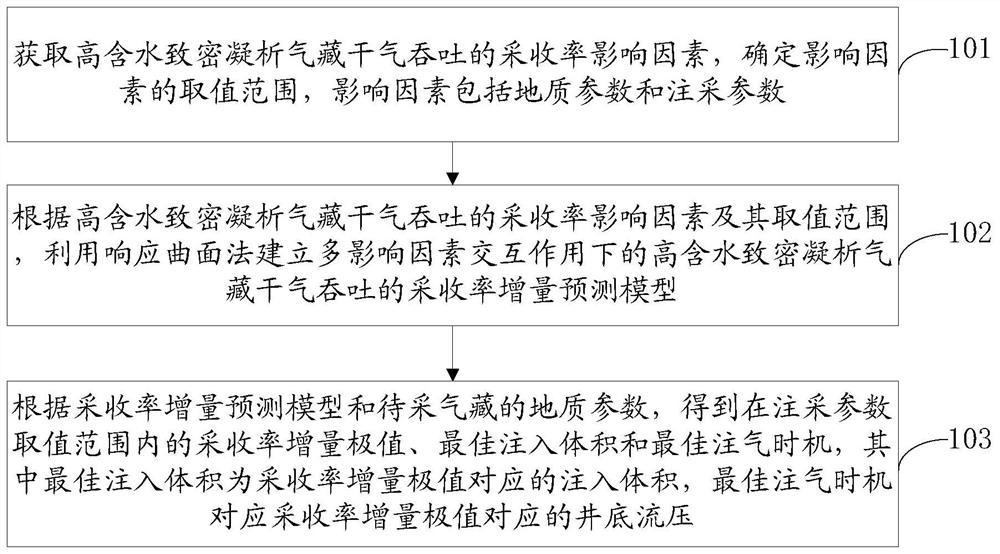

[0059] This example provides a method for predicting the effect of dry gas huff and puff in tight gas condensate reservoirs with high water cut, see figure 1 , the method flow is as follows:

[0060] Step 101: Obtain factors influencing recovery of dry gas huff and puff in tight condensate gas reservoirs with high water content, and determine the value range of the factors, which include geological parameters and injection-production parameters;

[0061] Specifically, in order to study the effect of dry gas huff and puff in high water-cut tight condensate gas reservoirs, firstly, from the perspective of geological parameters, the factors affecting the recovery of high water-cut tight condensate gas reservoirs are comprehensively analyzed. The main geol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com