Coal mine return air crossheading roadway non-repetitive supporting outfit

A technology of return air trough and support device, applied in mining equipment, mine roof support, transportation and packaging, etc., can solve problems such as accelerated roof damage, and achieve the effects of ensuring integrity, flexible operation, and quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

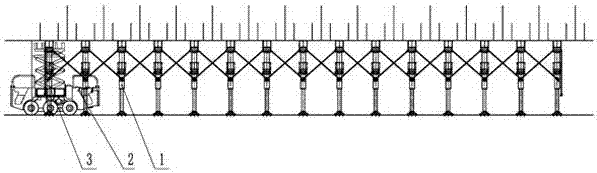

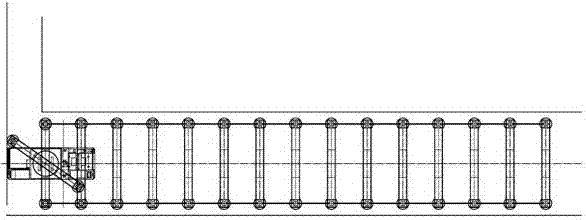

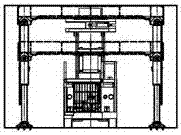

[0052] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0053] A complete set of non-repeated support equipment for a coal mine return air tunnel roadway, including a single-span support device 1, a transport vehicle 2 for the downstream support device, and a quick joint assembly plate 3. The single-span support device 1 includes a crossbeam 4 , a column 5 , a support base 6 , a pin 7 , a chain 8 , a shackle 9 , and a claw hook 10 . The transport vehicle 2 of the trough support device includes a trackless explosion-proof rubber-tyred vehicle 11 , a lifting platform 12 , a rotating clamping device 13 , an emulsion pump 14 , and an emulsion tank 15 . The quick joint combination board 3 includes two quick joint females and two quick joint males.

[0054] The single-span supporting device 1 is mainly connected to two ends of the crossbeam 4 by a column 5 through a pin shaft. The bottom of the column 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com